Understanding the intricacies of an automatic T ceiling production line is a transformative experience for professionals in the construction and manufacturing industries. This specialized machinery plays a crucial role in the seamless fabrication of T-shaped ceiling grids, which are essential for modern architectural designs. The following insights delve into the operational efficiencies, technical expertise, and the authoritative position of this technology in today's market.

An automatic T ceiling production line integrates advanced automation with precision engineering, reducing labor-intensive processes while improving production speed and product consistency. The main advantage lies in its ability to operate with minimal manual intervention, thanks to a comprehensive array of sensors, actuators, and computer-controlled systems. These components work in harmony to ensure that each product meets exacting standards, a crucial requirement for both aesthetic and structural purposes.

Real-world experience shows that implementing an automatic T ceiling production line can lead to a significant reduction in material waste. By utilizing sophisticated programming and cutting-edge machinery, the system optimizes raw material usage, thereby lowering costs and supporting sustainable practices. This makes the production line not only a smart financial investment, but also an environmentally conscious one.

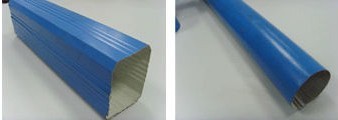

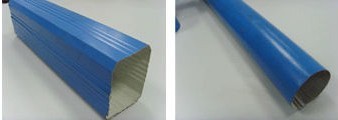

Precision and customization are the hallmarks of a high-caliber automatic T ceiling production line. It allows manufacturers to tailor the specifications, such as width, length, and thickness of the T ceiling grids, to meet diverse client demands. The flexibility offered by this equipment ensures that businesses can adapt to market changes quickly, maintaining their competitive edge. Moreover, the swift changeover capabilities between runs minimize downtime and maximize productivity.

automatic t ceiling production line

Another critical aspect is the expertise needed to manage and maintain such a production line. Operators require specialized training to oversee the complex systems within the machinery. A profound understanding of both mechanical functions and software systems is essential, ensuring smooth operation and timely troubleshooting. Manufacturers often provide comprehensive training programs and support to equip operators with the necessary skills, thereby enhancing the overall reliability and efficiency of the production process.

The authority of a manufacturer lies in their commitment to quality and innovation. Companies producing these advanced lines often invest heavily in research and development to introduce cutting-edge features that set them apart from competitors. Many maintain ISO certifications and adhere to rigorous industry standards, offering clients assurance of their product's integrity and performance. Partnerships with leading technology providers further solidify a manufacturer's position as a leader in the field.

Trustworthiness is fundamentally tied to the consistency and reliability of the production line's output. Through continuous quality checks and the use of durable materials, manufacturers ensure that their equipment performs optimally under demanding conditions. Case studies from satisfied customers highlight the long-term benefits of installing such technology, reinforcing the trust placed in the system's ability to deliver high-quality products repeatedly.

In conclusion, an automatic T ceiling production line exemplifies the pinnacle of modern manufacturing technology with its blend of efficiency, precision, and adaptability. This transformative equipment is designed to meet the demanding needs of the construction industry, providing superior products while minimizing operational costs. Stakeholders in the industry recognize the critical role these production lines play in driving innovation and maintaining a competitive edge. As construction trends continue to evolve, embracing this cutting-edge machinery will undoubtedly be a pivotal step towards future success in the market.