Understanding the Coil Metal Cut to Length Line A Comprehensive Overview

In the realm of metal fabrication, the coil metal cut to length line stands as a pivotal system that enhances efficiency, precision, and versatility in producing metal sheets. This process is crucial for manufacturers who require specific lengths of metal for various applications, from automotive components to construction materials.

A coil metal cut to length line typically begins with large coils of metal, which can be made of steel, aluminum, or other alloys. These coils are unwound and fed through a series of sophisticated machines that perform several key operations. The primary function of the cut to length line is to cut these coils into sheets of predetermined lengths without compromising the integrity of the metal.

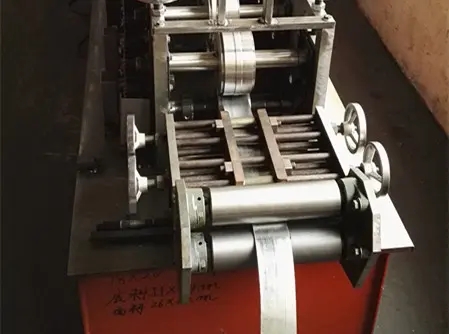

The process starts with the uncoiling device, where the coil is mounted and unwound. As the coil feeds into the line, it passes through a leveler. This critical step removes any curvature or defects present in the metal, ensuring that it is flat and uniform. Following the leveling process, the metal moves toward the cutting station.

At the cutting station, the metal is sheared to the desired length using precision cutting blades. This operation can be done via various methods, including rotary shearing or guillotine cutting, depending on the intended application and thickness of the metal. Accuracy is paramount in this stage, as any deviation in length can lead to material waste and increased costs for manufacturers.

Once the metal sheets are cut to the specified length, they may undergo additional processing, such as edge trimming or surface treatment. The cut sheets can be bundled and packaged for storage or further distribution, making the entire process both efficient and effective.

The advantages of using a coil metal cut to length line are numerous. Firstly, the automation of this process significantly increases production speed, allowing manufacturers to meet high demand without sacrificing quality. Additionally, the precision of cuts reduces material waste, leading to cost savings in production.

Another benefit is the flexibility offered by these systems. Manufacturers can adjust the parameters of the cut to length line to produce various sheet sizes, accommodating diverse project requirements. This adaptability is crucial in today’s fast-paced manufacturing environment, where customization and quick turnaround times are essential.

In conclusion, the coil metal cut to length line is an indispensable piece of equipment in modern metal fabrication. It combines efficiency, precision, and versatility, enabling manufacturers to produce high-quality metal sheets tailored to their specific needs. As industries continue to evolve, the importance of such systems will only grow, solidifying their role in the production landscape.