Automatic Round Downspout Roll Forming Machine An Innovative Solution for Efficient Manufacturing

In the ever-evolving world of construction and manufacturing, efficiency and precision are paramount. One of the most innovative contributions to this industry is the Automatic Round Downspout Roll Forming Machine. This advanced piece of machinery not only streamlines the production process but also ensures the consistent quality of downspouts, which are essential components in any building's drainage system.

Understanding the Downspout's Function

Before delving into the specifics of the roll forming machine, it is essential to understand what downspouts do. Downspouts are vertical pipes that channel rainwater from the roof of a building down to the ground, preventing water damage and erosion. Their design is critical; a well-crafted downspout must not only manage water flow effectively but also complement the architectural aesthetic of a building. This is where precision manufacturing becomes crucial.

The Role of Roll Forming Technology

Roll forming is a continuous bending process in which a long strip of sheet metal is passed through consecutive pairs of rolls to achieve the desired cross-section. This technique is favored for its ability to produce uniform shapes at high speeds with minimal waste. The Automatic Round Downspout Roll Forming Machine specifically utilizes this process to create round downspouts, facilitating quicker production rates and improved manufacturing consistency.

Key Features of Automatic Round Downspout Roll Forming Machines

1. High Efficiency and Speed These machines are designed for high-speed operations. Depending on the machine's specifications, it can produce tens of meters of downspout per minute, dramatically increasing output and reducing labor costs.

2. Automation Modern machines come equipped with advanced control systems that allow for fully automated operation. This minimizes human error, ensures precision, and reduces labor requirements, making the manufacturing process more cost-effective.

3. Customization One of the significant advantages of using roll forming technology is the machine's ability to produce downspouts of various diameters and lengths without the need for extensive retooling. Manufacturers can easily adjust settings to switch between different specifications, catering to specific architectural requirements.

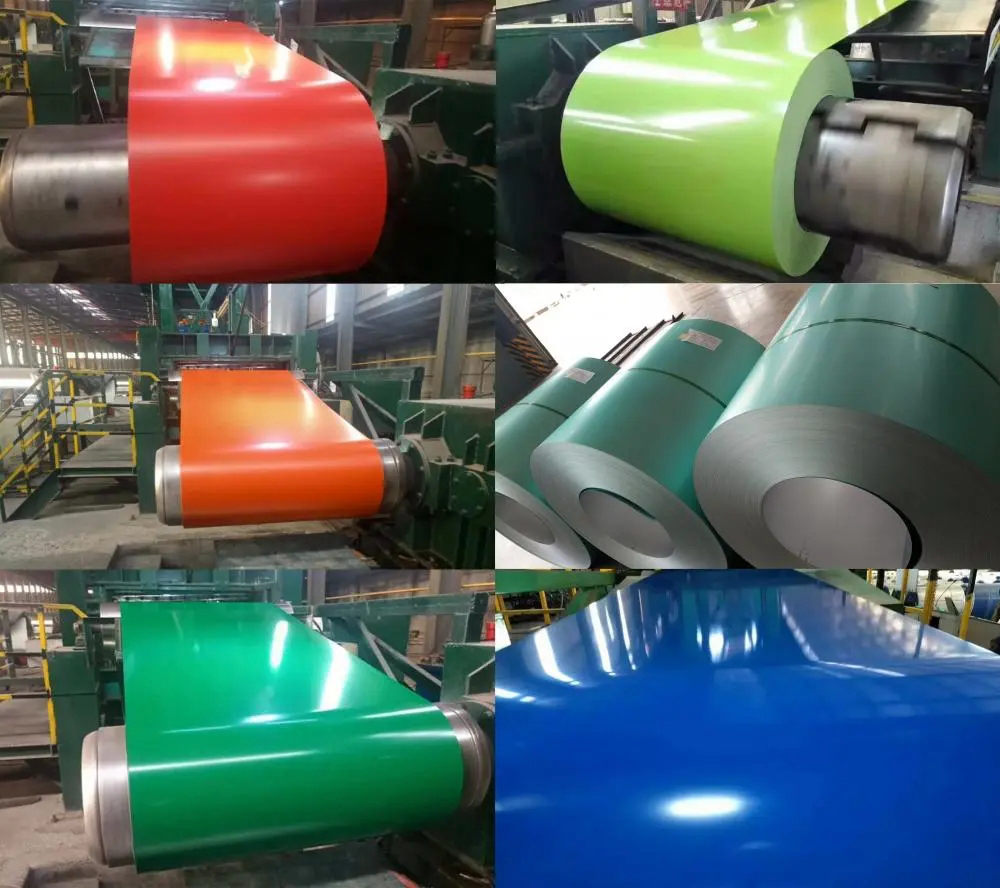

4. Material Versatility These machines can handle various types of materials, including galvanized steel, aluminum, and stainless steel. This versatility ensures that manufacturers can meet diverse client needs and adapt to changing market trends.

5. Durability and Maintenance Built from high-quality materials, automatic round downspout roll forming machines are designed for longevity. Their construction allows for ease of maintenance, ensuring that downtime is minimized and production remains stable.

Economic Benefits

Investing in an Automatic Round Downspout Roll Forming Machine can yield substantial economic benefits for manufacturers. The combination of increased production speeds, reduced labor costs, and less material waste ultimately leads to higher profit margins. Additionally, with the growing demand for efficient drainage systems in both residential and commercial buildings, companies equipped with advanced roll forming technology are well-positioned to capture a larger market share.

Environmental Impact

The importance of sustainable practices in manufacturing cannot be overemphasized. The automatic features of these machines lead to less waste during the production process, aligning with environmentally friendly initiatives. Moreover, the materials used in the production of downspouts can often be recycled, further enhancing the sustainability of the operation.

Conclusion

The Automatic Round Downspout Roll Forming Machine represents a significant advancement in the construction and manufacturing industries. Its ability to produce high-quality, customizable downspouts at an efficient rate showcases the potential of modern technology to improve traditional manufacturing processes. As the demand for effective drainage solutions continues to grow, investing in such innovative machinery will undoubtedly provide manufacturers with a competitive edge, ensuring they meet evolving consumer needs while maintaining profitability and sustainability.