Understanding the Importance of Buying Roofing Sheets Machinery

When it comes to construction and building projects, roofing plays a crucial role in ensuring the structure's durability, aesthetics, and weather resistance. To meet the growing demand for roofing sheets, businesses are increasingly investing in roofing sheets machinery. This article will explore the significance of purchasing roofing sheets machinery and its impact on productivity and quality.

The Need for Roofing Sheets Machinery

Roofing sheets are essential components in both residential and commercial buildings. They provide protection against the elements, enhance energy efficiency, and contribute to the overall design of the structure. With the construction industry's expansion, there is a heightened need for high-quality roofing sheets that can meet varying requirements. To fulfill this demand, manufacturers need efficient and reliable roofing sheets machinery.

Investing in advanced machinery can significantly boost production capabilities. With the right equipment, manufacturers can increase output while maintaining quality standards. This is especially crucial in competitive markets where timely delivery and superior products can make a substantial difference.

Types of Roofing Sheets Machinery

Roofing sheets machinery encompasses various types of equipment designed for the production of different roofing materials. Some of the common types include

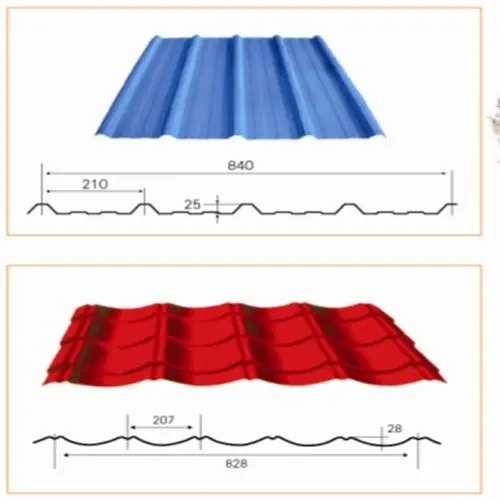

1. Roll Forming Machines These machines are used to shape metal sheets into various profiles required for roofing. They can produce a wide range of designs with precision and speed.

2. Cutting Machines Essential for ensuring that roofing sheets are cut to the desired length, these machines improve efficiency and reduce waste in the production process.

3. Punching Machines These machines create holes in the roofing sheets for fastening and other purposes. They are integral for ensuring that roofing systems are secure and functional.

4. Coating Machines To enhance durability and appearance, coating machines apply protective layers over roofing sheets. This ensures they can withstand harsh weather conditions and resist corrosion.

Factors to Consider When Buying Machinery

When considering the purchase of roofing sheets machinery, several factors should be evaluated

- Quality and Reliability The machinery should be of high quality, designed for heavy-duty use, and backed by a reliable warranty. This ensures longevity and minimizes downtime for repairs.

- Technology and Automation Modern machines come equipped with advanced technologies that can automate various processes, reducing labor costs and increasing efficiency.

- After-Sales Support A reputable manufacturer should offer robust after-sales support, including maintenance services and readily available spare parts, to ensure smooth operations.

- Cost-Effectiveness While initial investment is important, consider the long-term savings that high-quality machinery can provide through increased efficiency and reduced waste.

Conclusion

Investing in roofing sheets machinery is a strategic decision for any business in the construction industry. It not only enhances production capacity but also ensures the quality and consistency of the products manufactured. With the right machinery, companies can position themselves to meet market demands effectively and stay ahead of the competition. In an ever-evolving industry, having state-of-the-art roofing sheets machinery is not just a luxury; it has become a necessity for success. As you consider your options for purchasing this critical equipment, ensure you choose wisely to maximize your investment and contribute to the growth of your business.