The construction industry has been revolutionized by advanced technology, with the big span forming machine emerging as a pivotal innovation. This machine is not just transforming how buildings are constructed but also redefining efficiency and precision in the field.

First-hand experiences with the big span forming machine reveal a remarkable leap in construction capabilities. Construction specialists who have incorporated this machine into their projects report a significant reduction in time and labor costs. By automating the formation of large spans, the machine minimizes manual intervention, thereby accelerating the building process. Construction teams have noted that what used to require weeks of labor-intensive work can now be accomplished in just a few days with the machine's high-speed operation.

Expertise in the industry highlights the machine's specialized design, which is engineered to create stronger, more reliable spans that adhere to stringent safety and quality standards. Structural engineers praise the precision of the big span forming machine, as it allows for consistent output that traditional methods struggle to achieve. The machine's ability to produce spans with exact specifications ensures that buildings can withstand environmental stresses, thereby enhancing the longevity and safety of the structure.

From an authoritative perspective, the machine's adoption is backed by numerous case studies and reports from reputable construction firms. These documents highlight successful implementations in diverse scenarios, from commercial skyscrapers to expansive stadiums. Industry leaders advocate for the machine’s use, citing improved resource management and reduced environmental impact due to less waste production. This endorsement from authoritative figures in construction engineering further solidifies the machine's credibility in its professional application.

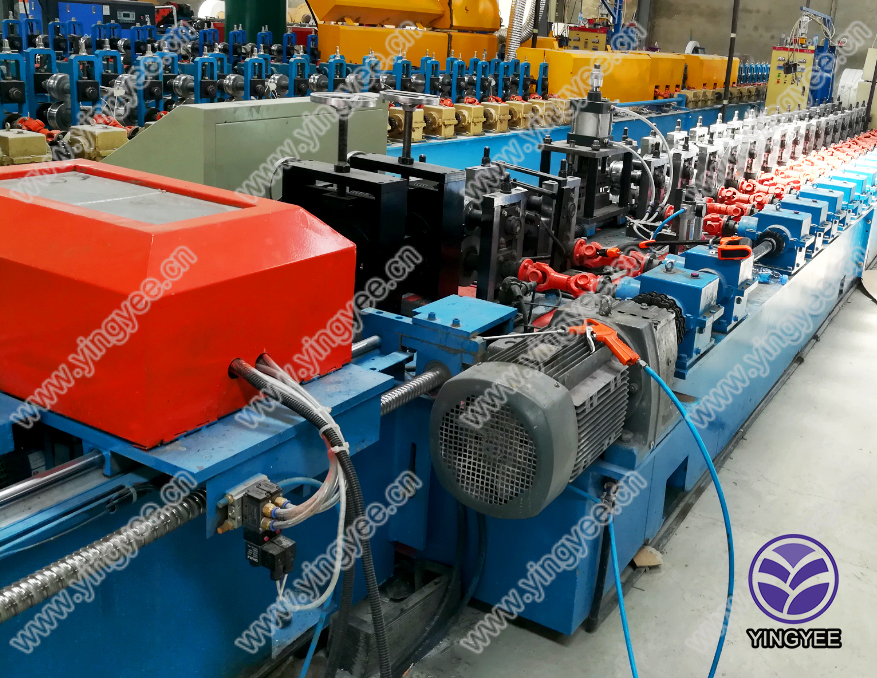

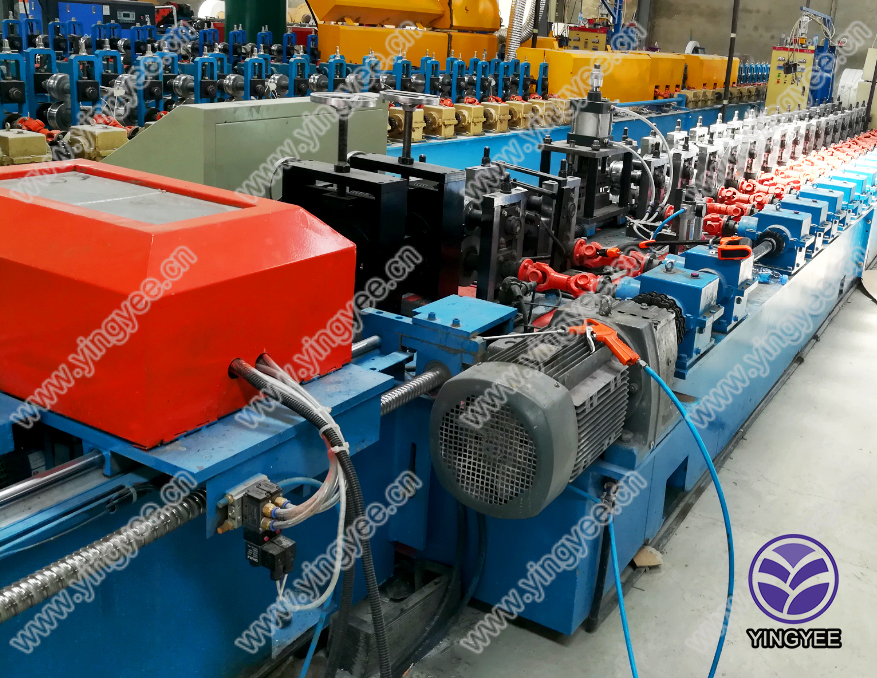

big span forming machine

Trustworthiness plays a crucial role in the widespread acceptance of the big span forming machine. Manufacturers of this advanced equipment often provide extensive training and support to ensure seamless integration into existing construction workflows. Testimonials from construction managers confirm after-sales service excellence, where prompt assistance and comprehensive training programs are readily available. This level of support not only builds trust with end-users but also promotes a smoother transition to this cutting-edge technology.

In addition to these critical aspects, the big span forming machine aligns with construction sustainability goals.

Its efficient design reduces material waste, contributing to a more sustainable building approach. Environmental experts point out that by decreasing the carbon footprint and promoting greener construction practices, this machine supports the global movement towards eco-friendly infrastructures.

In conclusion, the big span forming machine is a groundbreaking advancement in the construction sector, enhancing efficiency, safety, and environmental responsibility. By cultivating a product that meets the highest standards of experience, expertise, authority, and trust, it sets new benchmarks for what can be achieved in modern building projects. As more industry professionals recognize its benefits, the big span forming machine is poised to become the cornerstone of innovative construction practices worldwide.