The Future of Cable Tray Making Machines Advancements in Technology

In today's increasingly interconnected world, the demand for efficient and reliable electrical infrastructure is more crucial than ever. One of the essential components of such infrastructure is the cable tray, a system used to support insulated electrical cables and ensure their orderly arrangement. The manufacturing of these cable trays is a specialized process, and modern cable tray making machines have evolved significantly, incorporating advanced technologies that enhance efficiency, precision, and quality.

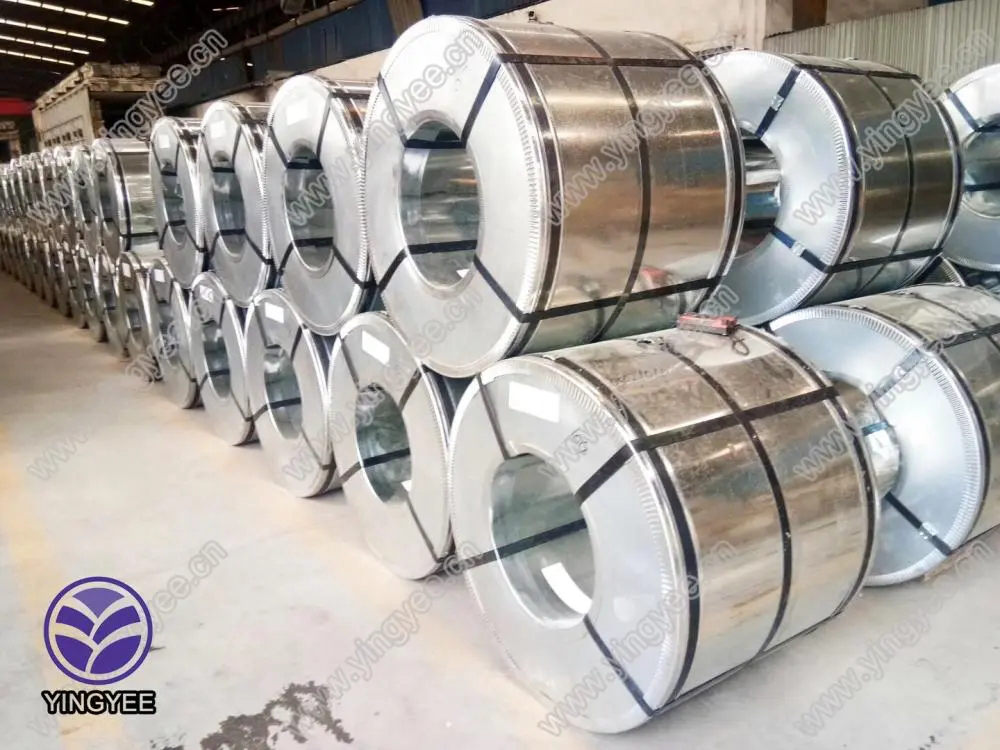

Cable tray making machines play a critical role in the production of various types of trays, including ladder trays, ventilated trays, and solid-bottom trays. These machines are designed to handle different materials, such as steel, aluminum, and fiberglass, allowing manufacturers to create trays suited for various applications—from large industrial settings to commercial buildings.

One of the most notable advancements in cable tray making technology is automation. Many manufacturers are now utilizing automated systems that streamline the production process. These machines can perform multiple functions, such as cutting, bending, and punching, all in one setup, significantly reducing the time and labor required for production. Automation not only increases output but also minimizes human error, ensuring that each tray produced meets strict quality standards.

Additionally, the integration of Computer Numerical Control (CNC) technology has revolutionized cable tray manufacturing. CNC machines allow for precise control over the production process, enabling the creation of intricate designs and custom sizes that meet the unique needs of clients. This level of precision ensures that cable trays fit perfectly in their designated spaces, reducing installation time and improving overall system efficiency.

As environmental concerns continue to rise, eco-friendly practices are becoming increasingly important in manufacturing. Many modern cable tray making machines are designed with sustainability in mind. They incorporate energy-efficient technologies and materials, reducing waste throughout the production process. Moreover, some machines are capable of recycling scrap materials generated during the manufacturing, further minimizing their environmental impact.

In terms of machine design, advancements have also focused on user-friendliness. Modern cable tray making machines feature intuitive interfaces that allow operators to easily program and monitor production parameters. This ease of use not only enhances operational efficiency but also provides training opportunities for new staff members, enabling companies to quickly adapt to workforce changes.

The durability and maintenance of cable tray making machines are also paramount. With the incorporation of high-quality materials and components, these machines are built to withstand the rigors of continuous operation. Regular maintenance features and predictive maintenance technologies help ensure that machines operate at peak performance, reducing downtime and lowering repair costs.

As the demand for cable trays continues to grow, driven by the expanding electrical infrastructure in various sectors—including telecommunications, construction, and renewable energy—innovations in cable tray making machines are expected to keep pace. Manufacturers will need to stay abreast of technological developments to remain competitive and meet the evolving needs of their customers.

In conclusion, the future of cable tray making machines is bright, with advancements in automation, precision, sustainability, and user-friendliness paving the way for increased efficiency in production. By embracing these innovations, manufacturers can produce high-quality cable trays that meet the demands of today's electrical infrastructure while also contributing to a more sustainable future. As technology continues to progress, we can anticipate even more exciting developments in this essential aspect of electrical engineering.