Automatic Round Downspout Roll Forming Machine A Comprehensive Overview

In the realm of modern manufacturing, efficiency and precision are paramount, particularly in the construction and roofing industries. One of the innovative solutions that has gained traction in recent years is the automatic round downspout roll forming machine. This sophisticated piece of equipment is designed to streamline the production of downspouts, which are essential components for directing rainwater away from buildings, thus preventing water damage and enhancing structural integrity.

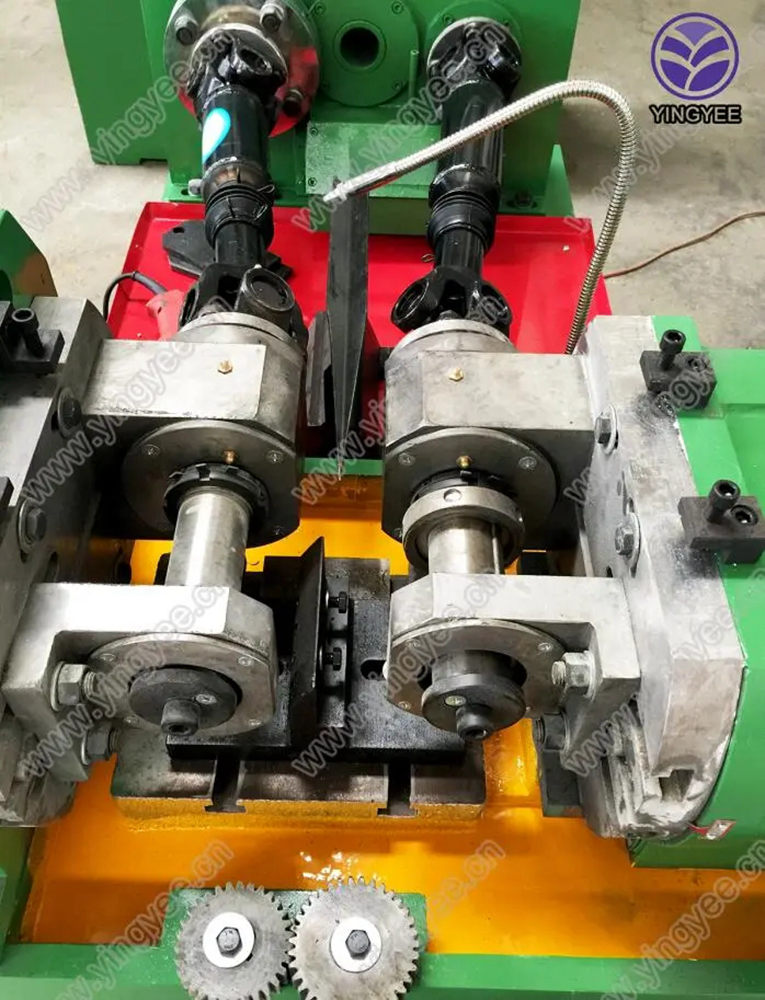

The primary function of an automatic round downspout roll forming machine is to convert flat metal sheets into finished downspouts of various sizes and lengths. This process begins with coil feeding, where a large coil of metal—typically aluminum or galvanized steel—is unwound and fed into the machine. The roll forming process involves passing the material through a series of rollers, each of which shapes the metal incrementally until the desired round shape is achieved.

One of the standout features of these machines is their automation capabilities. Equipped with advanced PLC (Programmable Logic Controller) systems, these machines can be programmed to produce downspouts at high speeds while maintaining accuracy. This automation minimizes human error, reduces labor costs, and enhances overall productivity. Operators can easily adjust settings to accommodate different specifications, ensuring versatility in production.

Additionally, the automatic round downspout roll forming machine often includes features such as automatic cutting to length, which ensures that each downspout is produced to the exact measurements required. This not only saves time but also reduces material waste, contributing to a more sustainable manufacturing process. Furthermore, these machines can be designed with additional processes in mind, such as punching holes or adding decorative elements, allowing manufacturers to offer customized solutions to their clients.

The benefits of using an automatic round downspout roll forming machine extend beyond efficiency and precision. By switching to automated systems, companies can significantly increase their output while maintaining consistent product quality. This is especially important in competitive markets where speed and reliability can set a business apart from its competitors.

In conclusion, the automatic round downspout roll forming machine represents a significant advancement in manufacturing technology. With its ability to produce high-quality downspouts quickly and efficiently, this machine serves as a valuable asset for manufacturers looking to enhance their production capabilities. As the demand for effective water management solutions continues to grow, investing in such innovative machinery will be crucial for businesses aiming to thrive in the ever-evolving construction industry.