Channel Roll Forming Machine An Overview

Channel roll forming machines play a crucial role in the manufacturing sector, particularly in the production of channel steel sections used in various construction and industrial applications. These machines utilize a continuous process to shape metal sheets into channel profiles, ensuring efficiency and precision in creating uniform products.

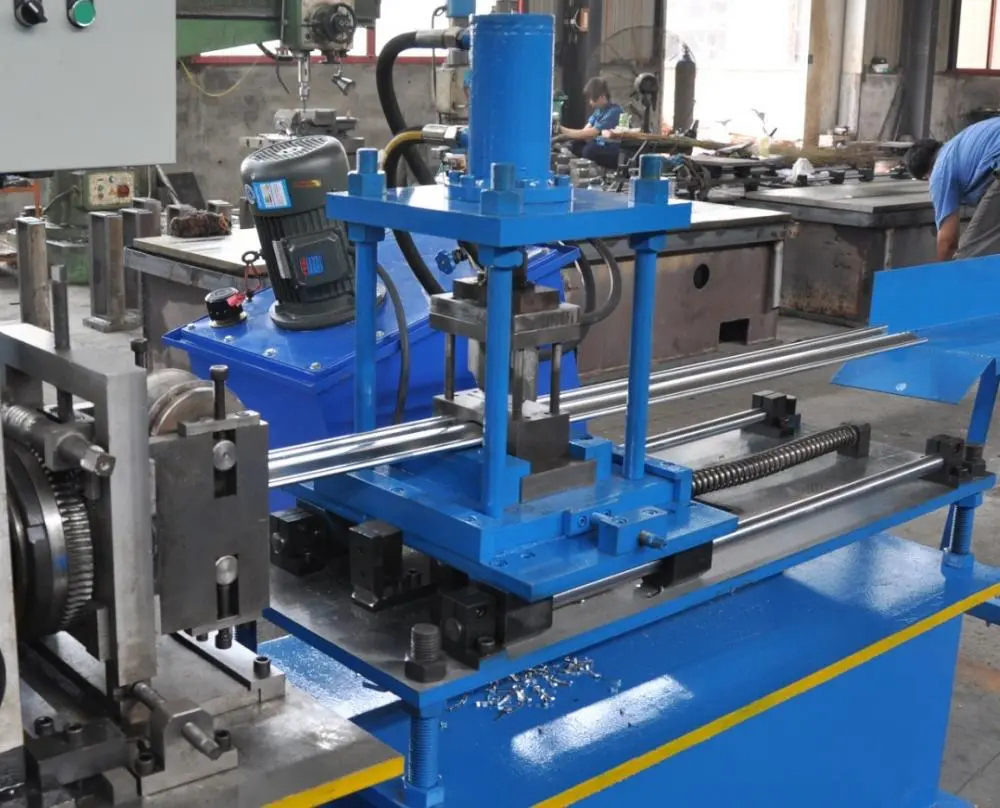

The basic operation of a channel roll forming machine involves feeding a flat steel strip into a series of rollers that gradually shape the metal into the desired channel cross-section. This process eliminates much of the manual labor and time associated with traditional fabrication methods, such as cutting and welding. Instead, the roll forming process allows for the creation of long lengths of channel shape products, which can be easily cut to specific sizes after the forming operation.

One of the significant advantages of channel roll forming machines is their ability to produce lightweight, yet strong structural components. The channel sections manufactured using this technology are often used for supporting structures, frames, and brackets in various applications, including warehouses, industrial buildings, and residential construction. The versatility of these machines allows manufacturers to customize the channel profiles and dimensions according to specific project requirements.

Modern roll forming machines are equipped with advanced technology to enhance their efficiency and output quality. Features such as programmable controls, automated feeding systems, and high-speed operation contribute to maintaining a high level of precision. Additionally, many machines offer adjustable roller settings, which allow operators to change the production profile with minimal downtime. This flexibility is essential for manufacturers who need to quickly adapt to market demands and customer specifications.

Moreover, the durability and reliability of channel roll forming machines make them a wise investment for metalworking companies. With regular maintenance and proper operation, these machines can operate for many years, offering consistent performance. The steel used in these processes is also recyclable, contributing to eco-friendly manufacturing practices that are becoming increasingly important in today’s industrial landscape.

As industries continue to evolve and demand more efficient production methods, the channel roll forming machine stands out as a vital piece of equipment in the manufacturing process. The ability to produce high-quality channel sections quickly and economically not only meets the needs of construction projects but also supports sustainable practices by minimizing waste and energy consumption.

In conclusion, channel roll forming machines represent an essential innovation in the metal fabrication industry. Their capacity to produce a wide range of products with precision and efficiency makes them invaluable to manufacturers. As technology advances, we can anticipate further improvements in the performance and capabilities of these machines, shaping the future of metal construction and enhancing the effectiveness of manufacturing processes across various sectors. Companies investing in channel roll forming technology are poised to benefit from increased productivity and competitiveness in an ever-demanding marketplace.