When selecting a ceiling T-bar roll forming machine, several critical factors should be considered to optimize both performance and investment. These machines are integral to the construction industry, especially for creating the framework required in suspended ceiling installations. The decision-making process should focus on precision, reliability, and efficiency, which are paramount in ensuring a high-quality end product.

Firstly, evaluating the machine's design and manufacturing capabilities is essential. A high-quality ceiling T-bar roll forming machine should be engineered for precision to produce compatible components that fit seamlessly into a ceiling system. Assess whether the machine includes advanced features such as computerized numerical control (CNC), which enhances accuracy and repeatability during production. CNC systems facilitate automated adjustments and customization of different profiles without the need for manual recalibration, thus reducing downtime and material wastage.

In addition to precision, the material handling capacity of the machine must not be overlooked. It's crucial for the machine to process various materials, including galvanized steel and aluminum, which are commonly used in ceiling grid components, while maintaining the integrity of these materials throughout the forming process. Check for features that minimize surface scratches or structural compromise, which could affect the aesthetic and functional qualities of the finished product.

Furthermore, analyze the throughput speed of each model under consideration. In the fast-paced construction industry, time is often as valuable as quality. Thus, machines that offer quick changeover capabilities between different profile sizes and shapes can significantly impact productivity and operational efficiency. This flexibility will also allow manufacturers to respond swiftly to shifting market demands or project specifications, providing a competitive edge.

Another significant aspect to consider is the machine's long-term reliability and durability. Evaluating the build quality, warranties, and the availability of technical support and service can prevent costly downtime. Machines built from high-grade materials and equipped with robust components are typically more resistant to wear and tear, enhancing operational longevity. Opt for manufacturers known for their post-purchase support and strong service networks, which can be pivotal in maintaining continuous operations.

