Automatic Round Downspout Roll Forming Machine A Revolutionary Solution for Efficient Production

In the realm of metal forming technology, the automatic round downspout roll forming machine stands out as an innovative solution for manufacturers seeking efficiency, precision, and cost-effectiveness. This advanced machinery is specifically designed for the production of round downspouts, which are crucial components in modern drainage systems. As urban infrastructure expands and the demand for effective water management increases, the need for high-quality downspouts becomes more pronounced. This article explores the workings, benefits, and applications of the automatic round downspout roll forming machine.

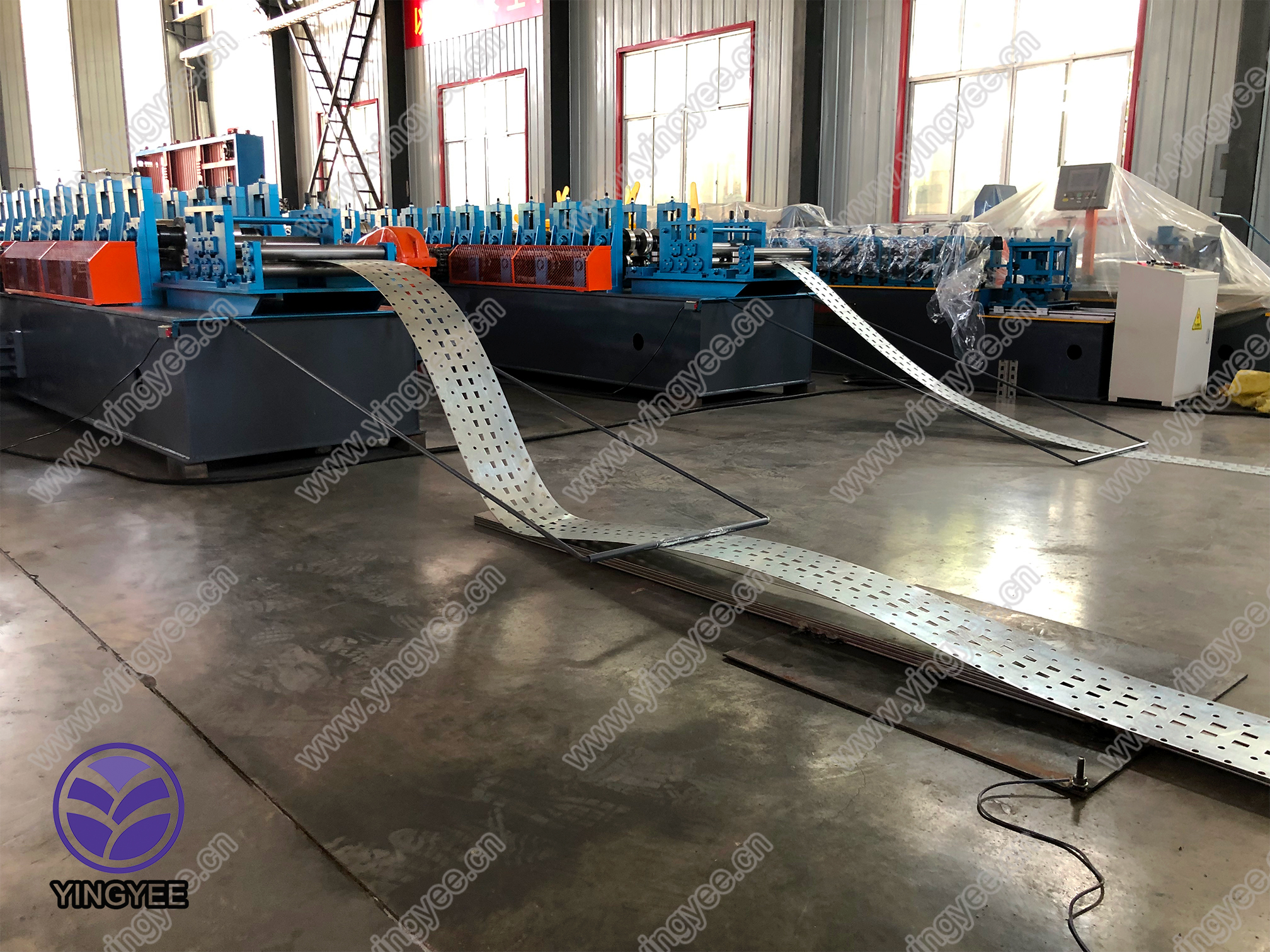

Understanding the Machine

The automatic round downspout roll forming machine is a type of machinery that converts metal sheets into intricately shaped components through a continuous bending process. It operates by feeding metal coils into a series of rollers, which gradually shape the material into round downspouts. The automation aspect of the machine means that the entire process – from feeding the raw material to cutting the final product – is streamlined, significantly reducing manual labor and production time.

This machine typically includes features such as a digital control system, which allows for precise adjustments to the roll forming process. Operators can easily program the dimensions, thickness, and length of the downspouts, ensuring uniformity and adherence to specifications. Furthermore, advanced technologies, such as PLC (Programmable Logic Controller) and human-machine interfaces (HMIs), enhance user control and operational efficiency.

Advantages of Automatic Roll Forming Machines

1. Efficiency One of the primary advantages of using an automatic round downspout roll forming machine is its efficiency. The automation of the production process minimizes the need for manual intervention, allowing for high-speed manufacturing. This results in a significant increase in the number of downspouts produced within a given timeframe.

2. Precision and Consistency The intricate design of the machine ensures that each downspout is produced with precision. Automated systems reduce the risk of human error, leading to consistent quality across large production runs. This is particularly important in construction and drainage applications, where uniformity is crucial for performance.

3. Cost-Effectiveness By reducing labor costs and increasing production speed, these machines can lower the overall costs of manufacturing. Additionally, the efficient use of raw materials minimizes waste, further enhancing cost savings. This economic advantage makes it an attractive option for both large manufacturers and small-scale operations.

4. Versatility Modern round downspout roll forming machines are versatile, capable of producing various sizes and shapes of downspouts. With minor adjustments, manufacturers can cater to specific customer requirements or project specifications, thus expanding their product offerings.

5. Durability Built with high-quality materials and advanced technology, these machines are designed for longevity. They can operate under demanding conditions without compromising performance, making them a worthwhile investment for manufacturers.

Applications in the Industry

The automatic round downspout roll forming machine is widely used in various sectors, including construction, architecture, and drainage management. In urban development projects, the need for effective rainwater management systems is paramount. Round downspouts are integral in directing rainwater away from buildings, preventing water damage and flooding.

Additionally, these machines are beneficial in the manufacturing of other related products, such as gutters and drainage pipes. Their adaptability allows manufacturers to diversify their output, meeting the growing demands of the construction industry.

Conclusion

In summary, the automatic round downspout roll forming machine represents a significant leap forward in manufacturing technology. Its ability to deliver efficient, precise, and cost-effective solutions makes it an invaluable asset for those in the metal fabrication industry. As the need for robust drainage solutions continues to rise, investing in this advanced machinery will undoubtedly position manufacturers for success in the competitive market. As technology evolves, the features and capabilities of roll forming machines are likely to advance further, opening new horizons for innovation and productivity in metal forming processes.