Understanding Cable Tray Making Machines An Essential Tool for Modern Infrastructure

In today's rapidly advancing technological landscape, the demand for efficient and organized electrical installations is continuously increasing. One of the pivotal components in meeting this demand is the cable tray. As an integral part of infrastructure for electrical wiring and cable management, cable trays provide support and organization for electrical cables, ensuring safety and accessibility. At the heart of the production of these essential units are cable tray making machines, which streamlines the manufacturing process and enhances the quality of the final product.

What is a Cable Tray?

Before delving into the significance of cable tray making machines, it's crucial to understand what a cable tray is. A cable tray is an open, modular system designed to hold and support electrical cables in commercial and industrial environments. They come in various types, including ladder trays, perforated trays, and solid-bottom trays, each serving specific applications based on load requirements and environmental conditions. The proper installation of cable trays not only streamlines cable management but also improves the safety and efficiency of electrical systems.

The Role of Cable Tray Making Machines

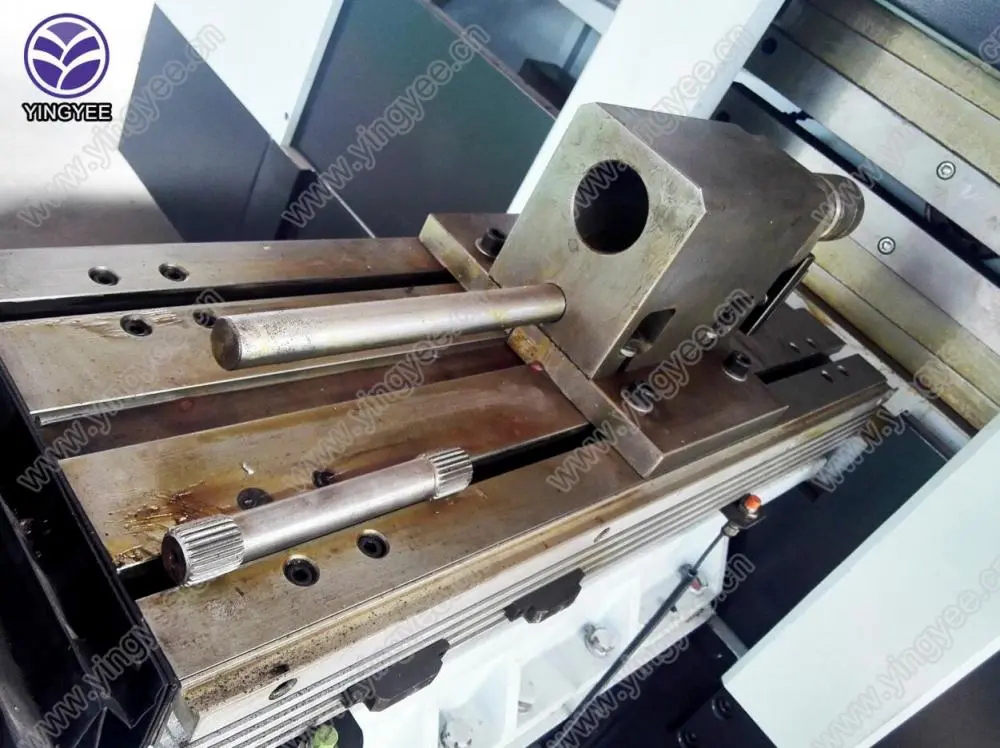

Cable tray making machines are specialized equipment designed to manufacture cable trays with precision and efficiency. These machines perform several functions, including cutting, bending, welding, and finishing, to ensure that the trays meet industry standards and customer specifications.

1. Automation Modern cable tray making machines often incorporate automation technology, which minimizes the need for manual labor. With automated systems, manufacturers can achieve high production rates, reduce labor costs, and minimize human error. Automation not only streamlines the manufacturing process but also increases overall efficiency, allowing businesses to meet rising demands promptly.

2. Versatility These machines are versatile in nature, enabling the production of various types and sizes of cable trays. Manufacturers can easily adjust the settings to produce trays that fit specific project requirements, whether for small residential setups or large-scale industrial applications.

3. Quality Control High-quality cable trays are essential for ensuring the safety and durability of electrical installations. Cable tray making machines are designed to maintain stringent quality control, with built-in systems for checking dimensions, weld integrity, and surface finish. This ensures that every cable tray produced meets or exceeds industry standards, minimizing the risk of failures or safety hazards in the field.

4. Cost-Effectiveness Investing in a cable tray making machine can significantly reduce manufacturing costs over time. With the ability to produce trays in-house, manufacturers save on material costs and transportation fees associated with outsourcing production. Moreover, faster production times lead to quicker turnaround on projects, allowing businesses to take on more work and improve their bottom line.

Importance in the Modern Market

As businesses and industries continue to invest in infrastructure development, the demand for reliable cable management solutions like cable trays is expected to rise. Cable tray making machines play a crucial role in fulfilling this demand. Their ability to produce high-quality products efficiently allows manufacturers to maintain a competitive edge in a crowded market. Moreover, with the growing trend toward green building and energy efficiency, the production of eco-friendly cable trays made from recyclable materials is becoming more prevalent, highlighting the importance of adaptable and innovative manufacturing processes.

Conclusion

Cable tray making machines are invaluable assets in the manufacturing industry, facilitating the production of essential components that play a crucial role in electrical installations. By leveraging advanced technology and automation, these machines not only enhance production efficiency but also ensure high-quality output—a combination that is increasingly important in an ever-evolving marketplace. As infrastructure projects expand globally, the importance of cable trays and the machines that manufacture them will continue to grow, underscoring their role in supporting safe and organized electrical systems.