Understanding China Sandwich Panel Machine The Future of Construction

In recent years, the construction industry has witnessed a significant transformation, largely driven by technological advancements. One of the most noteworthy innovations is the sandwich panel machine, particularly those manufactured in China. This machine is revolutionizing how buildings are constructed, offering efficiency, speed, and sustainability that traditional methods struggle to match.

What is a Sandwich Panel?

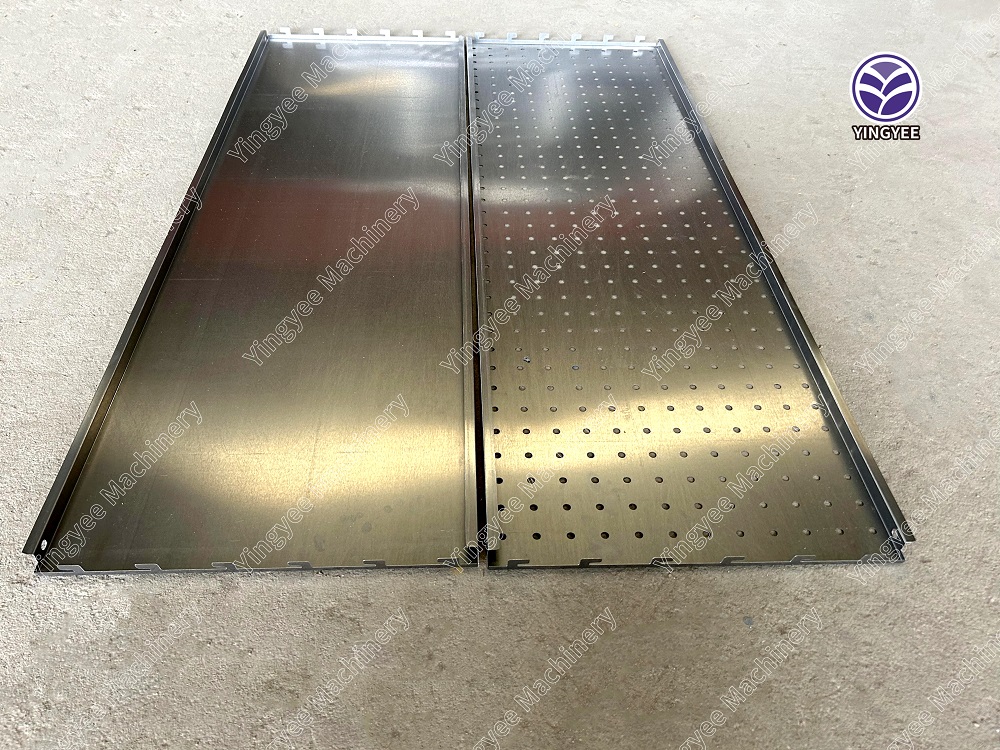

Before delving into the machine itself, it is essential to understand what a sandwich panel is. A sandwich panel consists of two outer layers, usually made of metal or other materials, enclosing a core that provides insulation. This core can be made from various materials, including polystyrene, polyurethane, or mineral wool. The unique structure of sandwich panels allows for excellent thermal insulation, soundproofing, and durability, making them ideal for a wide range of applications, from residential buildings to industrial facilities.

The Role of Sandwich Panel Machines

The sandwich panel machine specializes in the continuous production of these panels. Originating in China, these machines have incorporated advanced technology, allowing for high-speed production with outstanding precision. The automation of the production process not only enhances efficiency but also reduces labor costs, making it an attractive investment for construction companies.

Components of the Sandwich Panel Machine

A typical sandwich panel machine consists of several key components

1. Foam Injection System This system injects the insulating foam between the two outer layers, ensuring uniform thickness and density. The quality of the foam is crucial for achieving the desired insulation properties.

3. Cutting System The machine features an automated cutting system that precisely cuts the panels to the required lengths, minimizing waste and enhancing production efficiency.

4. Control Panel Modern machines are equipped with a user-friendly control panel that monitors the entire production process, allowing operators to adjust settings and ensure quality control.

Benefits of Using Sandwich Panel Machines

The advantages of utilizing sandwich panel machines are manifold

1. Speed of Production These machines can produce panels at an impressive rate, drastically reducing construction time. This is particularly beneficial for large-scale projects, where time is often a critical factor.

2. Cost-Effectiveness By automating the production process and reducing labor requirements, sandwich panel machines lower the overall costs associated with construction.

3. Versatility Sandwich panels can be tailored to meet specific requirements, including different thicknesses, sizes, and materials. This flexibility allows for a wide application range, from cold storage facilities to residential buildings.

4. Sustainability The materials used in sandwich panels are often recyclable, and their energy-efficient properties contribute to sustainable building practices. By using high-quality insulation, buildings consume less energy for heating and cooling, aligning with global efforts to reduce carbon footprints.

5. Lightweight Construction Sandwich panels are significantly lighter than traditional building materials, leading to reduced structural load and enabling the use of lighter frameworks. This can result in further cost savings in the foundation and overall structural design.

The Future of Construction

As the demand for innovative building solutions continues to grow, the sandwich panel machine stands out as a vital component of the modern construction industry. China, being a leader in manufacturing, has made significant strides in producing high-quality sandwich panel machines, making them accessible to construction companies worldwide. With their numerous advantages, these machines are likely to become increasingly prevalent, shaping the future of how buildings are designed and constructed.

In conclusion, the introduction of sandwich panel machines represents a paradigm shift in the construction industry. With their efficiency, cost-effectiveness, and sustainability, they are not just a trend but a viable solution for modern building challenges. As technology evolves, it is exciting to anticipate how these machines will continue to influence construction practices, leading to faster, safer, and more environmentally friendly building processes.