The Ceiling Panel Rolling Machine Revolutionizing Construction

In the ever-evolving world of construction and interior design, innovation plays a critical role in shaping efficiency and quality. Among the numerous advancements, the ceiling panel rolling machine stands out as a groundbreaking solution that has transformed the way ceiling materials are produced. This article delves into the purpose, functionality, and advantages of ceiling panel rolling machines, shedding light on their significance in modern construction.

What is a Ceiling Panel Rolling Machine?

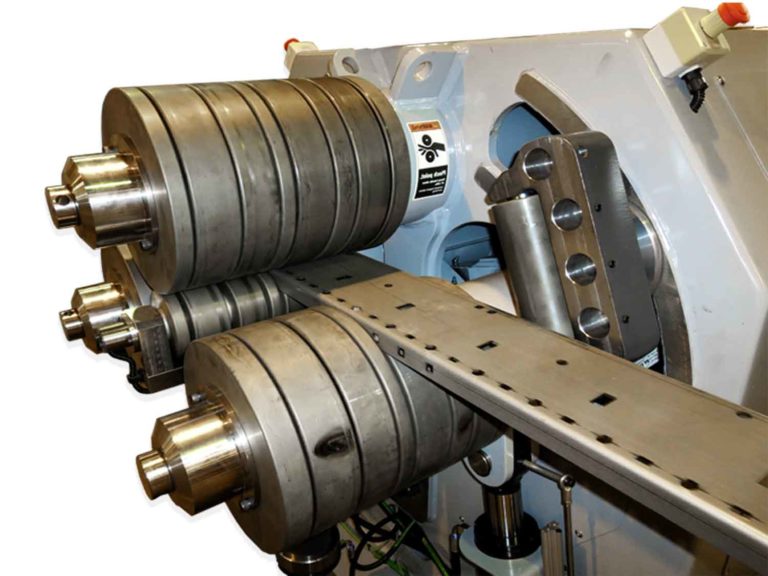

A ceiling panel rolling machine is a specialized piece of equipment designed to manufacture ceiling panels in various shapes and sizes. Utilizing advanced technology, this machine produces panels that are not only aesthetically pleasing but also functional and durable. The process involves taking long strips of material, commonly metal or PVC, and shaping them into finished ceiling panels through a series of rollers that mold and cut the material according to specified dimensions.

Functionality of the Machine

The operation of a ceiling panel rolling machine typically begins with the entry of raw materials into the machine. The material is fed through a series of rollers, where it is shaped and formed into the desired profile. The complexity of designs can vary, allowing manufacturers to create intricate patterns or simple, clean lines. Many models come equipped with programmable controls, enabling operators to set dimensions and specifications easily.

Once the roll forming process is complete, the panels are cut to length, ensuring that each piece produced meets the exact requirements of the project. Additional features such as punching holes or adding insulation can also be incorporated during the manufacturing process, further enhancing the quality and functionality of the final product.

Advantages of Using Ceiling Panel Rolling Machines

1. Efficiency and Speed One of the significant benefits of using ceiling panel rolling machines is the speed at which they operate. Traditional methods of ceiling panel production can be time-consuming and labor-intensive. In contrast, a rolling machine can produce large quantities of panels in a fraction of the time, significantly boosting productivity.

2. Cost-Effectiveness By automating the production process, ceiling panel rolling machines reduce labor costs and minimize waste. The precise cutting and shaping capabilities of these machines ensure that materials are used efficiently, contributing to overall cost savings for manufacturers.

3. High Precision and Consistency Ceiling panel rolling machines are renowned for their ability to produce panels with high precision. Consistency in size and shape is crucial, especially in large-scale construction projects. These machines minimize human error, ensuring that every panel meets stringent quality standards.

4. Customization Modern rolling machines allow for a high degree of customization, enabling manufacturers to cater to specific design requirements. Whether it’s a unique profile or a specific finish, the versatility of these machines can accommodate a range of styles and preferences.

5. Enhanced Quality Panels produced by rolling machines often exhibit superior quality compared to those made using traditional methods. The uniformity and durability of the finished product are substantial, leading to longer-lasting ceilings that can withstand various environmental factors.

Applications in Construction

Ceiling panel rolling machines find their applications in various sectors of construction, including residential, commercial, and industrial buildings. In residential settings, they are used to produce attractive ceiling designs that enhance aesthetic appeal. In commercial buildings, such panels contribute to functional and soundproofing qualities, essential for office environments. Moreover, the industrial sector often utilizes ceiling panels for practicality, focusing on durability and maintenance.

Conclusion

The ceiling panel rolling machine represents a significant advancement in construction technology. By combining efficiency, precision, and versatility, these machines have revolutionized the production of ceiling panels, setting new standards in quality and design. As the construction industry continues to evolve, embracing innovations like the ceiling panel rolling machine will be crucial in meeting the growing demands for speed, cost-effectiveness, and superior craftsmanship. This transformation not only benefits manufacturers but also enhances the overall quality of construction projects, paving the way for more sustainable and aesthetically pleasing environments.