Exploring the Advantages of China Light Keel Roll Forming Machines

In the realm of modern construction and manufacturing, the efficiency and precision of machinery play a crucial role in determining the quality and cost-effectiveness of production

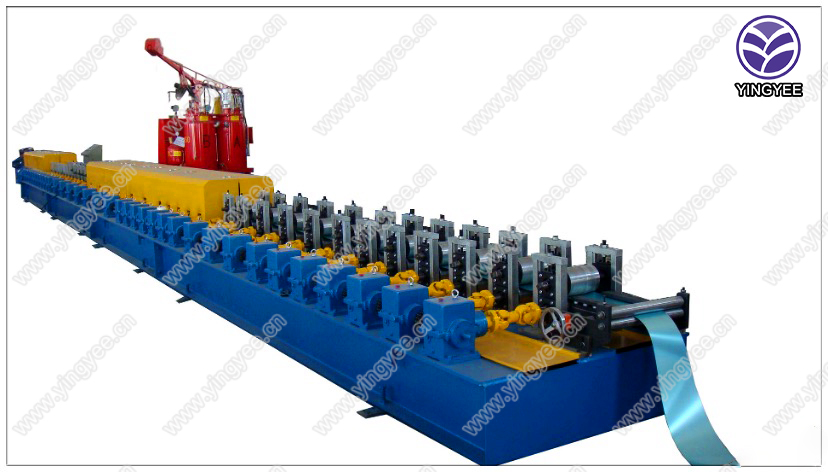

. Among these machines, the China light keel roll forming machine stands out as a pivotal tool for producing high-quality metal profiles that are essential in various applications, particularly in the construction industry.A light keel roll forming machine specializes in creating metal studs and tracks that are used in wall framing, ceilings, and other structural components. These machines are designed to produce lightweight, yet durable keels that provide the necessary support and framework for construction projects. With an increasing demand for lightweight materials that do not compromise structural integrity, the use of roll forming technology has seen significant growth.

One of the primary advantages of using a Chinese light keel roll forming machine is its efficiency. These machines are capable of producing high volumes of metal profiles in a short period, significantly reducing labor and manufacturing costs. By automating the roll forming process, manufacturers can achieve consistent product quality while minimizing human error. Additionally, the speed of production allows for quicker project completion times, giving businesses a competitive edge in the fast-paced construction market.

Precision is another key benefit of these machines. A light keel roll forming machine is engineered to produce accurate dimensions, which is critical for components that must fit together seamlessly. This precision ensures that when installed, the metal profiles provide the necessary strength and reliability expected in construction applications. The reduction of material waste also translates to cost savings for manufacturers, as they can utilize raw materials more effectively.

Moreover, the versatility of light keel roll forming machines cannot be overlooked. They can be customized to produce various profiles and designs to meet specific project requirements. This adaptability allows manufacturers to cater to the diverse needs of their clients, whether they are constructing residential buildings, commercial spaces, or industrial facilities.

China's advancements in technology and manufacturing processes have led to the creation of highly efficient and robust light keel roll forming machines. Many manufacturers now integrate advanced features, such as computerized controls and automatic feeding systems, which enhance operational efficiency and user-friendliness. This integration of technology also allows for remote monitoring and diagnostics, ensuring that machines operate smoothly and reducing downtime for maintenance.

Sustainability is also becoming an important factor in the construction industry. The use of light metal profiles not only reduces the overall weight of structures but also promotes the use of recyclables as the primary raw material. The production process of roll forming minimizes energy consumption compared to traditional manufacturing methods, aligning with global trends toward sustainable construction practices.

In conclusion, the China light keel roll forming machine represents a significant technological advancement in the production of metal profiles for the construction industry. Its efficiency, precision, versatility, and sustainability make it an invaluable tool for contractors and manufacturers alike. As construction demands continue to evolve, these machines will undoubtedly play a crucial role in shaping the future of building practices, enhancing both economic viability and structural performance.