Navigating the expansive world of industrial machinery, particularly the ceiling panel rolling machine, requires a blend of detailed understanding and practical knowledge. This piece aims to help businesses and professionals select and operate these machines effectively, focusing on their unique capabilities and practical applications.

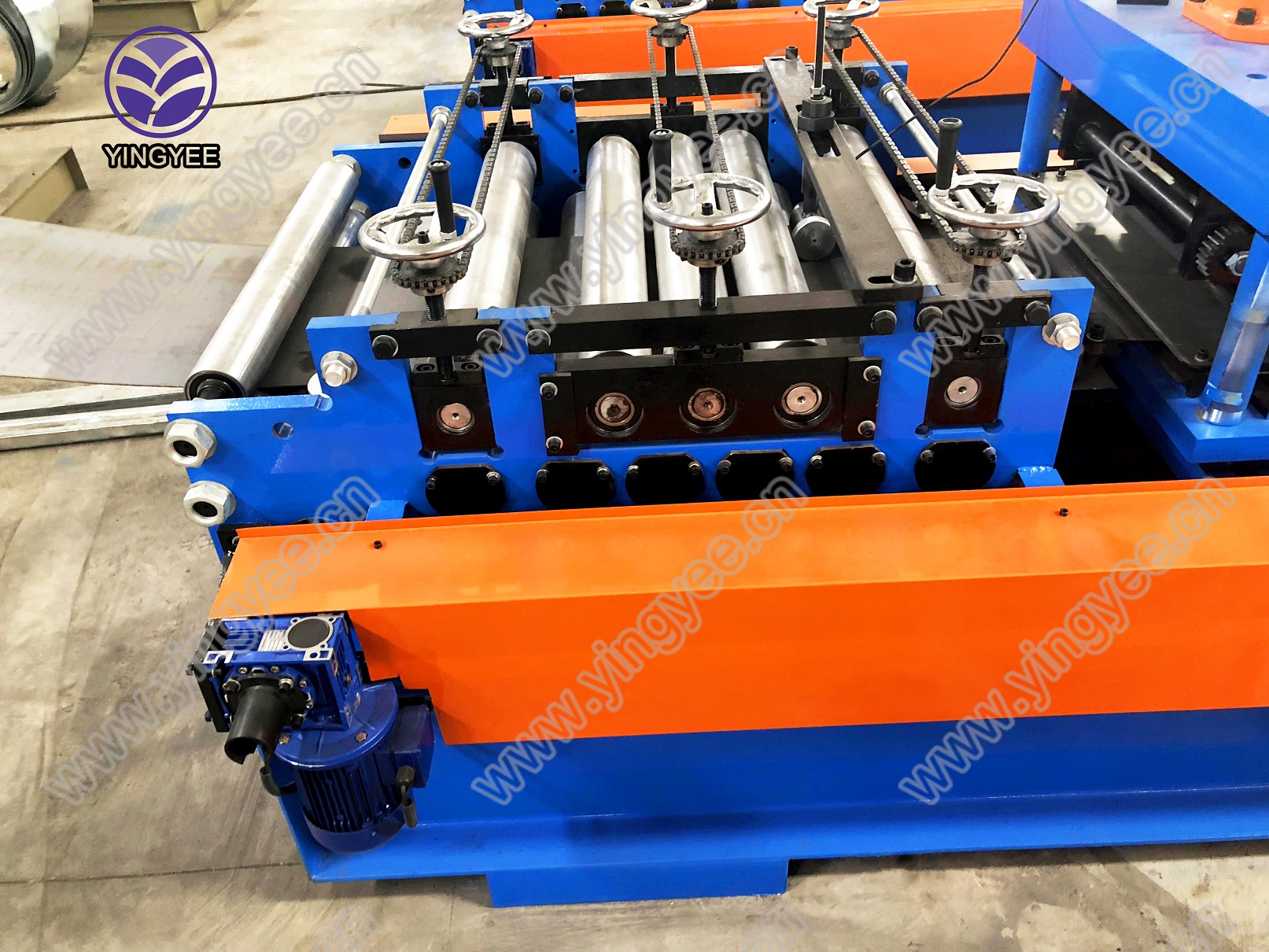

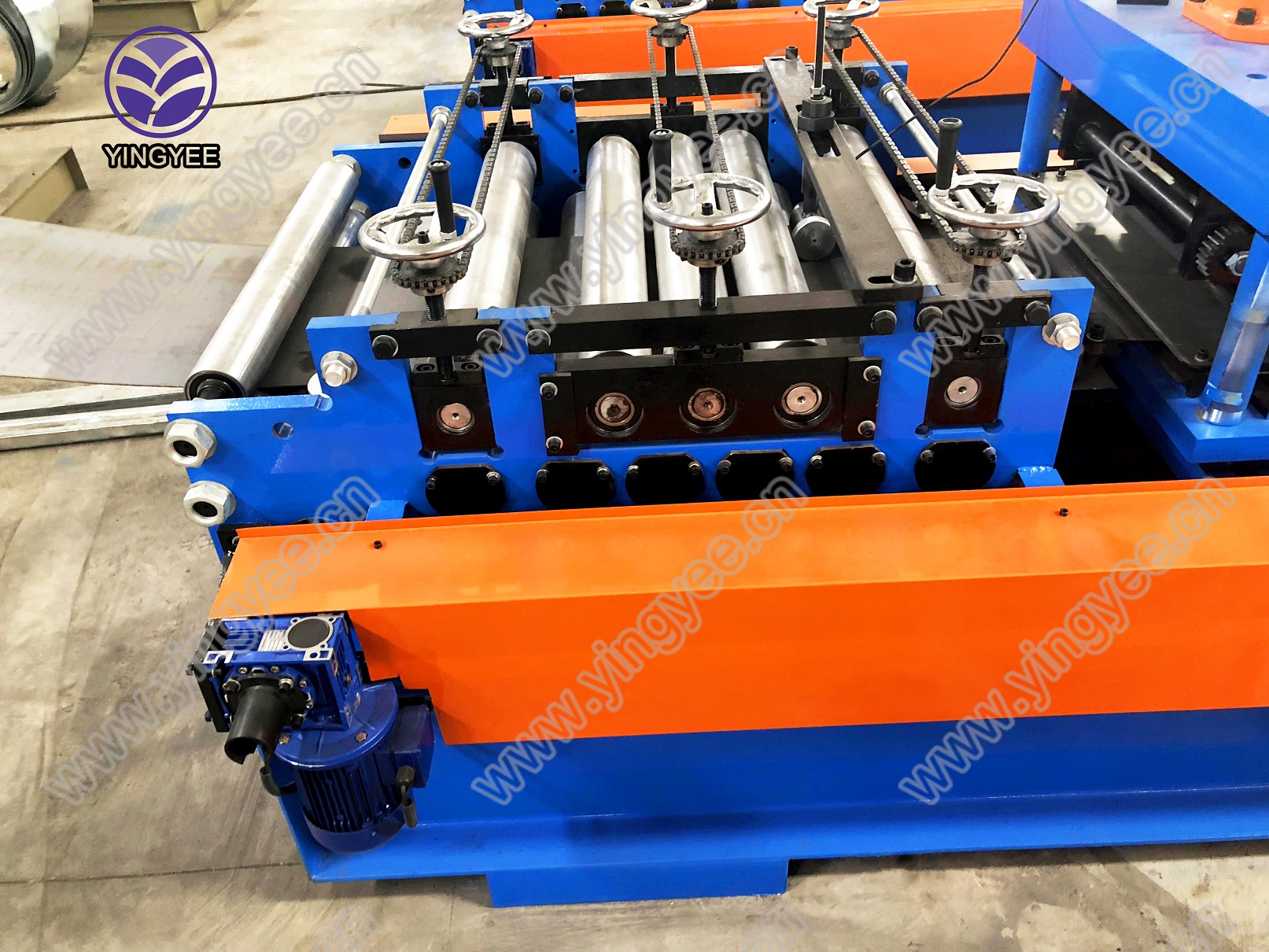

Ceiling panel rolling machines are pivotal in the construction and architectural industries. These machines transform flat metal sheets into intricately designed ceiling panels, revolutionizing ceilings in commercial and residential structures. The primary function is to enhance interior aesthetics while fulfilling structural requirements. Such machines ensure that ceiling panels are produced with precision, maintaining uniformity in every batch, thus saving time and reducing waste in production processes.

The experience observed by operators across different manufacturing plants significantly underscores the importance of choosing the right ceiling panel rolling machine. Advanced machines today come equipped with user-friendly interfaces and programmable systems that ensure ease of operation even for those with limited technical know-how. For instance, some manufacturers have integrated smart technology into these machines for real-time monitoring and adjustments, which enhances not only the efficiency but also the quality of the panels produced.

From the perspective of expertise, utilizing a ceiling panel rolling machine requires ongoing training and familiarization with technological advancements. Many companies have incorporated digital twins of their machinery in training modules, simulating real-life operations and potential issues that could arise during production. This innovation allows operators and technicians to develop proficiency in troubleshooting without disrupting actual machine operations, maintaining a steady flow of production and minimizing downtime.

ceiling panel rolling machine

