The Evolution and Significance of China Angle Roll Forming Machines

In recent years, the manufacturing landscape has undergone a transformative shift, with China emerging as a global leader in the production of advanced machinery. Among these innovations, the angle roll forming machine stands out as a significant development that caters to various industries across the globe. This article delves into the features, applications, and advantages of angle roll forming machines, emphasizing their impact on manufacturing processes.

Understanding Angle Roll Forming Machines

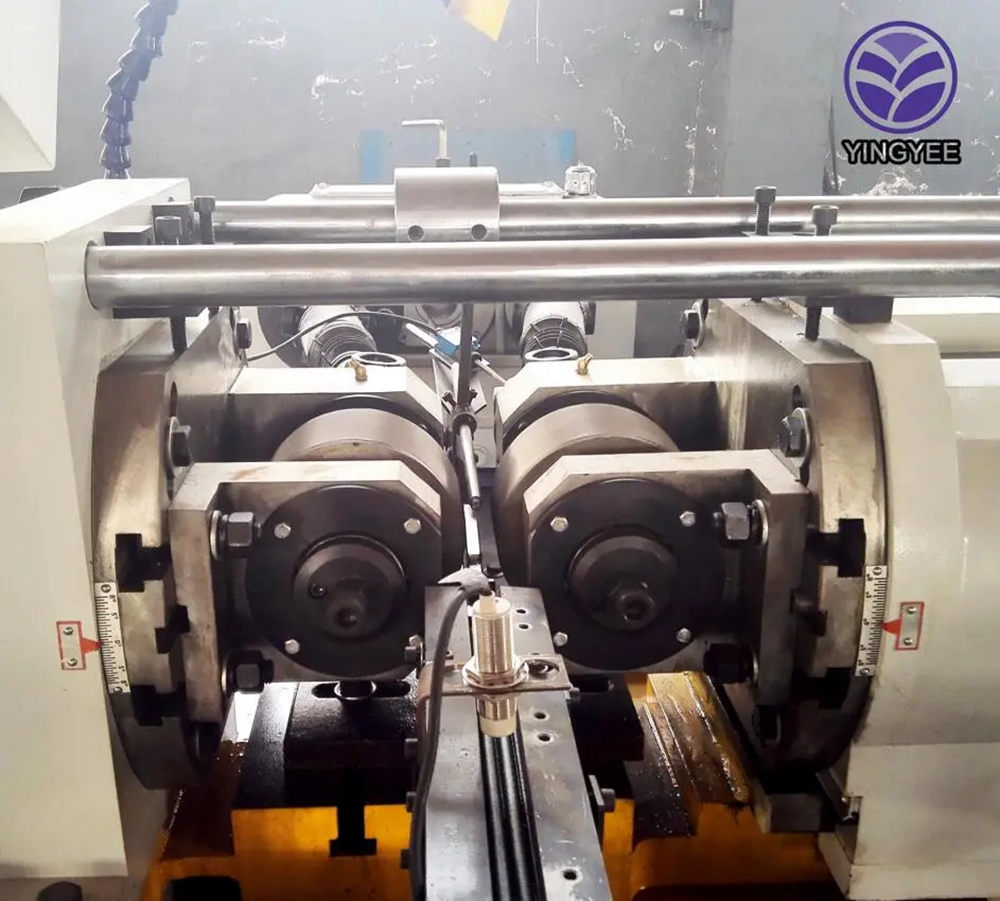

Angle roll forming machines are specialized equipment designed to create angular shapes from metal sheets or strips through a continuous bending process. The machine typically employs a set of rolls configured to shape the material as it passes through, enabling manufacturers to produce precise and consistent angles. This process is essential in the production of steel frames, brackets, and supports used in construction and automotive industries.

The primary components of an angle roll forming machine include a feed mechanism, forming rolls, and a control system. The feed mechanism ensures a steady and accurate supply of material, while the rolls are configured to achieve the desired profile. Modern machines often integrate advanced digital control systems, allowing operators to easily adjust parameters to accommodate different materials and specifications.

Applications Across Industries

Angle roll forming machines have a wide range of applications across several sectors. In the construction industry, they play a crucial role in producing structural components such as angles, channels, and tees that form the backbone of buildings and infrastructure. These components provide vital support and stability, highlighting the importance of precision and consistency in their production.

In the automotive industry, angle roll forming machines are utilized to manufacture parts such as brackets and frames that are critical for vehicle assembly. The machines enable manufacturers to produce lightweight yet robust components, contributing to overall vehicle efficiency and performance. Additionally, the versatility of these machines allows for the production of customized parts tailored to specific design requirements.

Another significant sector benefiting from angle roll forming technology is the furniture industry. Manufacturers use these machines to create various metal components for furniture, including frames, legs, and supports. The ability to design complex shapes and intricate profiles through roll forming enhances the aesthetic and functional aspects of furniture production.

Advantages of Angle Roll Forming Machines

The adoption of angle roll forming machines offers numerous advantages that make them appealing to manufacturers. One of the primary benefits is the ability to produce intricate shapes with high precision and repeatability. The continuous process minimizes material waste, making it a cost-effective solution for large-scale production.

Moreover, angle roll forming machines can handle a variety of materials, including mild steel, stainless steel, aluminum, and other metals. This versatility enables manufacturers to diversify their product offerings and meet varying customer demands. Additionally, the speed of the forming process allows for quicker turnaround times, enhancing overall productivity.

Another significant advantage is the reduced labor costs associated with automation. Modern angle roll forming machines often feature automated controls that streamline operations, reducing the need for manual intervention. This not only increases efficiency but also minimizes the risk of human error.

The Future of Angle Roll Forming Technology

As technology continues to advance, the future of angle roll forming machines appears promising. The integration of smart technologies, such as IoT and AI, is expected to enhance operational efficiency further. Manufacturers are beginning to explore connected machinery that can monitor performance, predict maintenance needs, and optimize production processes in real-time.

Additionally, as industries move towards sustainability, the ability of angle roll forming machines to utilize recyclable materials and produce minimal waste positions them favorably in the evolving market. Companies increasingly seek environmentally friendly solutions, and the roll forming process aligns with these goals.

Conclusion

In conclusion, angle roll forming machines represent a vital component of modern manufacturing in China and beyond. Their ability to produce complex metal shapes with precision and efficiency makes them indispensable in various industries, from construction to automotive. As technological advancements continue to reshape the manufacturing landscape, the angle roll forming machine is likely to evolve further, catering to the needs of an increasingly dynamic market. Manufacturers looking to enhance their production capabilities would do well to consider the advantages offered by this innovative machinery.