The Ceiling Channel Roll Forming Machine A Comprehensive Guide

In the world of construction and interior design, the use of high-quality building materials is paramount. One such material that has gained traction is the ceiling channel, used extensively in the installation of suspended ceilings, drywall systems, and various decorative elements. The production of these ceiling channels is made efficient and precise through the use of advanced machinery known as the ceiling channel roll forming machine. This article delves into the functionality, benefits, and applications of this crucial piece of equipment.

Understanding Roll Forming

Roll forming is a manufacturing process that involves the continuous bending of a strip of metal (often steel or aluminum) into a desired cross-sectional profile. The metal is passed through a series of rolls set to achieve the desired shape. This process is highly efficient, particularly for producing long lengths of material, and is known for its ability to maintain consistent quality and precision throughout production.

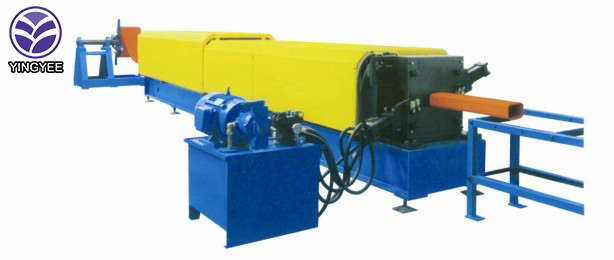

Key Components of a Ceiling Channel Roll Forming Machine

A typical ceiling channel roll forming machine consists of several key components

1. Uncoiler This component feeds the metal strips into the machine. The uncoiler unwinds the coils of metal, allowing for continuous feeding into the forming section.

2. Feeding System A precise feeding mechanism ensures that the metal strip is fed at the correct speed and position, which is vital for achieving uniformity.

3. Roll Forming Stations These stations contain multiple sets of rollers that progressively shape the metal strip into the desired ceiling channel profile. Each station performs a specific function, gradually forming the material with high accuracy.

4. Cutting Unit Once the ceiling channel has been formed, it needs to be cut to specific lengths. The cutting unit, often equipped with hydraulic or mechanical cutting tools, ensures clean cuts without damaging the material.

5. Control System Modern roll forming machines are equipped with advanced control systems that allow operators to monitor and adjust various parameters, such as speed, temperature, and pressure. This enhances the overall efficiency and consistency of the production process.

Benefits of Using a Ceiling Channel Roll Forming Machine

Utilizing a ceiling channel roll forming machine offers several advantages that make it an essential tool in modern construction

.

1. Efficiency Roll forming is a continuous process, meaning that large volumes of ceiling channels can be produced in a relatively short amount of time. This is particularly beneficial for large construction projects that require a significant amount of material.

2. Cost-Effectiveness The high-speed operation and reduced material wastage associated with roll forming translate into lower production costs. In addition, the precision of the machine minimizes the need for secondary operations, further reducing expenses.

3. Consistency and Precision The machine’s ability to maintain tight tolerances ensures that every piece produced is uniform in size and shape, which is crucial for applications that require exact specifications.

4. Versatility Many ceiling channel roll forming machines can be customized to produce different profiles and sizes, catering to varied design requirements in the construction industry.

5. Automation Capabilities With the integration of advanced technology, these machines can be automated to streamline operations, reduce labor costs, and enhance safety on the job site.

Applications of Ceiling Channels

Ceiling channels produced by roll forming machines have diverse applications in construction

1. Suspended Ceiling Systems Ceiling channels serve as the structural framework for hanging ceiling tiles, providing support and stability.

2. Drywall Installation They are essential components in the framing of drywall systems, ensuring that walls and ceilings are securely fastened.

3. Decorative Elements In modern interior design, ceiling channels can be used to create intricate patterns and features that enhance aesthetic appeal.

4. Industrial and Commercial Settings Ceiling channels are widely used in warehouses, shopping malls, and office buildings where overhead systems like HVAC and lighting need a reliable structure.

Conclusion

The ceiling channel roll forming machine is a vital piece of equipment that plays a significant role in the construction industry. Its efficiency, precision, and versatility make it an invaluable tool for producing high-quality building materials. As construction demands continue to evolve, so too will the technologies associated with roll forming, paving the way for even more innovative solutions in building design and construction practices. With the right machinery, manufacturers can not only meet but exceed the expectations of a dynamic industry, ensuring structural integrity and aesthetic excellence for projects across the globe.