Understanding the China Double Layer Roll Forming Machine

The China double layer roll forming machine is a cutting-edge piece of equipment that has revolutionized the metal forming industry. This machine is designed to produce two different profiles from two layers of metal sheets in a single pass, thus enhancing production efficiency and reducing material costs. With its robust construction and versatile applications, the double layer roll forming machine has become increasingly popular among manufacturers looking to optimize their production processes.

What is a Double Layer Roll Forming Machine?

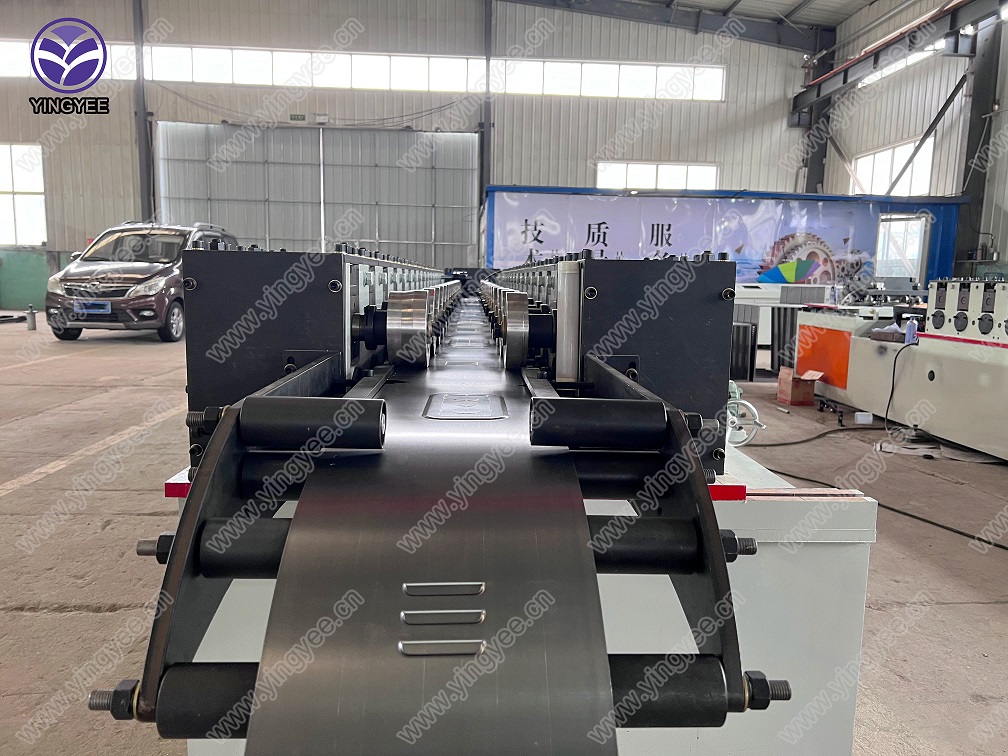

A double layer roll forming machine is a type of machinery used in the fabrication of metal products. It operates on the principle of roll forming, which involves feeding metal into a series of rolls that gradually shape the material to the desired profile. The innovation of the double-layer system allows for two distinct profiles to be produced simultaneously. This feature is particularly beneficial for manufacturers who require various product lines without the need for multiple machines.

Key Features and Benefits

1. Dual Profile Production One of the most significant advantages of a double layer roll forming machine is its ability to produce two profiles in one run. This feature maximizes production efficiency and minimizes downtime, as manufacturers do not need to switch between machines for different products.

2. Space Efficiency The compact design of double layer machines allows manufacturers to save valuable floor space in their facilities. Rather than dedicating large areas to multiple machines, a single unit can accommodate the production of various profiles.

3. Cost-Effectiveness By combining two production processes into one, manufacturers can significantly cut down on labor costs and energy consumption. This efficiency translates into lower production costs and improved profit margins.

4. Versatile Applications Double layer roll forming machines are used in a wide range of industries, including construction, agriculture, and automotive. They can produce various products such as roofing sheets, wall panels, and metal flooring, making them an invaluable asset for companies with diverse product lines.

5. High Precision Advanced technology and engineering design enable double layer roll forming machines to deliver high precision and consistent quality in product manufacturing. This reliability is crucial in industries where tolerances are critical for product performance.

6. Durability Built with sturdy materials and quality craftsmanship, these machines are designed for long-term use under demanding conditions. Regular maintenance and proper operation can significantly extend the operational lifespan of the equipment.

Selecting the Right Machine

When looking to invest in a double layer roll forming machine, manufacturers should consider several factors to ensure they select the right equipment for their needs. These factors include the types of profiles needed, the material specifications (such as thickness and type of metal), and the required production speed. Additionally, it's crucial to evaluate the reputation and service support offered by the machine manufacturers, as ongoing support is vital for maintaining high operational efficiency.

Conclusion

In summary, the China double layer roll forming machine stands as a highly efficient and versatile solution for metal fabrication needs. With its ability to produce two different profiles simultaneously, it enhances productivity, reduces costs, and saves space for manufacturers. As industries continue to evolve and demand higher efficiency in production processes, the double layer roll forming machine is likely to play an increasingly important role in shaping the future of manufacturing. By investing in this advanced technology, businesses can ensure they remain competitive in an ever-changing market.