China Pipe Cutting Machine Factory A Leader in Precision Manufacturing

In the heart of China’s bustling manufacturing sector lies a prominent player in the field of pipe cutting technology the China pipe cutting machine factory. As global demand for high-quality, efficient cutting machines continues to rise, this factory emerges as a beacon of innovation, quality, and competitive pricing, meeting the needs of industries ranging from construction to automotive.

History and Evolution

The history of pipe cutting machines in China is marked by rapid technological advancements and increasing global competitiveness. Initially, the market was dominated by basic, manual pipe cutting tools. However, as industries grew and the need for precision increased, manufacturing processes evolved. Factories in China began adopting advanced technologies, including CNC (Computer Numerical Control) systems, which revolutionized the way pipes are cut, bent, and shaped.

Today, the China pipe cutting machine factory exemplifies this evolution. Through years of research and development, the factory has positioned itself at the forefront of the industry, integrating advanced automation and precision engineering to enhance productivity. This evolution not only reflects technological progress but also demonstrates the commitment of Chinese manufacturers to meet international standards.

State-of-the-Art Technology

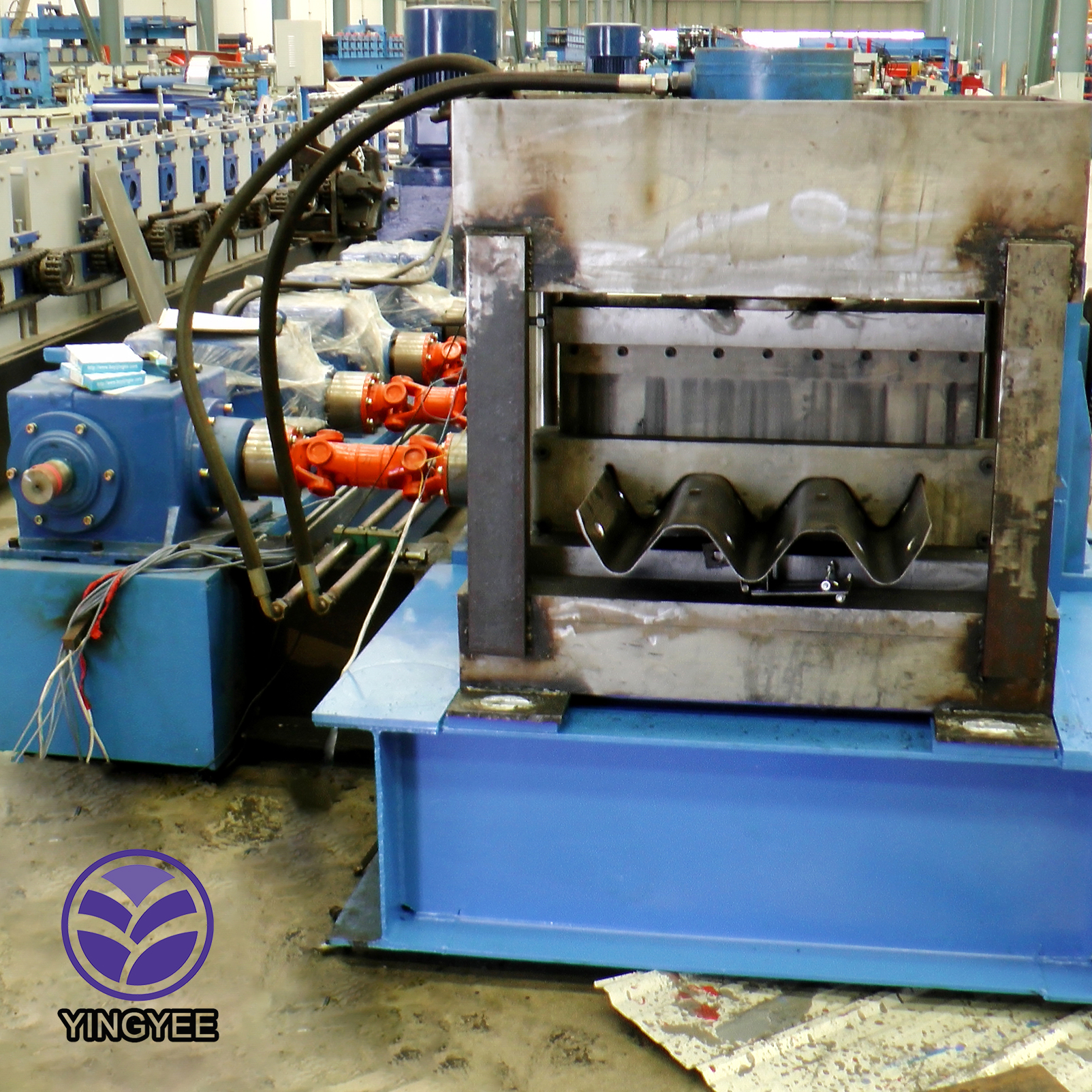

One of the key factors that sets the China pipe cutting machine factory apart from its competitors is its investment in state-of-the-art technology. The factory utilizes advanced CNC machines, laser cutting systems, and automated robotic arms, which contribute to high efficiency and precision. These technologies enable the factory to produce complex pipe shapes and cuts that are essential for modern industrial applications.

Laser cutting, in particular, has gained popularity due to its ability to deliver clean, precise cuts with minimal waste. The factory's machines can handle a wide range of materials, including steel, aluminum, and plastic, catering to a diverse set of customer needs. Additionally, the integration of smart technology allows for real-time monitoring and adjustments during the cutting process, ensuring optimal performance and quality control.

Quality Control and Standards

In the manufacturing world, quality is paramount. The China pipe cutting machine factory adheres to strict quality control measures throughout the production process. From the initial design phase to final assembly and testing, every step is meticulously monitored to ensure that each machine meets international standards.

The factory employs a team of skilled engineers and quality assurance specialists who conduct rigorous tests on every machine produced

. Certifications such as ISO9001 and CE mark further validate the factory's commitment to quality and safety, making its products not only reliable but also trusted by clients worldwide.Meeting Global Demand

As globalization progresses, the demand for high-quality pipe cutting machines has surged across the globe. The China pipe cutting machine factory has successfully tapped into this market by establishing a robust export network. The factory exports its machines to numerous countries, including the United States, Germany, Australia, and several Southeast Asian nations.

By catering to diverse market needs, the factory has built a solid reputation among international customers. Its ability to customize machines for specific applications and industries, combined with competitive pricing, makes it an attractive option for businesses looking for reliable cutting solutions.

Future Prospects

Looking ahead, the future of the China pipe cutting machine factory appears bright. With ongoing advancements in technology, the factory plans to expand its product line further, incorporating innovative features such as smart manufacturing and IoT (Internet of Things) capabilities. The goal is to enhance machine efficiency and provide customers with data-driven insights to optimize their operations.

Moreover, as industries increasingly focus on sustainability, the factory is committed to developing eco-friendly cutting machines that reduce energy consumption and minimize waste. By aligning with global sustainability trends, the factory aims to solidify its position as an industry leader in the years to come.

Conclusion

In summary, the China pipe cutting machine factory not only represents a significant player in the global manufacturing landscape but also embodies the spirit of innovation and quality associated with Chinese manufacturing. With its state-of-the-art technology, rigorous quality control, and commitment to meeting global demands, the factory is well-positioned for continued success. As industries evolve, this factory will undoubtedly play a crucial role in shaping the future of pipe cutting technologies worldwide.