Overview of Channel Framing Roll Forming Machines

In the realm of metal manufacturing, channel framing roll forming machines have carved out a significant niche for themselves. These machines are engineered to produce channel sections with precision and efficiency, leading to their widespread adoption in various industries, including construction, automotive, and manufacturing. The roll forming process itself is a continuous bending operation where metal strip is shaped into channels and other profiles without the need for cutting or welding.

The Working Principle

The primary function of a channel framing roll forming machine is to transform flat metal sheets into desired channel shapes through a series of die sets. The process begins with a steel coil fed into the machine, which is then progressively shaped through a set of rollers. Each roller applies pressure to bend the metal gradually until it reaches the final configuration. This method is not only efficient but also minimizes waste, making it an eco-friendly choice for manufacturers.

Key Components

1. Feeding System The initial stage of the roll forming process involves feeding the raw material, typically a metal coil, through the machine. A precise feeding system ensures that the metal is fed in consistently, allowing for uniformity in the final product.

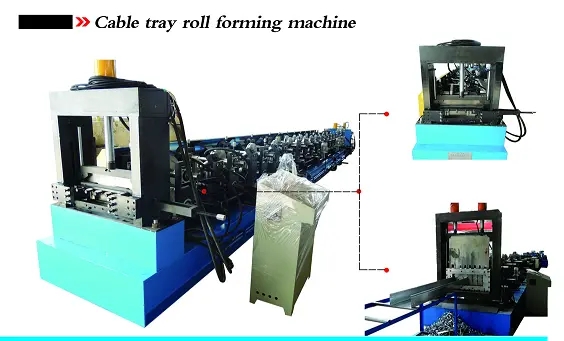

2. Rollers Arguably the core of the roll forming machine, the rollers are designed specifically to shape the metal into its final channel profile. The arrangement and design of these rollers can vary depending on the specific channel requirements.

3. Cutting Mechanism Once the channel has been formed, it is cut to the required length. This can be achieved either with a flying shear mechanism, which cuts the material while it’s in motion, or a stationary shear that operates when the material is momentarily halted.

4. Control System An advanced control system manages the operation of the roll forming machine, allowing for parameters such as speed, pressure, and cutting lengths to be adjusted. Many modern machines utilize programmable logic controllers (PLCs) for greater accuracy and reliability.

Advantages of Using Channel Framing Roll Forming Machines

1. High Precision Roll forming allows for tight tolerances and dimensional accuracy, making it suitable for industries where precision is paramount.

2. Material Efficiency The process generates minimal waste compared to traditional fabrication techniques. The continuous nature of roll forming maximizes the use of raw materials.

3. Versatility These machines can be easily adjusted to create various profiles or channels, catering to diverse customer needs. This flexibility is immensely beneficial, especially in industries requiring bespoke products.

4. Increased Production Speed Roll forming machines are capable of operating at high speeds, which significantly boosts production rates and enhances overall efficiency.

5. Durability and Strength The channels produced through roll forming are often stronger than those that are extruded or cut, making them suitable for structural applications.

Applications

Channel framing roll forming machines find applications in various sectors

- Construction The most common application is in structural framing for buildings, walls, and roofs. Channel sections are used extensively in creating support structures due to their strength.

- Automotive The automotive industry utilizes these machines to produce components such as chassis parts and reinforcement sections, where durability is critical.

- Furniture Manufacturing Channel profiles are also used in the production of frameworks for furniture, offering both aesthetic and functional benefits.

Conclusion

Channel framing roll forming machines represent a pinnacle of efficiency in metal manufacturing. Their ability to produce high-quality, precise channel sections quickly and with minimal waste has made them indispensable across various industries. As technology continues to evolve, it is likely that these machines will become even more advanced, incorporating features such as automation and smart technology, further enhancing their productivity and application scope. Investing in a channel framing roll forming machine may well be a strategic move for manufacturers looking to optimize their processes and reduce material costs while meeting the demands of modern engineering and construction.