Ceiling T Bar Roll Forming Machine Revolutionizing Modern Construction

In the realm of modern construction and interior design, efficiency and precision are paramount. One of the innovative tools that have significantly contributed to this industry is the Ceiling T Bar Roll Forming Machine. This sophisticated machine stands out for its ability to produce T-shaped steel profiles used in ceiling systems. Understanding its operation, benefits, and applications can shed light on why it has become an indispensable asset in contemporary architecture.

What is a Ceiling T Bar Roll Forming Machine?

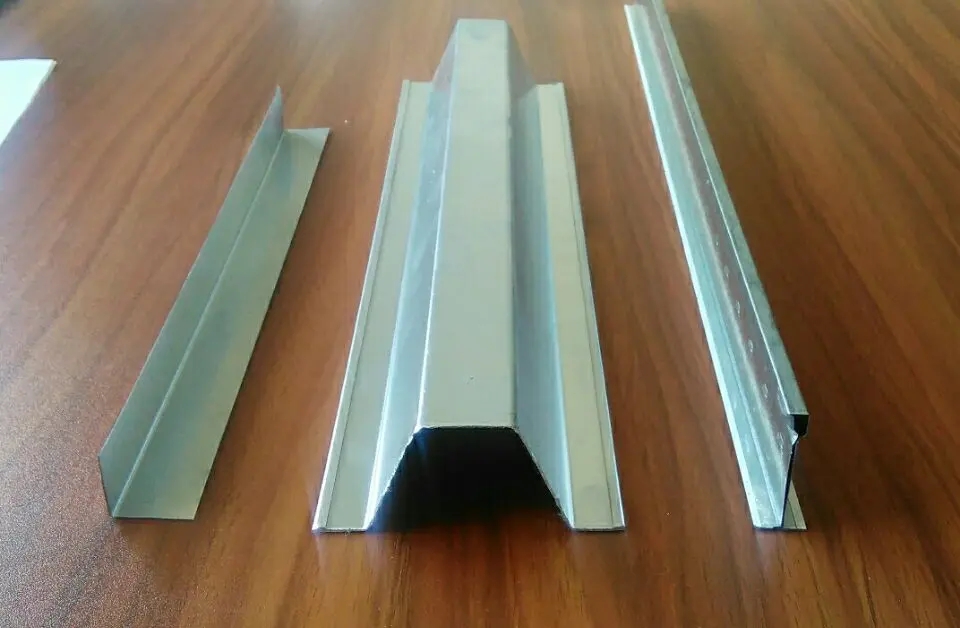

A Ceiling T Bar Roll Forming Machine is a specialized piece of equipment designed to continuously transform steel coils into T-shaped profiles. These profiles serve as main supports and cross supports for suspended ceiling grids, which are essential elements in both commercial and residential building projects. The machine operates on the principle of roll forming, where the metal is fed through a series of rollers that gradually shape it into the desired profile.

How Does It Work?

The process begins with feeding flat metal sheets or coils into the machine. The rollers, which are strategically designed and aligned, perform a series of bending operations to create the T-bar profile. The system is typically automated, allowing for consistent production rates and minimizing labor costs. After the roll forming process, the metal is cut to the specified lengths, ready for installation.

Advantages of Using a Ceiling T Bar Roll Forming Machine

1. Cost-Effectiveness By automating the production of T-bars, construction companies can significantly reduce labor costs and eliminate the need for extensive manual work. The high-speed production also means that large quantities of profiles can be manufactured in a short period, further enhancing profitability.

2. Precision and Consistency The machine guarantees high precision in the specifications of T bars, ensuring uniform quality in the products. This precision minimizes waste due to defects, providing a cost-effective solution in the long run.

3. Flexibility in Design With advancements in technology, modern Ceiling T Bar Roll Forming Machines can easily adjust to create various profiles and sizes. This flexibility allows manufacturers to cater to diverse architectural designs and client preferences.

4. Durability and Strength The T bars produced are typically made from galvanized steel, which offers excellent resistance to corrosion and structural integrity. This durability is crucial in preventing sagging or warping in suspended ceilings over time.

5. Ease of Installation The standardized dimension of T bars produced by these machines simplifies the installation process. A consistent product leads to quicker assembly times, which is a significant advantage for contractors facing tight schedules.

Applications in Construction

The primary application of Ceiling T Bar Roll Forming Machines is in the production of ceiling grid systems. These grids are widely used in commercial buildings, offices, hospitals, schools, and residential complexes. They provide not only aesthetic appeal but also functional benefits such as improved acoustics and easy access to utilities concealed above the ceilings.

Additionally, the T bars produced can be used in various other applications within the construction sector, including wall framing and supporting panels, showcasing the versatility of the roll-formed products.

Conclusion

The Ceiling T Bar Roll Forming Machine represents a significant advancement in construction technology. By enhancing the efficiency, precision, and quality of ceiling systems, this machine plays a crucial role in modern building practices. As the demand for innovative and cost-effective construction solutions continues to grow, the Ceiling T Bar Roll Forming Machine stands poised to meet the challenges of the future. Adopting such technology not only benefits manufacturers and contractors but ultimately results in better living and working environments for all.