Cable Tray Roll Forming Machine An Essential Tool for Modern Infrastructure

In the rapidly evolving world of infrastructure and construction, the demand for efficient and reliable tools has never been higher. One such tool that has gained prominence is the cable tray roll forming machine. This advanced machinery plays a crucial role in producing cable trays, which are essential for organizing and protecting electrical cables in commercial, industrial, and even residential settings.

Cable trays are systems designed to support insulated electric cables used for power distribution and communication. They come in various designs, including ladder, perforated, and solid-bottom trays, each serving unique purposes. The primary function of a cable tray is to provide a safe and clean environment for cable management, reducing the risk of damage and facilitating maintenance.

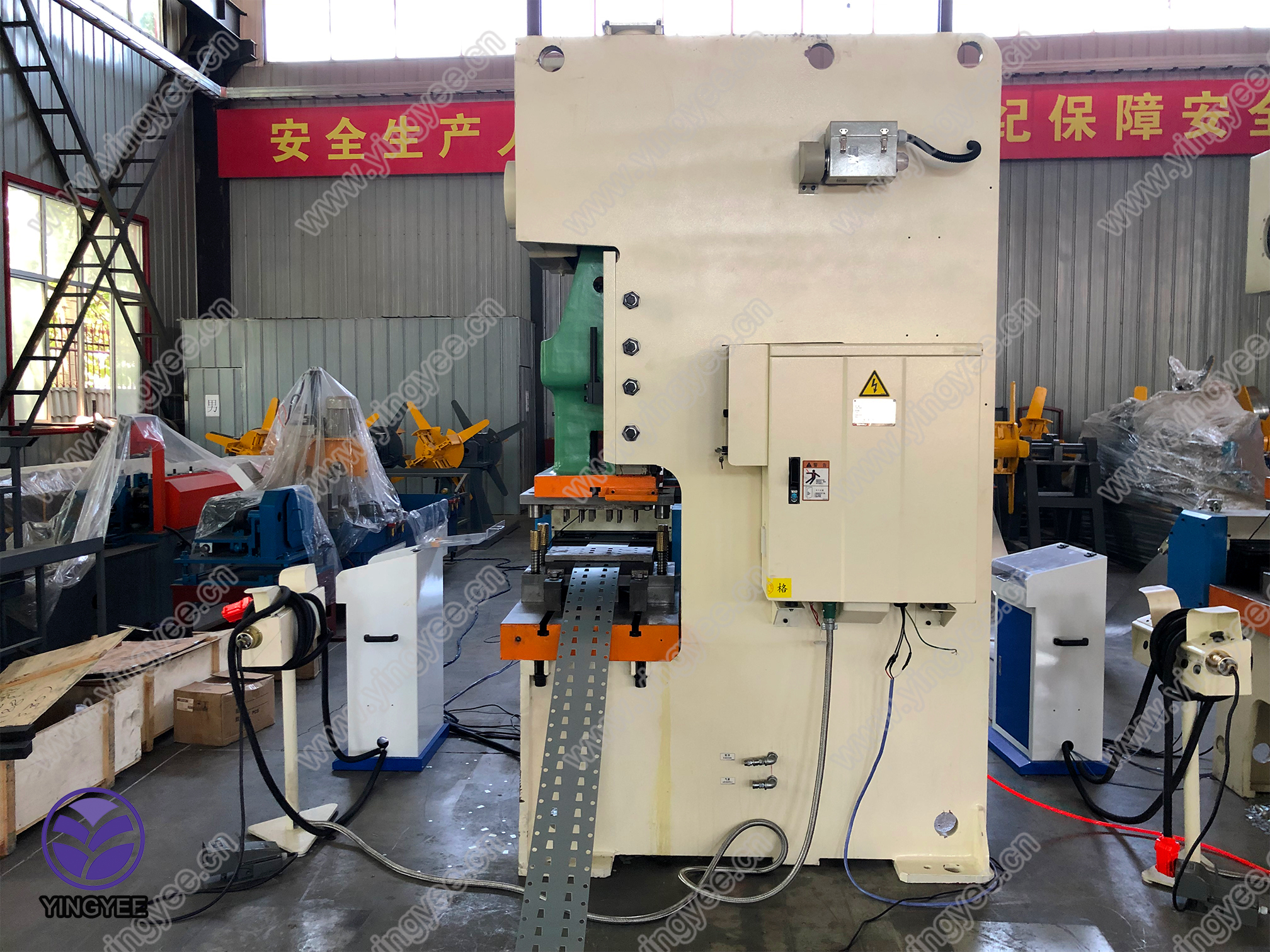

The cable tray roll forming machine specializes in manufacturing these trays with high precision and efficiency. The roll forming process involves feeding metal sheets into a series of rollers that mold the material into the desired shape. This method ensures a consistent production of trays with uniform dimensions, eliminating the discrepancies often seen with traditional manufacturing methods.

One of the significant advantages of using a cable tray roll forming machine is its automation capability. Modern machines can be programmed to produce various tray sizes and shapes with minimal human intervention. This not only speeds up the production process but also reduces labor costs. Automated systems can track production metrics, ensuring that manufacturers maintain high quality while scaling up their output to meet growing market demand.

Another notable aspect of these machines is their ability to work with different materials. While steel is the most commonly used material for cable trays due to its strength and durability, aluminum and other alloys are also suitable options. The versatility of the cable tray roll forming machine allows manufacturers to tailor their products according to the specific needs of their clients, whether for heavy-duty industrial applications or lightweight installations.

Moreover, energy efficiency has become a focal point in modern manufacturing, and the cable tray roll forming machine is no exception. Innovations in design and technology have led to machines that not only minimize energy consumption but also produce less waste. The ability to recycle scrap metal generated during the forming process further enhances the sustainability of this manufacturing approach.

In terms of market demand, the cable tray industry has witnessed substantial growth, driven by the booming construction sector and the rising need for reliable electrical infrastructure. As more buildings incorporate advanced electrical systems, the demand for high-quality cable management solutions continues to rise. This trend presents a lucrative opportunity for manufacturers equipped with state-of-the-art roll forming machines.

In conclusion, the cable tray roll forming machine is a vital component in the production of cable trays, enabling manufacturers to meet the increasing demands of the modern infrastructure landscape. Its automation, versatility, and energy efficiency make it an indispensable tool for achieving high-quality output with reduced operational costs. As the world continues to advance technologically, the need for effective cable management solutions will only grow, solidifying the cable tray roll forming machine's place in the manufacturing arena. Whether for new constructions or retrofitting projects, this equipment is essential for ensuring that electrical systems are organized, safe, and reliable.