Close Deck Floor Roll Forming Machine Enhancing Structural Efficiency

In the realm of modern construction, efficiency and durability are paramount. One of the key innovations that have emerged to meet these demands is the Close Deck Floor Roll Forming Machine. This advanced piece of equipment is revolutionizing the way floor systems are constructed, offering numerous advantages in both design and application.

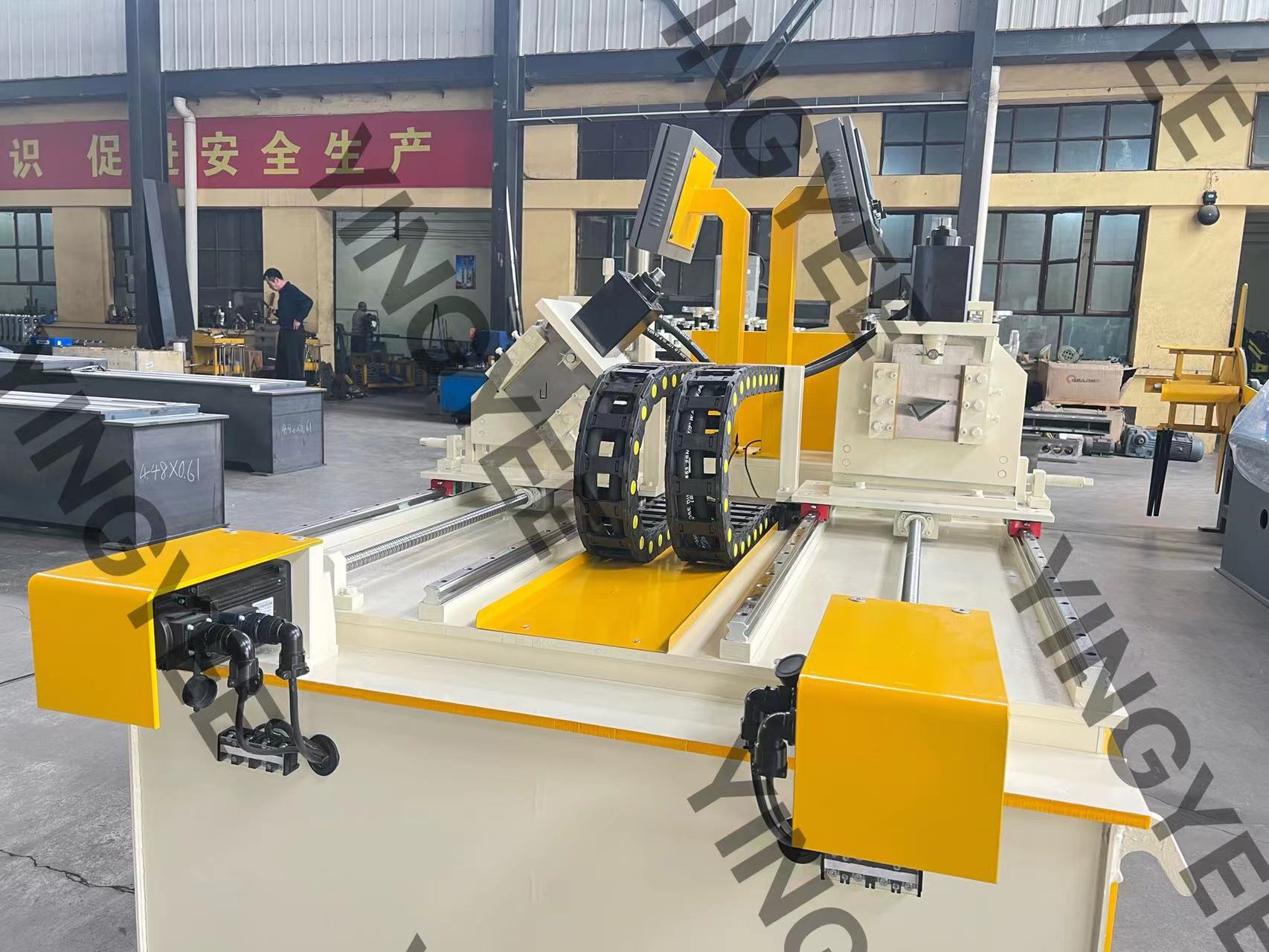

The Close Deck Floor Roll Forming Machine specializes in producing high-quality floor decking sheets that are essential for constructing robust and lightweight flooring systems. Utilizing a continuous roll forming process, this machine efficiently transforms steel coils into finished products with precise dimensions and consistent quality. The term close deck refers to the design of the floor panels, which feature closely spaced ribs and a smooth surface, optimizing both strength and aesthetic appeal.

One of the primary benefits of using a Close Deck Floor Roll Forming Machine is its ability to create structurally sound flooring solutions that can bear heavy loads while minimizing weight. This characteristic is particularly beneficial in multi-story buildings where weight reduction leads to lower foundation costs and enhanced seismic performance. The close deck profile provides superior load distribution, making it ideal for commercial and industrial applications.

Moreover, this machinery allows for significant customization in terms of thickness, width, and length of the floor panels. Manufacturers can produce tailored solutions to meet specific requirements, ensuring that each project can achieve its desired performance standards. The adaptability of the Close Deck Floor Roll Forming Machine is a significant advantage in today’s construction landscape, where unique architectural designs and client needs often come into play.

Additionally, the efficiency of the roll forming process reduces wastage. By utilizing continuous production methods, the machine minimizes offcuts and ensures that materials are used optimally. This not only contributes to sustainability but also improves the overall cost-effectiveness of construction projects.

In operation, the Close Deck Floor Roll Forming Machine offers high speed and precision. Advanced control systems and automation facilitate seamless production, allowing manufacturers to meet tight deadlines without compromising quality. This reliability in production translates into faster project completion times, a crucial factor in the competitive construction market.

Furthermore, the use of high-strength materials combined with the close deck design ensures superior resistance to corrosion and wear. This longevity means that floors produced with this machinery require less maintenance and offer excellent performance over the lifespan of the building.

In conclusion, the Close Deck Floor Roll Forming Machine is redefining the standards of flooring construction. Its ability to produce lightweight yet strong floor panels enhances structural efficiency, reduces costs, and meets the diverse needs of modern architecture. As the construction industry continues to evolve, innovations like the Close Deck Floor Roll Forming Machine will be at the forefront, driving progress towards more effective and sustainable building practices. As we look to the future, embracing such technologies will be crucial in meeting the growing demands of urbanization and infrastructure development.