Understanding the China CZU Purlin Machine An Essential Tool in Construction

In the ever-evolving construction industry, efficiency and precision are paramount. One of the standout innovations in this realm is the China CZU purlin machine. Designed specifically for the production of C and Z-shaped steel purlins, this machine plays a pivotal role in the structural framework of modern buildings. Understanding its features, benefits, and applications is essential for anyone involved in construction or manufacturing.

What is a CZU Purlin Machine?

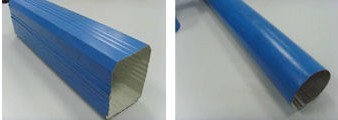

The CZU purlin machine is a metal forming machine that produces high-quality purlins used in various construction applications. Purlins are horizontal supports that help in reinforcing roofs and are essential for ensuring the stability and integrity of structures. The machine utilizes advanced technology to create precision-cut steel sections that meet various regulatory standards.

Key Features

One of the remarkable features of the CZU purlin machine is its versatility. It can produce both C and Z purlins, allowing manufacturers to cater to different project requirements with a single machine. The machine typically includes a decoiler, a feeding system, a forming unit, and a cutting mechanism, ensuring a streamlined production process. Most machines are also equipped with Computer Numerical Control (CNC) systems, which enhance accuracy and reduce human error.

Another significant feature is its high production capacity. Depending on the model, a CZU purlin machine can produce up to several dozen meters of purlins per minute. This efficiency allows for quicker turnaround times on construction projects and helps meet tight deadlines.

Advantages

The use of the CZU purlin machine offers several advantages. Firstly, it enhances the structural integrity of buildings. The precision with which purlins are manufactured ensures that they fit perfectly with other building components, which is crucial for overall stability. Secondly, the machine reduces labor costs. Automating the production process minimizes the need for manual labor, which can be both costly and time-consuming.

Additionally, the machine contributes to sustainability. With efficient material usage, it generates less waste compared to traditional manufacturing methods. As the construction industry increasingly focuses on environmentally friendly practices, this aspect of the CZU purlin machine cannot be overlooked.

Applications

CZ purlins are used in various applications, including warehouses, factories, and agricultural buildings. Their lightweight yet robust nature makes them ideal for structures requiring substantial support without unnecessary weight. Moreover, the adaptability of the C and Z profiles allows architects and engineers to design buildings that are not only functional but also aesthetically pleasing.

Conclusion

In conclusion, the China CZU purlin machine is a game-changer in the construction industry. With its ability to produce high-quality purlins efficiently, it meets the growing demands of modern architecture while ensuring structural integrity and sustainability. For construction businesses looking to enhance productivity and quality, investing in a CZU purlin machine is certainly a step in the right direction. As technology continues to advance, we can only anticipate further improvements in the capabilities and applications of such machines, shaping the future of construction.