The Importance of Ceiling Bar Roll Forming Machines in Modern Construction

In the construction industry, efficiency, precision, and quality are paramount. One piece of machinery that has revolutionized the way ceiling bars are produced is the ceiling bar roll forming machine. This innovative equipment has become increasingly vital due to its ability to manufacture ceiling support structures that are both durable and lightweight, which is essential for modern architectural designs.

Understanding Ceiling Bar Roll Forming Machines

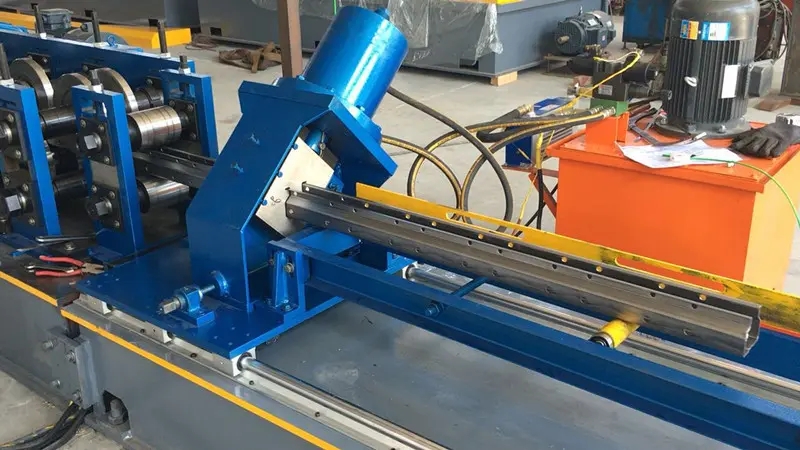

A ceiling bar roll forming machine is a piece of equipment designed to create ceiling bars from metal strips or coils. These bars serve as structural supports for suspended ceilings or as decorative elements in various architectural settings. The machine works by passing the metal strips through a series of rollers that gradually shape them into the desired profile. The process is often automated, allowing for high-speed production with minimal labor input.

The versatility of ceiling bar roll forming machines makes them suitable for a variety of applications. They can produce different shapes and sizes of ceiling bars, accommodating various design requirements. This adaptability is crucial for contractors and builders who need to meet specific project demands while ensuring that materials are delivered promptly.

Key Features and Benefits

1. Efficiency One of the primary advantages of using ceiling bar roll forming machines is their ability to produce materials quickly and efficiently. Traditional methods of manufacturing ceiling bars can be time-consuming and labor-intensive. However, with automated roll forming machines, manufacturers can produce large quantities of ceiling bars in a fraction of the time.

2. Precision The roll forming process is highly precise, ensuring that each ceiling bar is manufactured to exact specifications. This precision minimizes waste and reduces the likelihood of errors during installation. The ability to maintain consistent quality throughout production is a significant advantage, as it contributes to the overall integrity of the construction project.

3. Material Flexibility Ceiling bar roll forming machines can work with various materials, including steel, aluminum, and other alloys. This flexibility allows manufacturers to select the most suitable materials for their specific applications, ensuring optimal performance and durability.

4. Cost-Effectiveness While the initial investment in a ceiling bar roll forming machine may be significant, the long-term savings are substantial. The combination of reduced labor costs, minimized material waste, and increased production speed contributes to a lower overall cost of manufacturing.

5. Customization Many modern ceiling bar roll forming machines come equipped with advanced technology that enables easy customization of designs. Producers can modify the machine settings to create unique profiles based on specific architectural needs, which adds tremendous value for clients looking for tailored solutions.

The Role of Technology in Evolution

The ceiling bar roll forming industry has also benefited from advancements in technology. Digital controls and automated systems allow for greater precision and adaptability, enabling manufacturers to quickly switch between different products or specifications. Additionally, improvements in CAD (Computer-Aided Design) software facilitate the design process, allowing engineers to create detailed models before production begins.

Moreover, the integration of robotics and automation in the manufacturing process enhances productivity while minimizing human error. This technological evolution ensures that ceiling bar roll forming machines are not just a staple in construction, but also a key component in the industry's future.

Conclusion

In conclusion, ceiling bar roll forming machines play a crucial role in modern construction by enhancing efficiency, precision, and customization in the production of ceiling bars. As the demand for innovative architectural designs continues to grow, so too does the importance of this machinery in meeting those demands. By leveraging the capabilities of ceiling bar roll forming machines, builders and contractors can ensure that they deliver high-quality, durable, and aesthetically pleasing results to their clients. As the industry evolves, these machines are likely to become even more sophisticated, further solidifying their integral role in construction.