C Channel Steel Roll Forming Machine A Comprehensive Overview

In the world of metal fabrication, efficiency, precision, and versatility are paramount. One of the key innovations that have transformed this sector is the C channel steel roll forming machine. This specialized equipment is designed for the production of C-shaped steel channels, which are essential components in various construction and manufacturing applications. In this article, we will explore the functionality, benefits, and market relevance of C channel steel roll forming machines.

What is a C Channel Steel Roll Forming Machine?

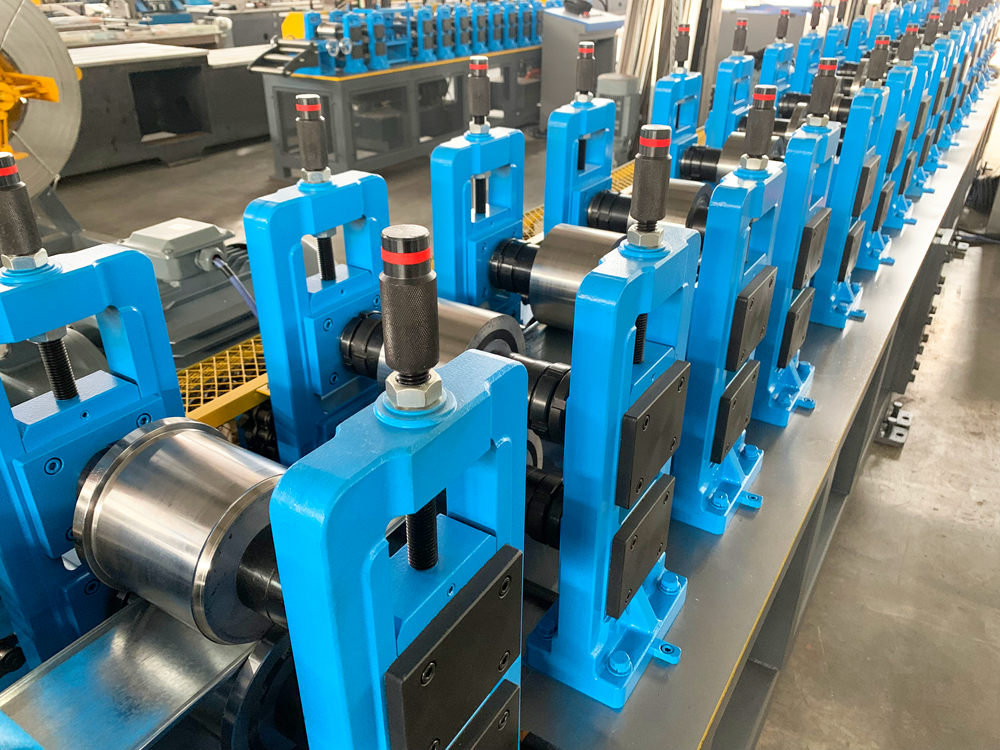

A C channel steel roll forming machine is a type of industrial machinery that continuously transforms flat steel coils into C-shaped profiles through a series of mechanical processes. These machines operate by feeding steel coils into a set of rollers, which progressively bend and shape the material into the desired dimensions. The final product, the C channel, possesses a distinctive, channel-like geometry that provides structural support and is widely used in building frames, racks, and various infrastructure projects.

Key Features of C Channel Steel Roll Forming Machines

1. Automated Production Modern C channel roll forming machines are equipped with automation features that enhance productivity. They typically include computerized controls that allow for easy adjustments, ensuring consistent quality across batches.

2. Versatility Many machines are designed to produce various profiles with minimal setup changes. This flexibility is crucial for manufacturers who need to switch between different specifications based on client demands.

3. Precision Engineering High-quality C channel steel roll forming machines utilize advanced engineering techniques and materials, ensuring that the resulting profiles meet strict tolerances. Accurate dimensions are essential for ensuring the structural integrity of the final construction.

4. Robust Build These machines are built to withstand heavy-duty usage. Their robust construction ensures longevity and reliability, critical factors in high-volume production environments.

5. Easy Maintenance Many modern machines are designed with maintenance in mind, featuring accessible components that simplify routine checks and repairs, thereby reducing downtime.

Benefits of Using a C Channel Steel Roll Forming Machine

1. Cost Efficiency By automating the roll forming process, manufacturers can significantly reduce labor costs while increasing production speed. The ability to produce large quantities of C channels quickly translates into better pricing for clients.

2. High Quality and Consistency Automated systems minimize human error, resulting in high-quality products with uniform dimensions. This consistency is crucial in industries where structural stability is paramount.

3. Customization Options The ability to adjust the machine settings allows for the production of custom dimensions based on specific project requirements, catering to diverse market needs.

4. Reduced Waste The precise nature of roll forming leads to less material waste compared to other manufacturing processes. Efficient use of raw materials contributes to sustainability efforts within the industry.

5. Scalability As business needs grow, manufacturers can scale their operations without significant capital investment. The flexibility of C channel steel roll forming machines allows for easily adapting to increased production demands.

Market Applications

C channel steel profiles produced by roll forming machines find applications in various sectors, including construction, automotive, HVAC systems, and furniture manufacturing. Their strength and versatility make them suitable for use as structural support beams, in shelving systems, and much more. With the growth of the construction industry globally, the demand for C channel profiles continues to rise, making the roll forming machines an essential investment for manufacturers aiming to capture this expanding market.

Conclusion

The C channel steel roll forming machine represents a significant advancement in metal fabrication technology. With its ability to produce high-quality, precision-engineered C channels efficiently, it meets the demands of modern industry. As businesses strive for greater efficiency and sustainability, the role of C channel steel roll forming machines will only become more critical. Investing in this technology not only enhances production capabilities but also positions manufacturers to better serve their clients in an increasingly competitive marketplace.

In conclusion, the C channel steel roll forming machine is a vital tool for industries requiring durable, high-quality steel products, proving itself to be a cornerstone of modern manufacturing processes.