The Versatility of Changeable C Purlin Roll Forming Machines

In the modern construction and manufacturing industries, the demand for efficient and adaptable machinery has never been higher

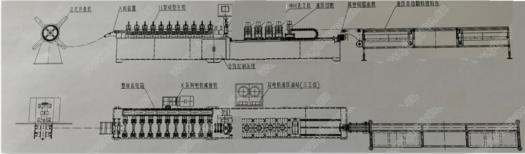

. Amongst these innovations, the changeable C purlin roll forming machine has emerged as a vital asset for companies seeking versatility and efficiency in their production processes.A C purlin is a structural element used in buildings, typically serving as a support for walls or roofing. Traditionally, manufacturing these components required distinct processes for each design or size, leading to increased costs and longer lead times. The advent of changeable C purlin roll forming machines revolutionizes this approach. These machines are designed to accommodate multiple sizes and configurations without the need for extensive retooling, streamlining production and enhancing flexibility.

One of the key features of changeable C purlin roll forming machines is their user-friendly design. Operators can easily adjust the machine settings to produce different profiles by simply changing the roll forming dies. This capability is particularly beneficial for businesses that deal with varying client requirements, as it allows for quick modifications to existing production lines to create purlins of various dimensions. Companies can effectively minimize downtime and optimize production schedules, resulting in significant operational cost savings.

In addition to flexibility, these machines are engineered for high efficiency. They utilize advanced technology to ensure precise cutting and shaping, which minimizes material waste. As raw material costs continue to rise, the ability to maximize material usage is crucial for maintaining profitability. Moreover, the streamlined process enabled by changeable C purlin roll forming machines also leads to shorter turnaround times, allowing manufacturers to fulfill orders faster and respond promptly to market demands.

Furthermore, the changeable C purlin roll forming machine is designed with durability in mind. Constructed from robust materials, these machines are built to withstand the rigors of continuous operation, reducing maintenance costs and downtime. Companies investing in such machines can expect a return on investment through increased productivity and decreased operational disruptions.

Environmental considerations are also becoming increasingly important in manufacturing. These machines are designed to be energy-efficient, contributing to lower operational costs and a smaller carbon footprint. By optimizing the production process, manufacturers can reduce waste and energy consumption, aligning with sustainable practices that are now a priority for many organizations.

In conclusion, changeable C purlin roll forming machines represent a significant advancement in the field of roll forming technology. Their ability to produce multiple profiles with minimal setup time, combined with their efficiency and durability, makes them an essential tool for manufacturers in the construction sector. As the industry continues to evolve, these versatile machines will undoubtedly play a crucial role in meeting the growing demands for customization and efficiency. Investing in a changeable C purlin roll forming machine not only enhances production capabilities but also positions companies for success in a competitive market.