The Evolution and Importance of Carbon Steel ERW Pipe Making Machines

Carbon steel, known for its strength and durability, plays a crucial role in various industries, from construction to energy. In recent years, the demand for carbon steel products, especially Electric Resistance Welded (ERW) pipes, has surged due to their extensive applications. The equipment used to manufacture these pipes, specifically carbon steel ERW pipe making machines, has seen significant advancements, catering to the growing market needs.

Understanding ERW Pipes

Electrical Resistance Welding (ERW) is a process used to manufacture longitudinally welded pipes. In this method, flat carbon steel sheets are rolled into a tubular shape, and the edges are heated through electrical resistance before being pressed together to form a weld. This technique allows for the production of high-quality welded pipes suitable for various applications, including oil and gas transportation, water supply, and structural uses.

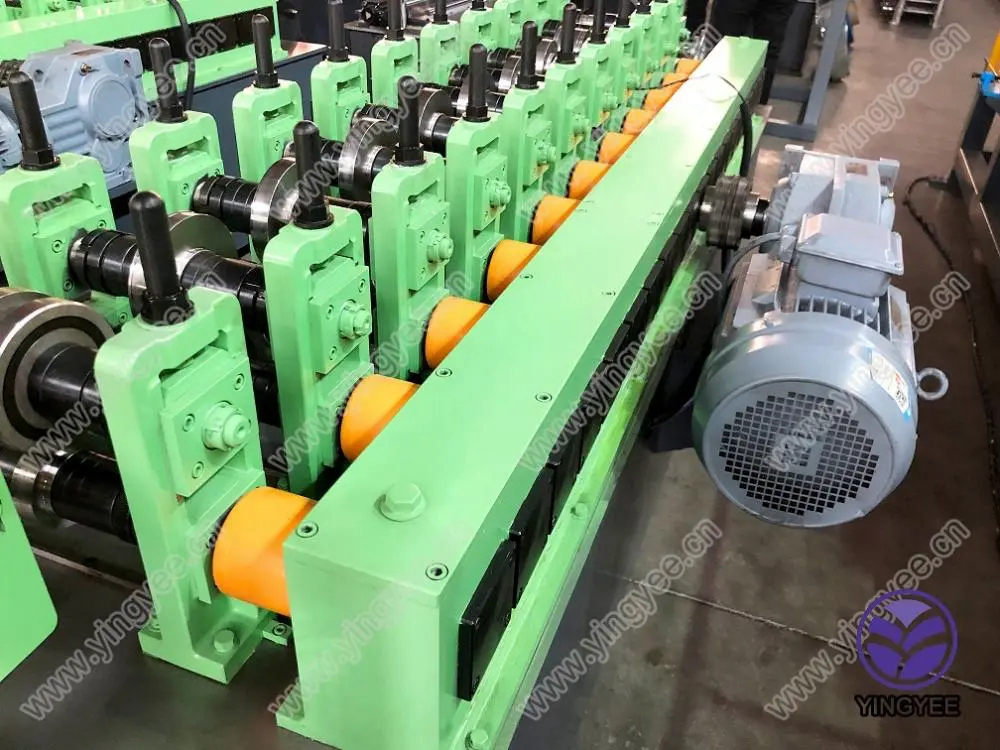

Key Features of Carbon Steel ERW Pipe Making Machines

1. High Efficiency Modern carbon steel ERW pipe making machines are designed for high-speed production. They can manufacture pipes at a rate of several hundred meters per minute, significantly increasing output and meeting industrial demands.

2. Precision Engineering These machines employ advanced technology to ensure precision in dimensions and wall thickness. This capability is crucial for maintaining the integrity of the pipes during operation, especially in high-pressure applications.

3. Automation and Control With the integration of automation and computer control systems, operators can easily monitor and adjust the production process in real time. This automation minimizes human error, enhances safety, and ensures consistent quality across batches.

4. Versatility Modern ERW pipe making machines can produce pipes of various sizes and specifications. This adaptability allows manufacturers to cater to diverse market needs and respond to changes in demand.

5. Energy Efficiency Advances in engineering have led to energy-efficient designs that reduce the overall energy consumption during the production process. This not only lowers operational costs but also aligns with global sustainability goals.

Economic and Environmental Considerations

The production of carbon steel ERW pipes is not only vital from an industrial standpoint but also has significant economic implications. The ability to manufacture these pipes in large quantities contributes to lower prices and wider availability, providing essential materials for infrastructural development.

Additionally, the carbon footprint associated with traditional pipe manufacturing processes has raised concerns within the industry. However, carbon steel ERW pipe making machines are increasingly implementing greener practices. They utilize recycled materials and reduce waste, contributing to more sustainable manufacturing processes.

The Future of ERW Pipe Manufacturing

As technology continues to evolve, the future of carbon steel ERW pipe making machines looks promising. Research and development are underway to incorporate advanced materials, such as high-strength low-alloy (HSLA) steel, to further enhance the performance of the pipes produced. Moreover, innovations in additive manufacturing and artificial intelligence may streamline operations and increase production capabilities.

Furthermore, the global push towards renewable energy sources and infrastructure improvement will drive the demand for carbon steel ERW pipes in various sectors, such as water management, energy distribution, and construction. Therefore, manufacturers who invest in advanced ERW pipe making technology are likely to maintain a competitive edge in the marketplace.

Conclusion

The significance of carbon steel ERW pipe making machines in the modern economy cannot be overstated. As the demand for high-quality, efficient, and sustainable pipe solutions continues to grow, these machines will remain at the forefront of manufacturing, driving innovation and meeting the needs of various industries. Ensuring the continuity and improvement of these machines will play a pivotal role in the future of construction, energy, and infrastructure development.