The Importance of Coil Slitting Lines in Modern Manufacturing

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. One of the key processes that contribute significantly to achieving these goals is the coil slitting line. This highly specialized machinery plays an essential role in transforming large metal coils into narrower strips that meet various industry specifications. Understanding the functioning and significance of coil slitting lines can shed light on their crucial role in modern manufacturing.

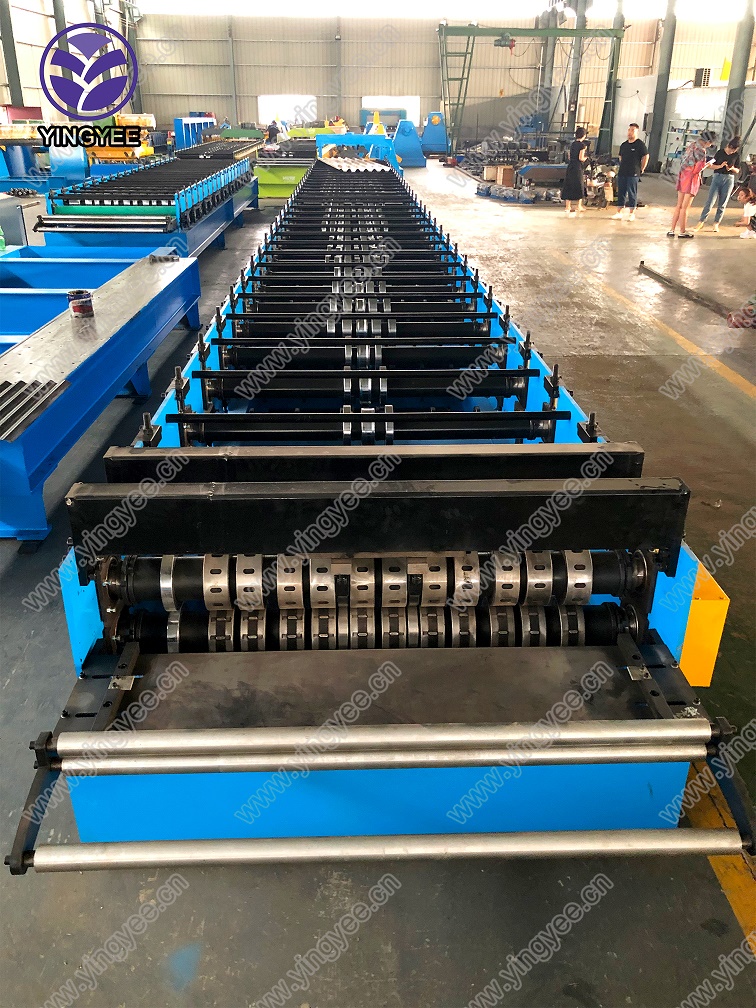

At its core, a coil slitting line is designed to take wide coils of material, typically steel or aluminum, and cut them into multiple narrower coils. The process begins with the unwinding of the parent coil, which is then fed into a series of slitting blades. These blades are adjustable, allowing manufacturers to customize the width of the resulting strips according to specific requirements. After slitting, the newly formed coils are recoiled onto separate mandrels for easy handling and storage.

One of the main advantages of a coil slitting line is its ability to enhance productivity

. The automated nature of modern slitting lines means that they can operate at high speeds, cutting large volumes of material with minimal downtime. This efficiency not only leads to increased output but also reduces labor costs, as fewer operators are required to manage the process. This is particularly important in industries where demand for metal strips is high, such as automotive, construction, and appliance manufacturing.

Precision is another critical aspect of coil slitting lines. The quality of the finished product is paramount in industries that rely on narrow metal strips for further processing. Any inconsistencies in width or thickness can lead to defects and inefficiencies downstream. Advanced coil slitting lines are equipped with state-of-the-art technology that ensures tight tolerances and uniformity. Features such as laser measuring systems and automated controls allow for constant monitoring and adjustments during the slitting process, guaranteeing high-quality outputs.

Moreover, coil slitting lines are designed with versatility in mind. Manufacturers often require different widths and materials for various applications. Modern slitting lines can accommodate a range of materials, including various grades of steel and aluminum, as well as non-ferrous metals. Additionally, they can be easily reconfigured to switch between different production runs. This adaptability is essential in a market that demands quick turnaround times and customized solutions.

Another significant advantage of coil slitting lines is their contribution to waste reduction. When coils are processed efficiently, there is less scrap metal generated in the production process. Advanced technology also enables manufacturers to optimize their material usage, ensuring that the maximum amount of usable strips is produced from each coil. This waste minimization not only helps to reduce costs but also aligns with the growing emphasis on sustainability in manufacturing practices.

In conclusion, coil slitting lines are vital to the manufacturing industry, serving as the backbone for producing high-quality metal strips with efficiency and precision. Their ability to enhance productivity, ensure accuracy, offer versatility, and minimize waste makes them indispensable in a variety of sectors. As technology continues to advance, the role of coil slitting lines will likely expand, further solidifying their place in modern manufacturing processes. Businesses that invest in state-of-the-art slitting lines position themselves to meet the evolving demands of their industries while maintaining a competitive edge.