Understanding Barrel Corrugated Roof Sheet Forming Machines

In the world of construction and architecture, roofing plays a crucial role in determining not only the aesthetics of a building but also its durability and functionality. Among the various roofing options available, barrel corrugated roof sheets have gained significant popularity due to their unique structural characteristics and visual appeal. To cater to the growing demand for these roofing sheets, the barrel corrugated roof sheet forming machine has emerged as an essential piece of equipment in the manufacturing industry.

The barrel corrugated roof sheet forming machine is designed to produce roof sheets that feature a distinctive curved wave pattern, resembling the shape of a barrel. This design not only enhances the roof's visual appeal but also provides improved strength and durability. The corrugation allows for better water drainage, minimizing leakage issues and increasing the lifespan of the roofing material. Furthermore, the lightweight nature of these sheets makes them easier to handle and install, reducing labor costs and installation time.

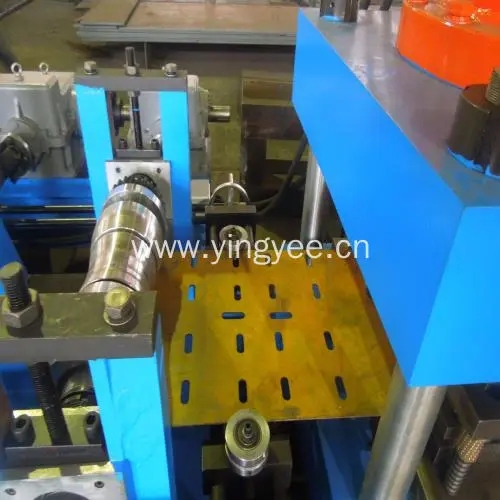

The manufacturing process begins with the preparation of raw materials, typically galvanized steel or aluminum. These materials are chosen for their resilience against weather elements and corrosion. Once the raw materials are ready, they are fed into the barrel corrugated roof sheet forming machine, which utilizes a series of rollers to shape the metal sheets. The machine is equipped with advanced technologies that ensure precision and consistency in the production process.

One of the standout features of modern barrel corrugated roof sheet forming machines is their automation capabilities. Many machines are fitted with computerized control systems that allow for precise adjustments in the forming process. This automation not only enhances efficiency but also minimizes material waste, making the production process more sustainable. Operators can easily program different specifications, enabling the production of customized sheets tailored to specific project requirements.

Moreover, the design of the machine ensures that it can handle various thicknesses and widths of raw materials. This versatility is essential, as construction projects often demand a range of specifications. With the ability to produce different profiles and dimensions, manufacturers can meet the diverse needs of their clients, from residential buildings to industrial complexes.

Safety is another critical consideration in the operation of barrel corrugated roof sheet forming machines. Manufacturers are incorporating safety features such as emergency stop buttons, safety guards, and sensors to protect operators during the production process. These measures are essential in minimizing workplace accidents and ensuring a safe working environment.

In conclusion, barrel corrugated roof sheet forming machines play a pivotal role in the production of modern roofing solutions. Their advanced technology, efficiency, and versatility cater to the growing demand for stylish and durable roofing materials in the construction industry. As architecture continues to evolve, the importance of such machines will only increase, contributing to safer, more aesthetically pleasing, and sustainable building practices. The continuous innovations in this field promise a bright future for both manufacturers and builders alike.