The Evolution and Impact of Automatic Steel Frame Roll Forming Machines in Drywall Construction

In the realm of modern construction, efficiency and precision are paramount. One innovation that has transformed the industry is the automatic steel frame roll forming machine. Specifically designed for producing steel studs, tracks, C channels, and other critical components for drywall construction, these machines have significantly improved productivity and quality in building systems.

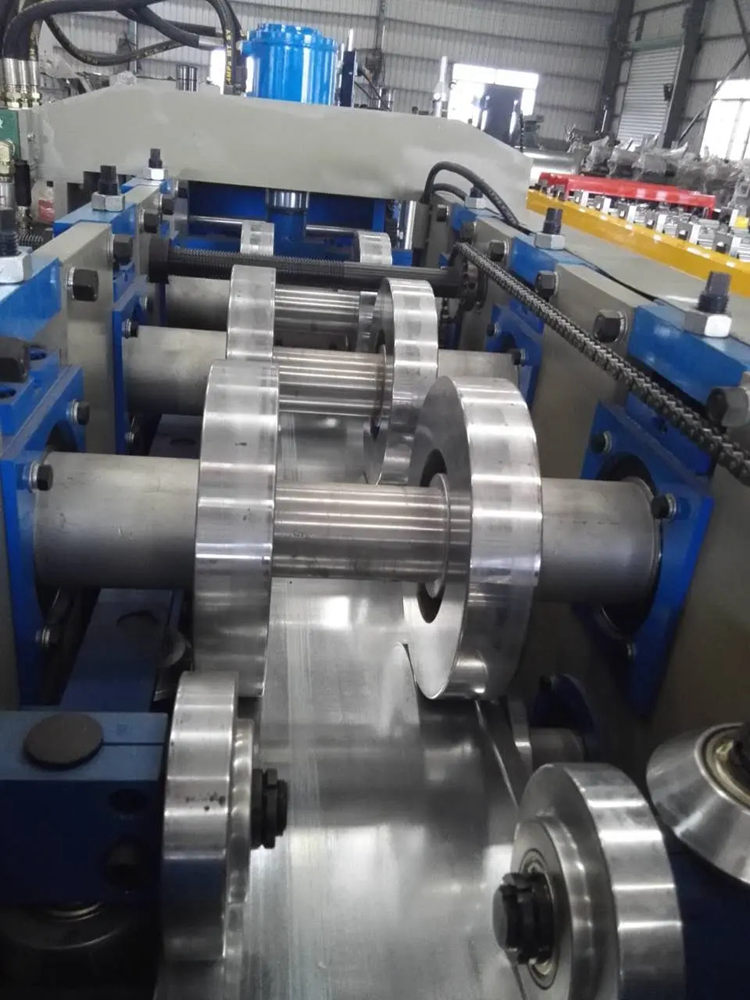

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which metal strips are gradually shaped into desired profiles through a series of meticulously aligned rollers. This technology allows for the mass production of uniform steel components, essential in creating the framework of drywall systems. The automatic roll forming machine streamlines the production process, reduces manual labor, and enhances safety on construction sites by minimizing the need for handling heavy materials.

Key Features of Automatic Steel Frame Roll Forming Machines

1. High Efficiency Automatic machines can produce steel frames at a remarkably high speed, significantly surpassing manual production methods. This translates to faster project completion times, allowing contractors to meet tight deadlines without compromising on quality.

2. Precision Engineering Advanced CNC (Computer Numerical Control) technology ensures that each steel stud and track is manufactured to precise specifications. This accuracy is crucial in drywall construction as it directly impacts the installation process and the overall integrity of the building.

3. Versatility Modern roll forming machines can be easily adjusted to create a variety of profiles, including C channels, U shapes, and other specialized components. This versatility allows contractors to adapt to different architectural designs and structural demands without needing multiple machines for each profile.

4. Cost-Effectiveness By automating the production of steel frames, construction companies can significantly reduce labor costs associated with manual fabrication. Additionally, the efficiency of material usage minimizes waste, contributing to lower overall project costs.

5. Durability and Strength Steel, as a primary material in construction, offers exceptional durability and resistance to environmental factors. Automatic steel frame machines facilitate the production of high-quality, corrosion-resistant frames that ensure long-lasting performance.

Applications in Drywall Construction

The integration of automatic steel frame roll forming machines in drywall construction has been particularly impactful. These machines produce the essential components that form the skeleton of drywall installations, facilitating the creation of lightweight, yet strong wall systems. The use of steel frames is not only beneficial for traditional commercial buildings but has also been instrumental in the rise of modular and prefabricated construction.

As the construction industry increasingly shifts towards sustainability, the recyclability of steel frames aligns with eco-friendly building practices. Steel can be recycled without loss of quality, making its use an environmentally responsible choice in modern construction projects.

Conclusion

The advent of automatic steel frame roll forming machines represents a significant advancement in construction technology, particularly in drywall applications. By enhancing efficiency, precision, and cost-effectiveness, these machines are revolutionizing the way steel components are produced and utilized in building systems. As the demand for faster, more reliable, and sustainable construction methods grows, the role of automatic roll forming machinery will undoubtedly become even more critical in shaping the future of the construction industry.

In an ever-evolving field, embracing technological advancements such as automatic roll forming machines will not only improve operational capabilities but also position companies to thrive in a competitive market. By investing in these machines, construction firms can ensure they are prepared to meet the challenges of tomorrow while delivering high-quality, durable structures that stand the test of time.