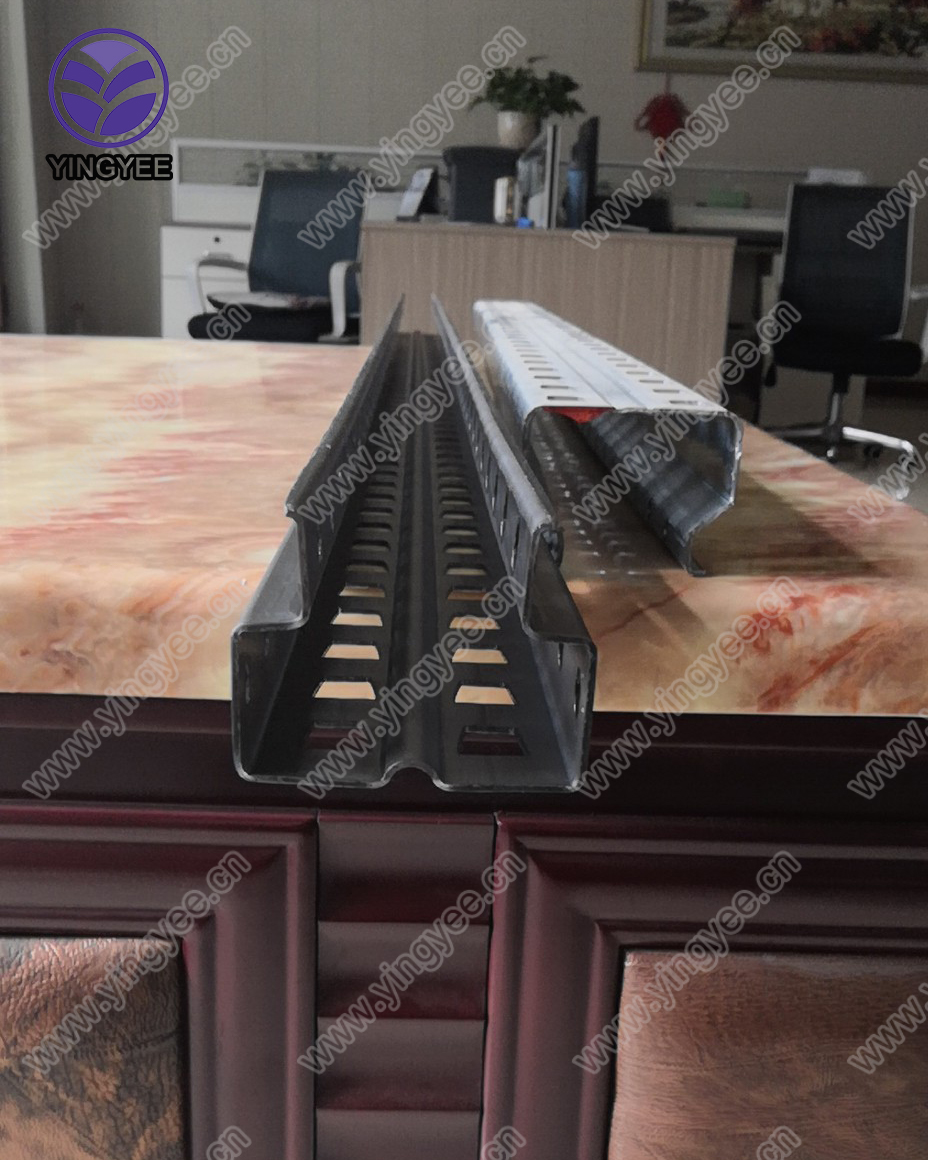

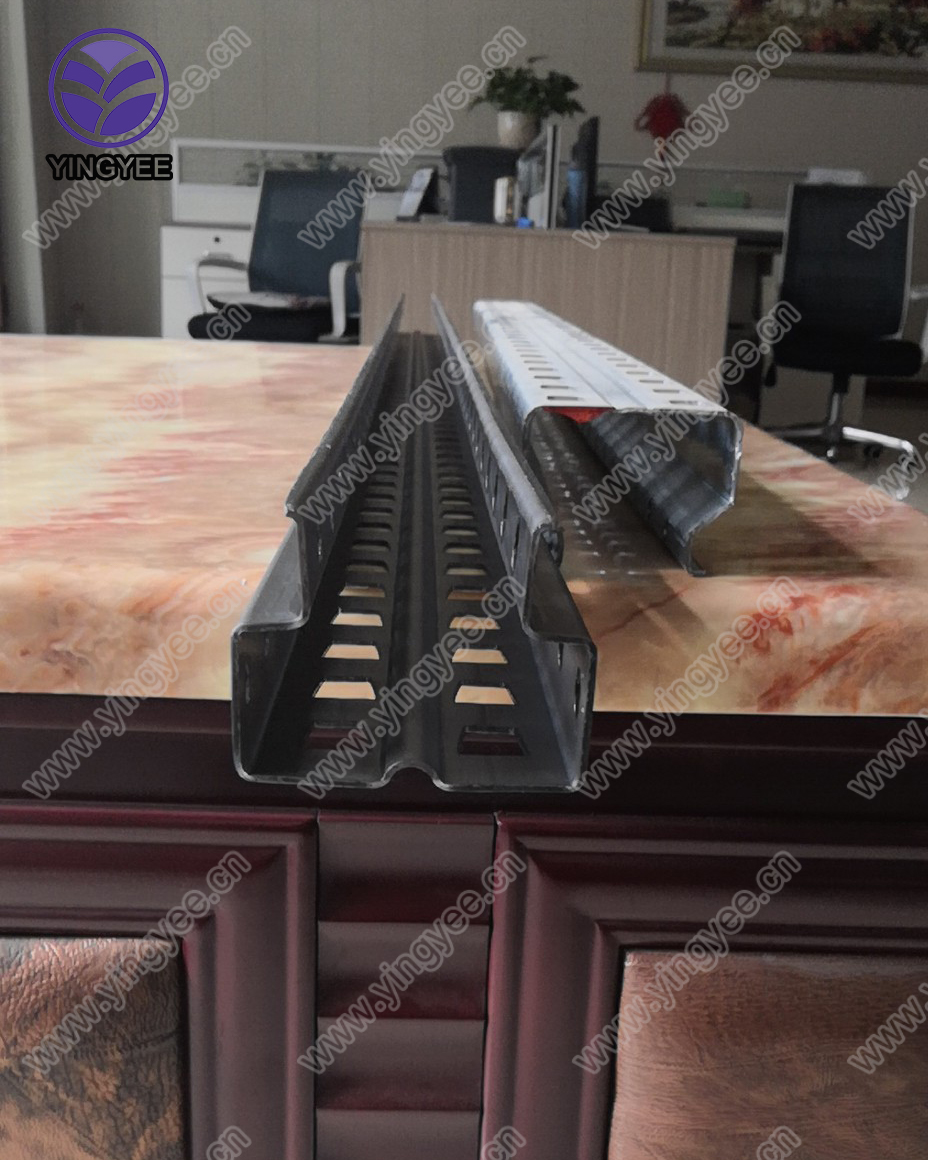

ceiling t bar roll forming machine

Beyond machine features, understanding the safety and compliance standards it adheres to is invaluable. Machines should comply with international safety regulations and environmental standards, ensuring a safe working environment and promoting sustainable practices. Review documentation and certifications to ensure compliance, as this could also impact your company's reputation and operational legality.

Additionally, prospective buyers should also consider the machine's ease of use. User-friendly interfaces, comprehensive training modules, and straightforward maintenance routines reduce the learning curve for operators and minimize the potential for user error. A machine that simplifies these aspects can contribute to maximizing productivity and reducing human resource costs.

Finally, industry reputation and reviews from existing users can be insightful. Engaging with industry forums or seeking testimonials about specific models or brands can provide real-world insights into the machine's performance and reliability. These firsthand accounts can corroborate manufacturer claims and offer practical advice beyond marketing materials.

In summary, selecting the right ceiling T-bar roll forming machine involves a holistic approach that balances precision, versatility, reliability, and operational efficiency. By scrutinizing machine design, material capabilities, throughput, safety features, and manufacturer support, businesses can make informed decisions that align with their production goals. This strategic investment in quality machinery not only ensures superior product outcomes but also strengthens a company's standing in the competitive construction market.