Understanding C Channel Steel Roll Forming Machines

In modern construction and manufacturing, precision and efficiency are of paramount importance. One of the key players in achieving both is the C channel steel roll forming machine. This equipment is designed specifically to create C-shaped steel channels, widely used in various structural applications. This article delves into the functionality, benefits, and applications of C channel steel roll forming machines, shedding light on why they are indispensable in today’s industrial landscape.

What is a C Channel Steel Roll Forming Machine?

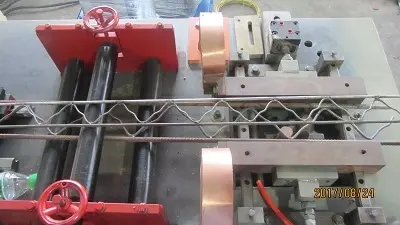

A C channel steel roll forming machine is a specialized piece of equipment that continuously bends and shapes flat steel strips into C-shaped profiles. The process involves feeding a sheet of steel into the machine, where it is progressively shaped through a series of rollers. These rollers apply pressure at specific points to achieve the desired cross-section, and adjustable features allow for the customization of dimensions and thicknesses based on requirements.

Benefits of Using C Channel Steel Roll Forming Machines

1. Precision Engineering One of the primary advantages of utilizing a C channel steel roll forming machine is the precision it offers. The equipment is designed to create uniform profiles consistently, ensuring that the dimensions meet exact specifications. This precision reduces the amount of scrap metal generated during production, contributing to more efficient resource use.

2. High Production Efficiency C channel roll forming machines can produce a significant amount of material in a relatively short time. Automating the manufacturing process through this machinery minimizes labor costs and accelerates output, making it ideal for large-scale projects where time and efficiency are critical.

3. Versatility These machines are not limited to producing a single type of profile. With adjustments, they can manufacture various sizes and thicknesses of C channels, allowing manufacturers to cater to diverse project needs. This versatility enables companies to adopt a more flexible production approach, responding quickly to market demands.

4. Cost-Effectiveness Investing in a C channel steel roll forming machine can lead to substantial savings in the long run. The efficiency gains, combined with reduced material waste, allow for lower production costs. Furthermore, with the capacity to produce custom channels, companies can avoid the additional expenses associated with sourcing specialized parts from external suppliers.

5. Durability and Quality C channels are known for their strength and durability. The roll forming process enhances the structural integrity of the steel, making it suitable for load-bearing applications. Materials can be selected based on corrosion resistance and tensile strength, thereby ensuring that the final product meets high-quality standards.

Applications of C Channel Steel

C channel steel profiles are used across various industries. Common applications include

- Construction C channels are frequently employed in building frameworks, offering structural support for walls, roofs, and bridges due to their superior strength.

- Manufacturing In the manufacturing sector, these profiles serve as vital components in machinery and equipment, where they provide stability and support.

- Transportation C channels are often used in the construction of vehicles and trailers, contributing to their durability and ability to bear weights.

- Infrastructure For highways, railways, and other infrastructures, C channel steel elements support pavement structures and various installation requirements.

Conclusion

C channel steel roll forming machines are essential for streamlined manufacturing processes in various industries. Their ability to produce high-quality, precise components makes them invaluable in construction, manufacturing, and infrastructure projects. By investing in such technology, businesses not only enhance their operational efficiency but also meet the growing demands for customized steel products. With continuous advancements in technology, the future of roll forming is bright, promising even greater innovations that will further benefit industries reliant on steel fabrication.