Understanding China’s Gutter Forming Machines An Industry Overview

In the realm of modern construction and architecture, gutter systems play a crucial role in ensuring effective water drainage and protecting buildings from water damage. As the demand for high-quality gutter systems rises, the manufacturing of gutter forming machines in China has gained significant attention. These machines streamline the process of producing gutters, enhancing efficiency and precision for various applications across the construction industry.

The Importance of Gutter Systems

Gutter systems are essential for the longevity of any structure. They prevent water accumulation on roofs and direct rainwater away from buildings, foundations, and landscaping. When properly installed, gutters reduce the risk of leaks, mold growth, and structural damage. Understanding the need for efficient gutter production, many construction businesses are turning to advanced machinery that can deliver consistent and high-quality results.

Gutter Forming Machines An Overview

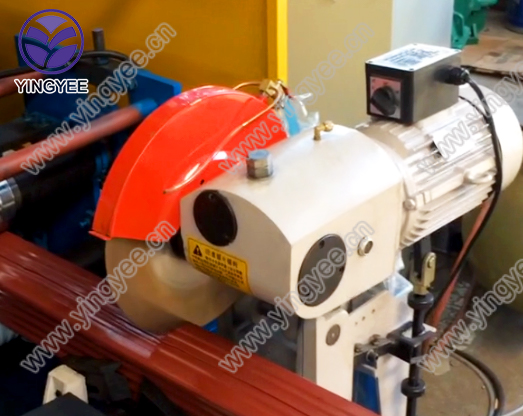

Gutter forming machines are specialized equipment designed to convert metal sheets, typically aluminum or steel, into seamless gutters. These machines utilize roll forming technology, which involves feeding a flat metal sheet into a series of rollers that progressively shape it into a finished gutter profile. This process not only maximizes material efficiency but also enhances the structural integrity of the gutters produced.

Advantages of Chinese Gutter Forming Machines

1. Cost-Effectiveness One of the primary reasons businesses look to China for gutter forming machines is the affordability. The cost of manufacturing in China is generally lower than in Western countries, allowing companies to acquire high-quality machinery at a fraction of the price.

2. Advanced Technology Chinese manufacturers have invested heavily in research and development to modernize production techniques. Many gutter forming machines now come equipped with computer numerical control (CNC) technology, enabling precise adjustments and automated production processes. This ensures uniformity and reduces human error, leading to higher-quality products.

3. Versatility Gutter forming machines from China can produce various gutter profiles, catering to specific market needs. Whether it’s K-style, half-round, or custom designs, these machines enable manufacturers to diversify their offerings and adapt to changing customer preferences.

4. High Production Capacity These machines are engineered for efficiency. High-speed production capabilities mean that manufacturers can fulfill larger orders in shorter timeframes, which is crucial in meeting construction deadlines.

5. Support and Service Many Chinese manufacturers offer comprehensive support services, including installation, training, and maintenance. This ensures that customers not only receive quality machinery but also the necessary expertise to operate it effectively.

Challenges and Considerations

While the advantages are numerous, there are also challenges associated with sourcing gutter forming machines from China. Quality control can sometimes be inconsistent, and potential buyers must conduct thorough research to find reputable manufacturers. Additionally, the language barrier and time zone differences can complicate communication and support.

Furthermore, there are geopolitical considerations that may impact international trade and logistics, emphasizing the need for businesses to remain agile in their sourcing strategies.

The Future of Gutter Forming Machines

Looking ahead, the demand for gutter forming machines is expected to grow. As urbanization continues and infrastructure development accelerates, the need for efficient gutter systems will become even more pronounced. Additionally, with increasing environmental awareness, there is a rising trend in using sustainable materials for gutter systems, prompting innovations within the industry.

In conclusion, Chinese gutter forming machines offer a promising solution for manufacturers seeking to optimize their production processes. With their cost-effectiveness, advanced technology, and versatility, these machines are poised to meet the growing needs of the construction industry. However, potential buyers must navigate challenges such as quality assurance and supplier reliability to fully leverage the advantages these machines provide. As the market evolves, staying informed and adaptable will be key for businesses looking to harness the potential of gutter forming technology.