The Automation of T-Ceiling Production Revolutionizing Manufacturing Efficiency

In today’s fast-paced industrial landscape, the quest for efficiency and productivity has led to significant advancements in manufacturing technologies. One area that has seen considerable innovation is the production of T-ceilings, commonly known as suspended or drop ceilings. With the rise of automation, the production line for T-ceiling systems is being transformed, leading to reduced labor costs, improved accuracy, and enhanced product quality.

What are T-Ceilings?

T-ceilings are widely used in commercial and residential buildings for aesthetic appeal, acoustic control, and easy access to overhead utilities. The components of T-ceilings include the main runners, cross tees, and ceiling tiles, which together create a grid structure to support the ceiling tiles. Traditionally, the manufacturing process of these components was labor-intensive, involving manual handling and assembly. However, with advancements in technology, automated production lines are revolutionizing this sector.

Key Components of an Automated T-Ceiling Production Line

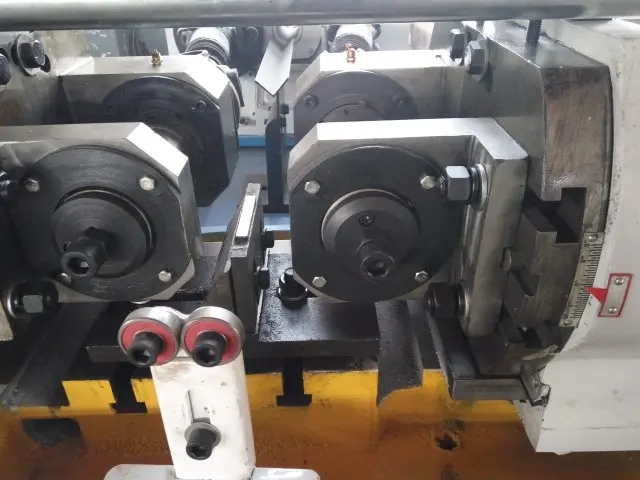

An automated T-ceiling production line consists of several key components, each designed to streamline the production process. The integration of robotics, conveyor systems, and computer numerical control (CNC) machines has allowed manufacturers to achieve previously unattainable levels of efficiency.

1. Robotic Automation Robots can handle tasks such as cutting, shaping, and assembling components with high precision. These machines can operate continuously, reducing the downtime associated with manual labor. This not only speeds up production but also minimizes the chances of human error.

2. Conveyor Systems Automated conveyor systems transport materials and components seamlessly throughout the production line. This ensures that every part moves efficiently to the next stage of production, reducing waiting times and improving overall workflow.

3. CNC Machines Computer numerical control technology enables precise cutting and shaping of materials according to specifications. CNC machines can produce intricate designs that are consistent in quality, thus enhancing the aesthetic appeal of the final product.

Benefits of Automation in T-Ceiling Production

The automation of T-ceiling production lines yields numerous benefits that significantly enhance manufacturing operations

- Increased Efficiency Automated systems can operate at a much higher speed compared to manual labor. This leads to shorter turnaround times and the ability to meet growing customer demands.

- Cost Reduction While the initial investment in automation technology may be substantial, the long-term savings in labor costs and the reduction of waste can lead to increased profitability. Moreover, automation reduces the need for extensive workforce training, as the technology operates with minimal human intervention.

- Enhanced Quality Control Automated systems provide consistent quality assurance. With precision engineering and real-time monitoring, manufacturers can detect and address issues early in the production process, ensuring that only top-quality products reach the market.

- Flexibility and Scalability Automated production lines can be easily adjusted to accommodate different production volumes or new product designs. This flexibility allows manufacturers to adapt quickly to market trends and shifting consumer preferences.

Conclusion

The automation of T-ceiling production lines represents a significant advancement in manufacturing technology. By embracing robotic automation, conveyor systems, and CNC machines, manufacturers can achieve unparalleled efficiency and quality in their production processes. As the demand for innovative building solutions continues to grow, the integration of automation will remain a driving force behind the evolution of T-ceiling manufacturing. With these advancements, industries can better meet the challenges of modern construction, ultimately leading to more sustainable and economically viable building practices.