Understanding the China Angle Roll Forming Machine

In the manufacturing sector, efficiency and precision are paramount. One of the most innovative machines that have emerged in recent years is the angle roll forming machine, particularly prominent in China. This equipment is designed to manipulate metal sheets into various shapes, specifically angles, which are essential in construction and industrial applications.

What is an Angle Roll Forming Machine?

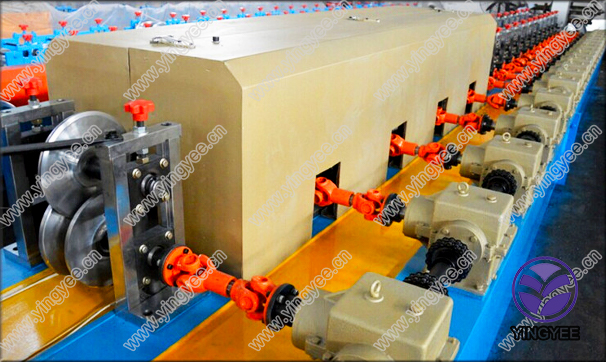

An angle roll forming machine is a piece of equipment used to cold-form metal sheets into specific shapes, such as L-angles, U-channels, and other custom profiles. The process involves feeding metal sheets through rolls that shape the material as it passes through. The design and capabilities of these machines can significantly vary, depending on the intended application and the type of material being used.

The Importance of Angle Roll Forming Machines

Angle roll forming machines play a critical role in several industries. They are particularly essential in the construction sector, where metal angles are used for framing, support structures, and various fixtures. The efficiency and precision offered by these machines minimize waste, thus translating to cost savings and increased productivity. In addition, they aid in achieving consistent quality, which is crucial for structural integrity.

Features of China Angle Roll Forming Machines

Chinese manufacturers have been at the forefront of producing advanced angle roll forming machines, incorporating the latest technology to enhance functionality

. Some of the standout features include1. High Efficiency These machines are engineered to produce a high volume of products in a shorter time frame, which is vital for meeting market demands.

2. Durability Made from high-quality materials, Chinese angle roll forming machines are built to withstand heavy use and have a longer lifespan.

3. Versatility They can handle various materials, including different grades of steel, aluminum, and other metals, allowing for a wide range of applications.

4. Customization Many manufacturers offer customized solutions, enabling clients to specify the configurations they require, thereby increasing flexibility in production.

5. User-friendly Interfaces Modern angle roll forming machines come equipped with advanced digital control systems, making them easier to operate and program for different profiles.

The Manufacturing Process

The operation of an angle roll forming machine starts with feeding a metal sheet into the machine. As the sheet passes through the rollers, it is gradually bent into the desired angle. The precision of this process is crucial, as any deviations can lead to structural weaknesses in the end product. Most machines are equipped with feedback systems that monitor the thickness and temperature of the metal to ensure consistent results.

The Market Trend

The demand for angle roll forming machines is on the rise, particularly in rapidly developing economies. China, being one of the largest producers of construction materials, has seen significant investments in this sector. The continuous development of infrastructure, including buildings, bridges, and roads, drives the need for efficient and reliable manufacturing systems like angle roll forming machines.

Conclusion

As the construction industry continues to grow, the importance of advanced manufacturing equipment such as angle roll forming machines will only increase. Chinese manufacturers are leading the way by offering innovative solutions that meet the diverse needs of the market. By investing in these machines, businesses can enhance their productivity, reduce waste, and maintain high standards of quality—key elements in today’s competitive industrial landscape. In conclusion, the angle roll forming machine not only represents a crucial technology in metal fabrication but also underscores the advancement in manufacturing capabilities that benefit various industries globally.