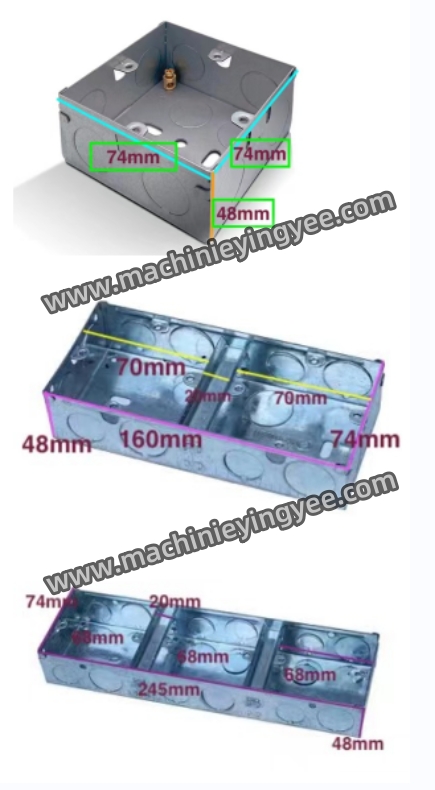

For this machine, we mainly has three types size, and they can be made in one machine if you want, by changing punching mold.

And the flow chart is as following:

2 tons decoiler with leveling machine →Servo feeder→200T pneumatic punch machine (add mold as you want)→Receiving

This maching has high efficiency work and high punching accuracy.

Speed: 30-40pcs/min

Work: Only need one person can finish the whole work

Automation can completely avoid the uncertainty of workers' operation. The automatic line punch and manipulator are controlled by PLC, with high accuracy, which can realize the perfect coordination of the entire production process.