Ceiling Bar Roll Forming Machine Revolutionizing Modern Architecture

In the ever-evolving world of modern construction, innovation plays a key role in enhancing efficiency and quality. Among the various technologies that have emerged, the ceiling bar roll forming machine stands out as a significant advancement. This machine not only streamlines the production of ceiling bars but also ensures the creation of high-quality components essential for a range of architectural applications.

What is a Ceiling Bar Roll Forming Machine?

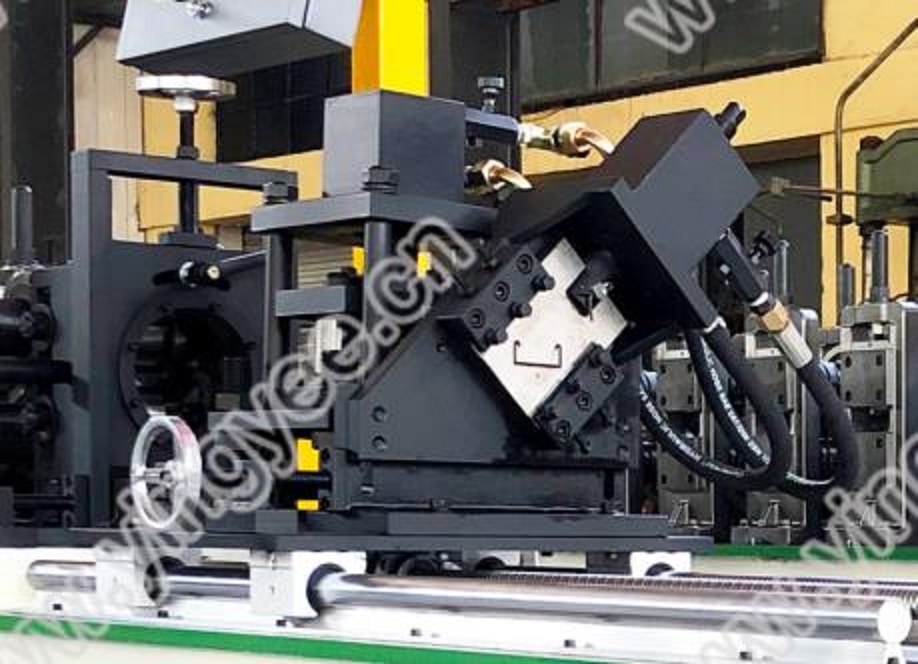

A ceiling bar roll forming machine is a sophisticated piece of equipment designed to produce metal ceiling bars in various profiles and sizes. The process begins with a flat strip of metal, usually steel or aluminum, which is fed into the machine. Through a series of rollers configured in a specific arrangement, the flat metal strip is gradually shaped and formed into the desired ceiling bar profile. The entire process is continuous, allowing for high-volume production without sacrificing precision.

The Benefits of Using a Ceiling Bar Roll Forming Machine

1. Efficiency and Speed One of the most significant advantages of using a ceiling bar roll forming machine is its speed. Compared to traditional manufacturing methods, roll forming can produce components rapidly, significantly reducing lead times.

2. Quality Control With the ability to produce uniformed and precise ceiling bars, this machine is crucial for maintaining high-quality standards in construction. The consistent dimensions and strength of the bars produced ensure they meet rigorous industry standards.

3. Cost-Effectiveness While the initial investment in a roll forming machine may be considerable, the long-term savings achieved through reduced labor costs and minimized material waste make it a financially viable option for manufacturers. Additionally, as production increases, the cost per unit decreases.

4. Versatility Ceiling bar roll forming machines can be adapted to produce a variety of profiles, making them highly versatile. This adaptability caters to the needs of different projects and allows manufacturers to diversify their product offerings.

5. Automation Many modern roll forming machines come equipped with automation features, reducing the need for manual intervention. This technology not only speeds up production but also minimizes human error, leading to a more efficient manufacturing process.

Applications in Modern Construction

Ceiling bars produced by roll forming machines find numerous applications in the construction industry. They are primarily used in suspended ceilings, which are a popular choice for commercial buildings, offices, and residential spaces. The lightweight yet sturdy nature of these bars supports a variety of ceiling tiles and panels, offering both aesthetic appeal and functional benefits such as sound insulation and thermal resistance.

Moreover, the use of ceiling bars in grid systems enables easy installation and maintenance of lighting fixtures, HVAC systems, and acoustic treatments. This adaptability makes them a preferred choice for architects and builders, thus ensuring a seamless integration into various design schemes.

Future Trends in Roll Forming Technology

As technology continues to advance, the future of the ceiling bar roll forming machine looks promising. Innovations such as Industry 4.0 integration and smart manufacturing will likely enhance operational efficiency further. The incorporation of advanced monitoring systems will allow manufacturers to optimize their processes in real-time, ensuring maximum productivity and minimal waste.

Additionally, growing environmental concerns are pushing the industry toward more sustainable practices. Future roll forming machines may focus on utilizing recycled materials and energy-efficient production methods, thereby contributing to greener building practices.

Conclusion

In conclusion, the ceiling bar roll forming machine represents a pivotal development in the construction industry. Its ability to produce high-quality, precise components quickly and cost-effectively makes it an indispensable tool for modern architects and builders. As technology advances and sustainability becomes increasingly essential, the role of these machines will continue to grow, further shaping the landscape of contemporary architecture.