The Big Span Forming Machine Revolutionizing Construction and Manufacturing

In the ever-evolving world of construction and manufacturing, one innovation that stands out is the Big Span Forming Machine. This remarkable piece of machinery is designed to create large structural components efficiently, providing a significant advantage in various sectors, including construction, aerospace, and automotive industries.

The Big Span Forming Machine Revolutionizing Construction and Manufacturing

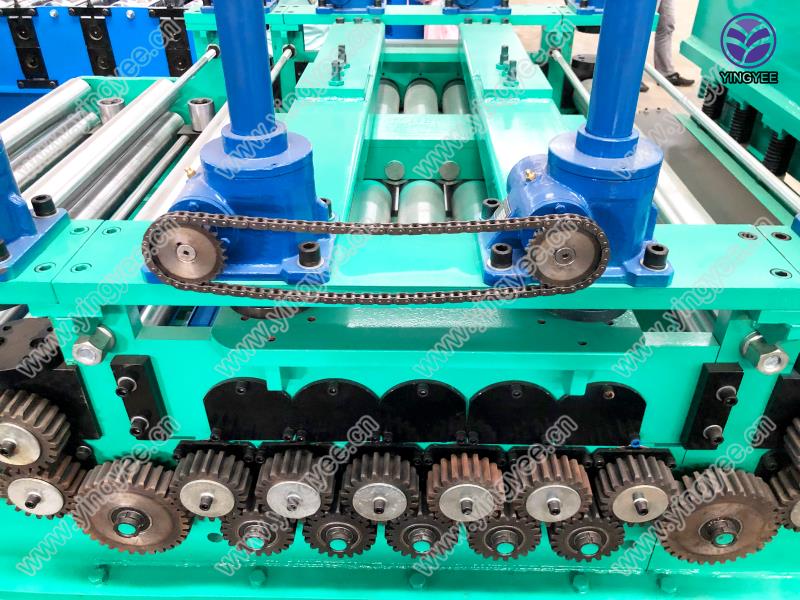

One of the key features of this machine is its ability to handle a variety of materials, including steel, aluminum, and composite materials. This versatility allows manufacturers to adapt the machine to different projects, thus expanding its application range. Moreover, the machine can produce components that meet stringent industry standards, ensuring safety and reliability.

The significance of the Big Span Forming Machine can be observed in its impact on construction projects. Large-span structures, such as bridges and arenas, require materials that can support significant weight while maintaining stability. The machine’s precision forming capabilities allow for the production of robust components that enhance the overall structural integrity. This not only improves safety but also reduces maintenance costs over the lifespan of the structure.

In addition to its applications in construction, the Big Span Forming Machine is also making waves in the aerospace sector. Aircraft manufacturers are increasingly using large components that must meet aerodynamic standards. The ability to produce large, lightweight, and durable structural elements is essential in designing aircraft that can withstand both operational stresses and environmental conditions. Consequently, the Big Span Forming Machine has become an integral part of the manufacturing process within this high-stakes industry.

Furthermore, the efficiency and speed provided by this machine contribute to a more sustainable manufacturing process. By reducing material waste and enabling faster production cycles, the Big Span Forming Machine aligns with current trends towards environmental consciousness and resource efficiency. Manufacturers are now able to produce high-quality components while minimizing their carbon footprint.

In conclusion, the Big Span Forming Machine represents a crucial advancement in the field of construction and manufacturing. Its ability to produce large, precise components quickly and efficiently addresses the growing demands of various industries. As technology continues to advance, the role of this innovative machine is expected to expand, paving the way for new possibilities in design and construction. Embracing such innovations not only enhances productivity but also fosters a sustainable approach to manufacturing, ensuring a brighter future for the industry.