The Innovative Automatic Round Downspout Roll Forming Machine

In the construction and manufacturing industry, efficiency and precision play pivotal roles in producing high-quality components. One of the remarkable advancements in this sector is the automatic round downspout roll forming machine. This technology not only enhances productivity but also ensures uniformity in the production of round downspouts, which are essential for effective water drainage systems.

Round downspouts are critical components in building structures, designed to direct rainwater from gutters to the ground or drainage systems. Traditionally, the manufacturing of these downspouts involved a labor-intensive process that often resulted in inconsistencies in size and shape. With the introduction of automatic roll forming machines, the industry has witnessed a substantial transformation.

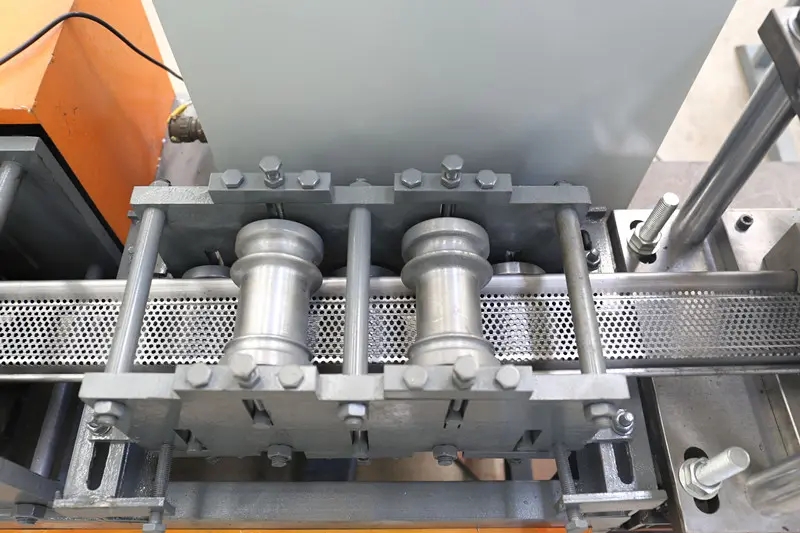

The automatic round downspout roll forming machine operates on a sophisticated mechanical system that feeds metal coils through a series of rollers. These rollers progressively shape the flat metal into a circular profile, forming the downspout’s distinct round shape. The automation aspect of this machine significantly reduces human intervention, decreasing labor costs while maximizing output.

One of the main advantages of using an automatic roll forming machine is its ability to produce high volumes of downspouts in a short period. This efficiency is particularly beneficial for large construction projects where time is of the essence. Additionally, the machine can be programmed to produce downspouts of varying diameters and lengths, allowing manufacturers to meet diverse customer needs without significant downtime.

Precision is another critical factor in the production of round downspouts. The advanced design of the automatic roll forming machine ensures that each downspout produced meets stringent quality standards. The machine incorporates computerized controls that monitor and adjust the forming process, minimizing the risk of defects and ensuring that every unit is produced to exact specifications. This level of consistency not only boosts customer confidence but also reduces material waste, ultimately leading to cost savings for manufacturers.

Furthermore, the integration of this technology is environmentally friendly. The efficient use of materials minimizes scrap, while advanced machinery is often designed to consume less energy compared to traditional manufacturing methods. As sustainability becomes a crucial consideration in construction, using energy-efficient machines aligns with global efforts to reduce carbon footprints.

Maintenance of automatic round downspout roll forming machines is relatively straightforward, which is a significant advantage for manufacturers. Regular servicing and inspections are usually sufficient to keep these machines in optimal working condition, ensuring that production remains uninterrupted. Many manufacturers also offer training and support for operators, facilitating a smoother transition to using these advanced machines.

In conclusion, the automatic round downspout roll forming machine represents a significant leap forward in the manufacturing process of round downspouts. By enhancing efficiency, ensuring precision, and promoting sustainability, this technology is poised to revolutionize how downspouts are produced. As the construction industry continues to evolve, investing in such innovative machinery will likely become a standard practice, helping manufacturers meet growing demands while maintaining high-quality standards.