The Automatic Round Downspout Roll Forming Machine Revolutionizing Rainwater Management

In the realm of construction and building management, effective rainwater management systems are crucial for maintaining the integrity and longevity of structures. One of the most essential components of these systems is the downspout, which channels rainwater from rooftops away from the foundation of buildings. With the advancements in manufacturing technology, the automatic round downspout roll forming machine has emerged as a powerful tool, streamlining the process of creating efficient and durable downspout systems.

Understanding the Downspout Roll Forming Process

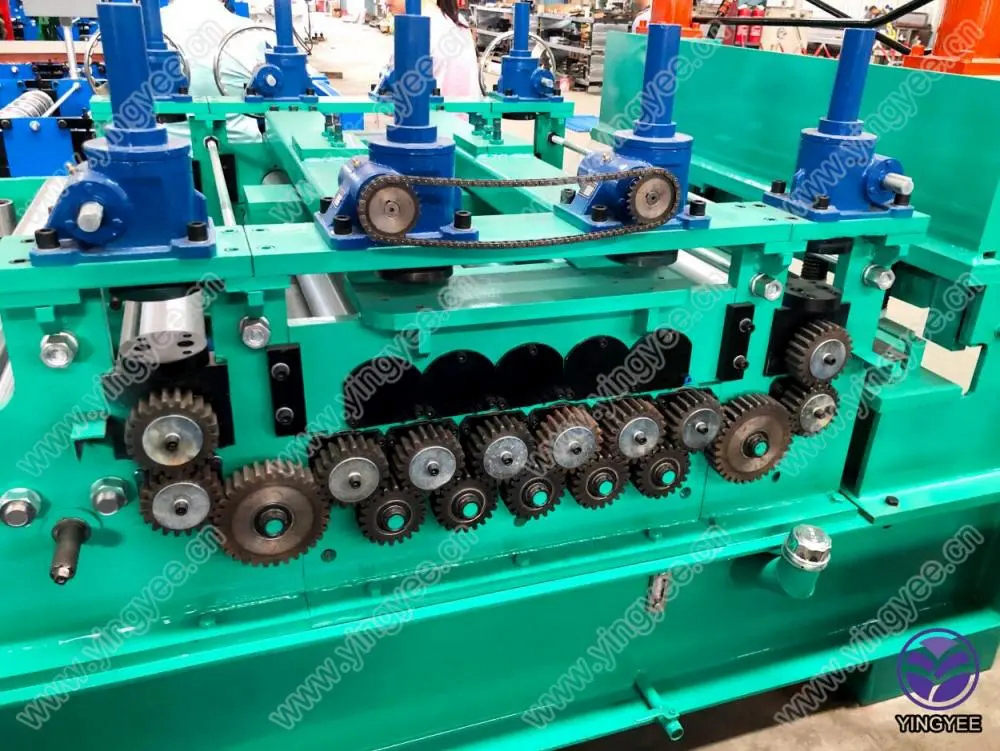

The roll forming process is a continuous bending operation in which a long strip of metal is passed through consecutive sets of rollers to gradually shape it into the desired cross-section. An automatic round downspout roll forming machine is specifically designed to produce round downspouts, an increasingly popular choice among builders due to their efficiency and aesthetic appeal.

Equipped with advanced technology, these machines automate the entire production process, significantly reducing labor costs and production time while maintaining high levels of precision. They can handle various materials such as aluminum, steel, and galvanized steel, allowing manufacturers to cater to different market needs and customer preferences.

Features and Benefits of Automatic Round Downspout Roll Forming Machines

1. Automation and Efficiency The primary advantage of automatic roll forming machines is their ability to operate with minimal human intervention. Operators can set parameters through a user-friendly interface, and the machine then runs through production cycles autonomously. This efficiency not only saves time but also minimizes the risk of human error.

2. Precision Production These machines utilize advanced control systems that ensure consistent quality across all products. The accuracy of the dimensions and profiles produced is critical, as any variance can lead to inefficiencies in the rainwater management system.

3. Versatility One of the notable aspects of the automatic round downspout roll forming machine is its adaptability. Manufacturers can easily change die sets to produce different sizes and thicknesses of downspouts as required by specific construction projects. This versatility makes it an invaluable asset in a dynamic and demanding construction market.

4. Reduced Waste The roll forming process is highly efficient in material usage, leading to less waste compared to traditional manufacturing methods. The continuous operation allows for longer runs of materials, which reduces the number of cuts and scrap generated.

5. Enhanced Durability The resulting downspouts from an automatic roll forming machine are often of higher quality due to the controlled forming process. These downspouts exhibit improved resistance to weathering, bending, and corrosion, making them ideal for a variety of environmental conditions.

Applications in Construction and Building Management

Automatic round downspout roll forming machines find extensive applications in both residential and commercial construction. They are often used in the production of rainwater downspouts for new buildings, renovations, and industrial projects. Their ability to produce customized sizes allows architects and builders to create unique designs while ensuring functional drainage solutions.

In addition to new constructions, these machines are also instrumental in the repair and maintenance of existing buildings. The ability to manufacture replacement downspouts on-demand minimizes downtime and helps maintain the aesthetic appeal and functional integrity of buildings.

Conclusion

The automatic round downspout roll forming machine represents a significant leap forward in the manufacturing of rainwater management systems. With their efficient processes, precision output, and versatility, these machines not only enhance the production capabilities of manufacturers but also contribute to sustainable building practices by minimizing waste and ensuring durability. As the construction industry evolves, the adoption of such advanced technologies will become increasingly vital in meeting the demands of modern architecture and environmental stewardship. Embracing these innovations will undoubtedly pave the way for more effective, efficient, and aesthetically pleasing solutions in rainwater management systems.