The Importance of Coil Slitting in San Diego’s Manufacturing Sector

The city of San Diego, known for its picturesque beaches and thriving tech scene, is also home to a robust manufacturing sector that is continuously evolving to meet the demands of various industries. Among the many processes integral to this sector, coil slitting stands out as a crucial technique employed in the fabrication of metal products. This article explores the significance of coil slitting in San Diego, its processes, and its impact on various industries.

Coil slitting is a manufacturing process that involves cutting large rolls of metal coils into narrower strips. These strips can then be used for a wide range of applications, including automotive components, construction materials, and appliance manufacturing. In a city like San Diego, where industries such as aerospace, defense, and high-tech manufacturing thrive, the ability to produce precise metal strips is fundamental to maintaining the quality and functionality of various products.

The Coil Slitting Process

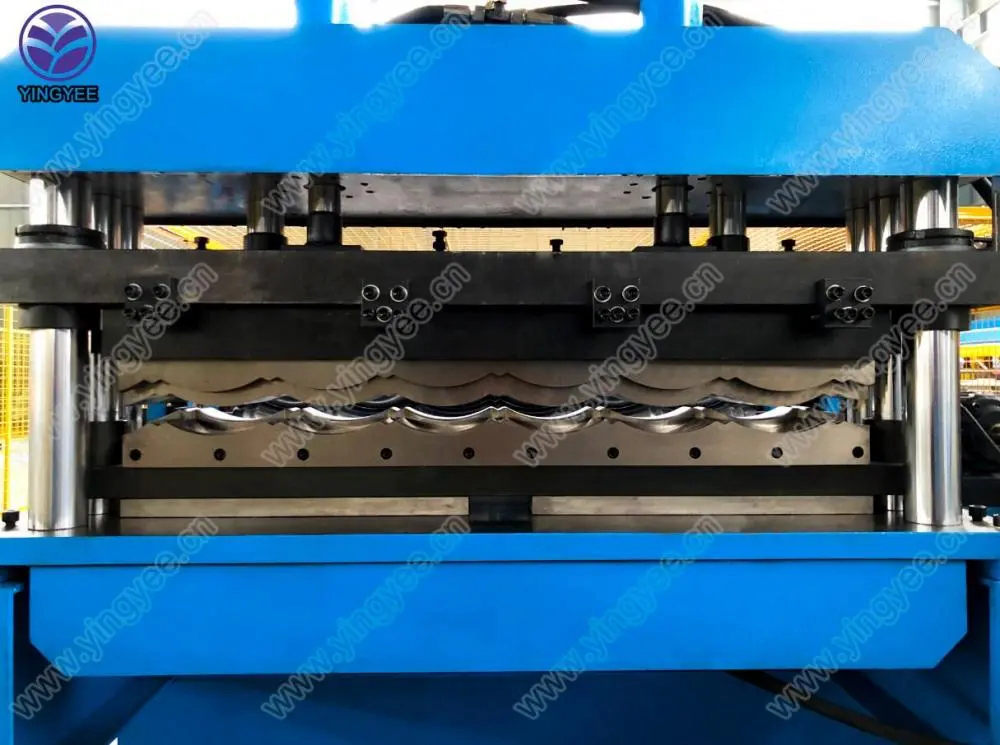

The coil slitting process begins with the selection of the appropriate metal coil, which can be made from various materials, including stainless steel, aluminum, copper, and carbon steel. Once the coil is chosen, it is loaded onto a slitting machine designed to efficiently cut the coil into the desired widths. The machine utilizes a series of sharp blades that slice through the metal with precision, ensuring a clean cut that minimizes waste.

Several factors are critical in the coil slitting process, including the speed and accuracy of the slitting machine, the thickness of the metal, and the desired width of the strips. In San Diego, manufacturers are increasingly investing in advanced technologies, such as computer numerical control (CNC) systems, which enhance the precision of cutting and improve overall efficiency. This technological advancement is vital for meeting the stringent quality standards required in industries like aerospace and medical devices.

Applications of Coil Slitting in San Diego

San Diego's diverse manufacturing landscape benefits greatly from coil slitting. One of the most prominent applications is in the aerospace industry, where precision-engineered components are essential for aircraft performance and safety. Coil slitting allows manufacturers to produce lightweight yet strong parts that meet the rigorous standards set by governing bodies like the Federal Aviation Administration (FAA).

Additionally, the construction industry in San Diego utilizes coil slitting for producing metal roofing, framing, and other structural components. The ability to create custom widths and lengths of metal strips allows builders and contractors to offer tailored solutions that meet the specific needs of various construction projects.

The appliance manufacturing sector also relies on coil slitting for producing components used in refrigerators, washers, dryers, and other household appliances. With consumer demand for high-quality products growing, manufacturers in San Diego must ensure that every component is produced with precision to handle both aesthetic and functional requirements.

Challenges and Future Trends

While coil slitting continues to play a vital role in San Diego's manufacturing sector, it is not without challenges. The fluctuating prices of raw materials, environmental regulations, and the need for sustainable practices are major concerns for manufacturers. As industries become more aware of their environmental footprints, there is an increasing push towards recycling metal coils and adopting green manufacturing processes.

Looking ahead, the future of coil slitting in San Diego appears optimistic. The continuous advancement of manufacturing technologies, coupled with the city’s commitment to innovation, is likely to enhance the efficiency and sustainability of coil slitting operations. Furthermore, as new materials and applications emerge, manufacturers will need to adapt their processes, fostering an environment that encourages growth and adaptation.

Conclusion

In summary, coil slitting is an essential process within San Diego’s manufacturing sector, enabling the production of high-quality metal components for a variety of industries. As technological advancements continue to shape the landscape of manufacturing, the significance of precise processes like coil slitting cannot be overstated. With its strategic location and a skilled workforce, San Diego is well-positioned to remain a leader in manufacturing, ensuring that coil slitting will continue to play a pivotal role in the development of innovative and reliable products for years to come.