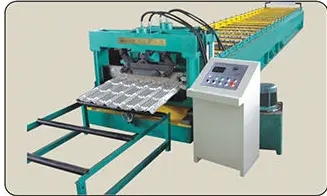

C-Channel Forming Machine A Key Player in Modern Manufacturing

In the realm of modern manufacturing, efficiency and precision are paramount. One of the essential tools that has revolutionized the production processes in various industries is the C-channel forming machine. This innovative equipment is designed to create C-shaped channels from metal sheets, which are widely used in construction, automotive, and manufacturing sectors.

A C-channel, also known as a C-beam or C-section, has a distinct shape resembling the letter C, which provides excellent structural integrity and versatility. C-channels are typically used for frames, supports, and as structural elements that bear loads. Given their importance in construction and manufacturing, the demand for high-quality C-channels has surged, prompting the need for advanced forming machinery.

C-Channel Forming Machine A Key Player in Modern Manufacturing

One of the significant advantages of using a C-channel forming machine is its ability to produce channels with consistent quality and exact specifications. Modern machines are equipped with advanced technology, allowing for automatic adjustment of parameters such as width, height, and thickness. This automation minimizes human error and enhances efficiency, resulting in a high throughput of finished products.

Additionally, the use of C-channel forming machines contributes to cost savings in production. When compared to traditional manufacturing methods, the speed and precision of these machines reduce material waste and operational time. This efficiency is vital for manufacturers looking to improve their productivity while maintaining quality standards.

Moreover, the versatility of C-channel forming machines is noteworthy. They can accommodate a wide range of materials, including galvanized steel, stainless steel, and aluminum. This adaptability allows manufacturers to cater to various client needs and produce channels for multiple applications, from lightweight structures to heavy-duty frameworks.

In the context of sustainability, C-channel forming machines also play a significant role. With rising concerns about environmental impact, manufacturers are increasingly focused on reducing waste and using sustainable materials. The precise nature of these machines allows for optimal use of metal sheets, minimizing scrap and promoting eco-friendly production practices.

In conclusion, the C-channel forming machine is an indispensable tool in contemporary manufacturing. Its ability to produce high-quality, precision-engineered C-channels efficiently makes it a critical asset across various industries. As technology continues to advance, we can expect further enhancements in these machines, leading to even greater efficiency, reduced costs, and an overall improvement in the manufacturing landscape. The future of construction and industrial manufacturing will undoubtedly benefit from the capabilities of C-channel forming machines, solidifying their place in the heart of production processes.