Authority in the realm of ceiling panel rolling machines comes from both historical reliability and adaptability to new materials and designs. Leading manufacturers boast a long-standing reputation forged on decades of delivering durable machinery that can handle diverse types of metal and intricate ceiling designs. Their machines are rigorously tested under various conditions to ensure compliance with industry standards and regulations, reinforcing their status as go-to solutions in the market.

Trustworthiness is intricately linked with post-purchase services offered by machine manufacturers. Companies that provide comprehensive warranties, alongside regular maintenance checks, build a solid relationship with their clients. These services ensure longevity and efficient performance of the machines. Additionally, staying abreast of customer feedback and incorporating it into future machine upgrades and designs plays a crucial part in maintaining trust. Users consistently report higher satisfaction when manufacturers respond promptly to concerns and demonstrate a commitment to continual improvement.

In the dynamic landscape of construction technology, the ceiling panel rolling machine stands out as a transformative tool that bridges traditional craftsmanship with modern efficiency. Whether it's a small-scale operation setting out to enhance local architecture, or a corporation aiming to meet the demands of grand-scale projects, choosing the right machine can significantly impact both the quality and pace of production.

In conclusion, selecting the ideal ceiling panel rolling machine involves a careful consideration of its technical capabilities, the level of expertise required for operation, and the reliability of the manufacturer. With a rapidly advancing field and increasing demands for innovative ceiling designs, staying informed about the latest technologies and best practices is essential. As industry needs continue to evolve, these machines will remain central to delivering on expectations of design, durability, and functionality. By investing in a trusted ceiling panel rolling machine, businesses not only optimize their production processes but also position themselves as leaders in the world of architectural innovation.