The China Type Rolling Machine Revolutionizing Metal Forming

In the world of metal fabrication, the rolling machine stands out as a cornerstone of production technology. Among the various types, the China type rolling machine has gained prominence due to its efficiency, versatility, and technological advancements. This machine is specifically designed to roll metal sheets and plates into various shapes, such as cylinders, cones, and other custom forms, which are integral to numerous industries, ranging from construction to automotive.

Design and Features

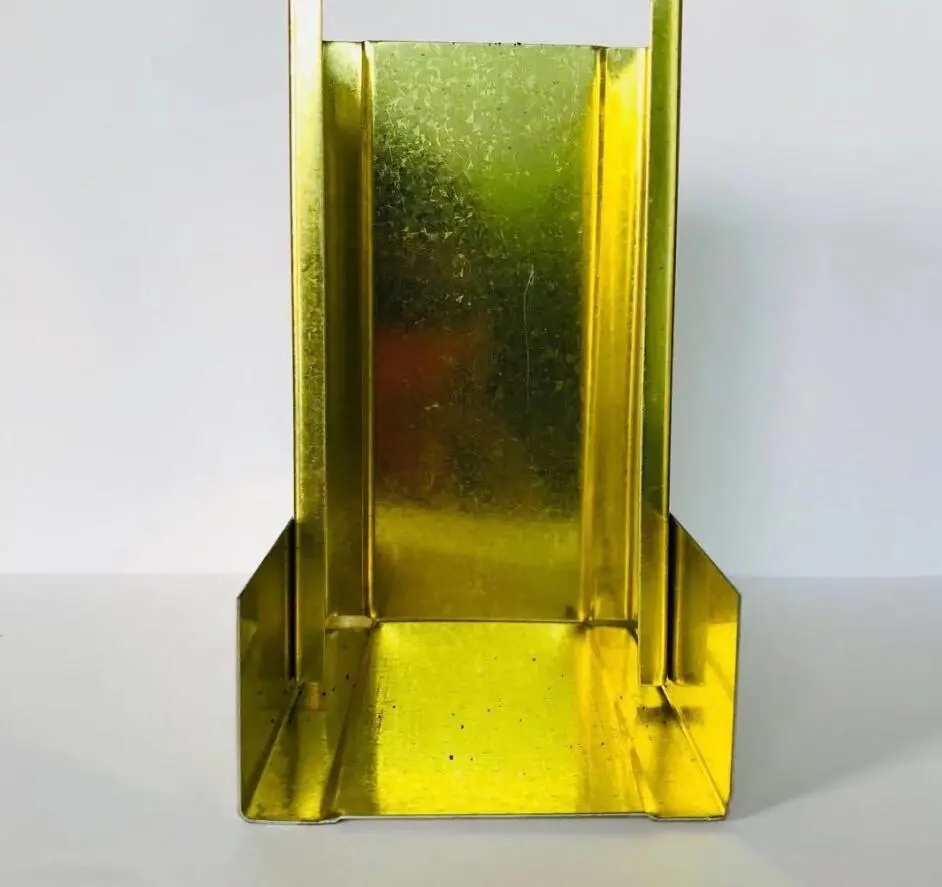

The China type rolling machine is characterized by its robust design and user-friendly features. Typically, it consists of three main rollers two lower rollers that provide stability and support, and one upper roller that performs the rolling action. This configuration allows for superior control over the material being processed, enabling operators to achieve precise dimensions and shapes. Advanced models come equipped with digital displays and programmable settings, allowing for seamless adjustments and reducing the chances of human error.

One notable aspect of these machines is their ability to handle various materials, including mild steel, stainless steel, and aluminum. This versatility makes them valuable in industries that require different types of metalworking. Additionally, the rolling process can be performed in both hot and cold conditions, further enhancing the machine's adaptability to specific production needs.

Efficiency and Productivity

One of the significant advantages of the China type rolling machine is its efficiency. With high-speed operation capabilities, these machines can significantly reduce the time taken for metal forming processes. This enhancement in productivity is especially beneficial in manufacturing environments where time is of the essence. Moreover, the machines are designed to minimize waste material, maximizing the yield from each metal sheet or plate used.

The energy consumption of these machines is also optimized, making them an eco-friendly choice in the metalworking industry. Many manufacturers have embraced energy-efficient technologies in line with global sustainability goals, ensuring that the rolling processes not only produce excellent results but do so with a lower environmental impact.

Applications in Various Industries

The applications of the China type rolling machine are numerous, reflecting its importance in modern manufacturing. In the construction industry, these machines are utilized to create structural components, including girders and beams, that are essential for building frameworks. Moreover, the automotive sector relies on rolled metals for producing parts such as exhaust systems, chassis components, and more.

Additionally, the shipbuilding and aerospace industries benefit from the precise rolled components that these machines can produce. The ability to create complex shapes with exact specifications is crucial, as it ensures safety and functionality in high-stakes applications.

Conclusion

In conclusion, the China type rolling machine embodies a blend of innovation, efficiency, and adaptability that has revolutionized the metal forming landscape. With its robust design and ability to work with various materials and shapes, it serves as an indispensable tool across numerous industries. As technology continues to advance, we can expect further enhancements in rolling techniques and machines, propelling the industry into new frontiers of efficiency and sustainability. The future looks promising for those who leverage the capabilities of rolling machines, enabling them to meet the ever-increasing demands of modern manufacturing.