Understanding the China Sandwich Panel Production Line

In recent years, sandwich panels have become increasingly popular in the construction industry, particularly for their excellent insulation properties and versatility. These panels, composed of two outer layers and a core material, are widely used for thermal insulation in various applications, including walls, roofs, and even floors. As the demand for energy-efficient building materials rises, the establishment of robust production lines for sandwich panels becomes crucial. In this context, China has emerged as a significant player in the sandwich panel production market.

What Are Sandwich Panels?

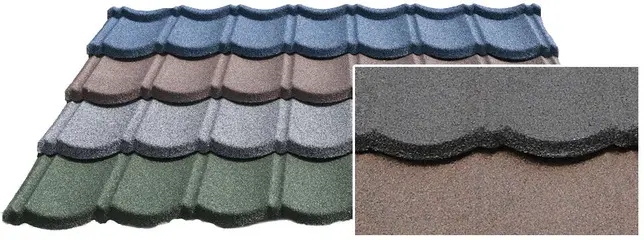

Sandwich panels consist of three layers two outer sheets and a lightweight core. The outer layers are typically made from metal, concrete, or other durable materials, while the core often consists of materials such as polyurethane, polystyrene, or mineral wool. This unique structure grants sandwich panels remarkable thermal insulation, soundproofing, and fire-resistant properties, making them an ideal choice for various construction projects.

The Importance of Production Lines

The efficiency of producing sandwich panels relies heavily on well-designed production lines. A dedicated production line ensures that manufacturers can produce high-quality panels consistently and at scale, meeting the growing demands of the market. In China, advanced production lines leverage cutting-edge technology and automation to streamline the manufacturing process from raw material handling to the finishing stage.

Components of a Sandwich Panel Production Line

1. Raw Material Preparation The first step in the production line involves preparing the raw materials. This includes cutting and handling metal sheets and core materials to the required specifications.

2. Core Material Application The core material is essential for the thermal and structural properties of the panel. Depending on the type of core (e.g., polyurethane, EPS, or mineral), different machinery is used to inject or place the core material between the outer sheets.

3. Pressing and Bonding Once the core material is in place, the panels are pressed to ensure strong adhesion between the layers. This critical step often involves high-pressure and temperature processes to activate the bonding agents.

4. Cutting and Trimming After pressing, the panels are cut to size according to customer specifications. This step might include trimming the edges for a clean finish and ensuring uniformity.

5. Quality Control Quality control is a vital part of the production line, involving inspections and testing to ensure that each panel meets industry standards. This may include tests for thermal insulation, fire resistance, and structural integrity.

6. Packaging and Shipping Finally, the finished sandwich panels are packaged for shipment to clients. Efficient packaging solutions help protect the panels during transport and facilitate easy handling.

Advantages of Chinese Production Lines

China's sandwich panel production lines have several advantages, making them competitive in the global market. Firstly, the country's robust manufacturing infrastructure allows for rapid scaling of production to meet demand. Secondly, advanced technology integration, such as automation and computer control systems, minimizes human error and maximizes efficiency. Additionally, the availability of a vast array of raw materials enables flexibility in choosing core and outer layer materials to suit diverse project requirements.

Environmental Considerations

The sandwich panel production process is not without its environmental concerns. However, many Chinese manufacturers are increasingly adopting sustainable practices, such as using eco-friendly materials and minimizing waste during production. Moreover, the energy-efficient properties of sandwich panels themselves contribute to sustainability by reducing heating and cooling costs in buildings.

Future Prospects

As global trends lean towards sustainable construction practices, the demand for sandwich panels is expected to grow. China's significant investment in technological advancement and production capabilities positions the country well for continued leadership in this market. Moreover, as the industry evolves, manufacturers are likely to explore innovative materials and designs that enhance the performance of sandwich panels even further.

Conclusion

In conclusion, the sandwich panel production line in China plays a vital role in the construction industry's ongoing evolution towards energy efficiency and sustainability. With advanced technologies and a focus on quality, Chinese manufacturers are well-equipped to meet the increasing worldwide demand for these versatile building materials. As the industry continues to innovate, the future of sandwich panels looks promising, marking a significant step forward in modern construction practices.