The Benefits of Portable Rollforming Machines in Gutter Installation

In recent years, the construction and building maintenance sectors have witnessed a significant technological evolution, particularly in how gutters are installed. One of the most innovative developments is the portable rollforming machine, which has become an essential tool in gutter installation. This article explores the benefits of using portable rollforming machines and their impact on efficiency, quality, and ease of use in gutter installation.

Streamlined Installation Process

Portable rollforming machines simplify the gutter installation process. Traditionally, gutter systems required extensive pre-manufacturing and transportation, often leading to delays and increased costs. However, with a portable rollforming machine, contractors can create gutters on-site, allowing for immediate installation. This not only saves time but also reduces transportation costs associated with moving large, pre-formed gutters.

High Precision and Customization

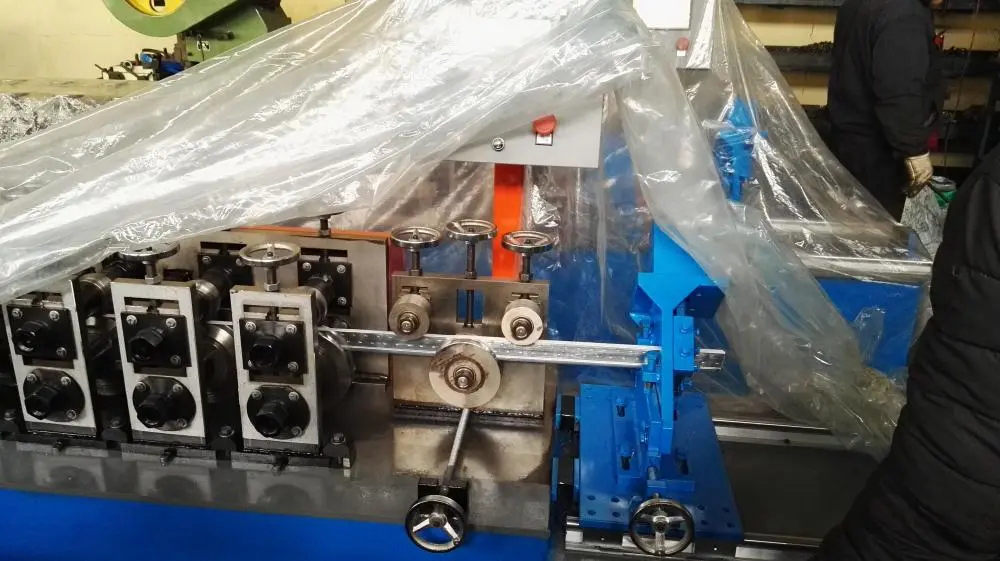

One of the standout features of portable rollforming machines is their ability to produce high-precision gutters tailored to specific project requirements. With adjustable settings and customizable profiles, contractors can create gutters that perfectly fit the dimensions and style of the building. This level of customization ensures a seamless look and enhances the overall aesthetics of the property.

Superior Material Efficiency

Using portable rollforming machines significantly improves material utilization. Unlike traditional methods that often rely on pre-manufactured sections, which can lead to waste due to misfits or excess materials, rollforming allows contractors to produce exactly what is needed on-site. This reduces scrap material and contributes to cost savings and environmentally friendly practices.

Enhancing Quality Control

Quality control is crucial in construction, particularly for components like gutters that play a vital role in water management and building integrity. Portable rollforming machines allow contractors to oversee the full production process, ensuring that every gutter section meets the highest standards. This capability reduces the chances of defects and repairs down the line, ultimately leading to greater satisfaction for both contractors and property owners.

Portability and Versatility

As implied by the name, portability is a key advantage of these machines. They can be easily transported from one job site to another, making them suitable for both large-scale projects and smaller residential installations. Their versatility extends beyond just gutter installation; rollforming machines can be adapted to create various building components, including roofing and siding, making them a valuable addition to any contractor’s toolkit.

Reducing Labor Costs

The efficiency gained from using portable rollforming machines can also lead to reduced labor costs. With the ability to produce gutters on-site quickly, fewer labor hours are needed for both manufacturing and installation. Additionally, the ease of use of these machines allows for faster training of new employees, further optimizing workforce productivity.

Weather Resistance and Longevity

The materials produced by portable rollforming machines often exhibit superior durability and resistance to weather-related damage. For instance, many machines are equipped to handle metals such as aluminum and galvanized steel, which are known for their longevity and low maintenance requirements. This attribute translates into lower replacement and repair costs over the lifetime of the gutter system.

Conclusion

The incorporation of portable rollforming machines in gutter installation workflows presents numerous benefits that cater to the needs of modern construction. From streamlining the installation process and allowing for customized solutions to enhancing quality control and reducing costs, these machines are transforming how contractors approach gutter systems. As technological advancements continue to shape the construction industry, it's clear that portable rollforming machines are not just a trend but rather a significant enhancement in the art of building construction and maintenance. Embracing this innovation not only improves project outcomes but also elevates the standards of quality and efficiency in the industry as a whole.