The Evolution of Automatic Downspout Steel Square and Round Pipe Machines

In the construction and manufacturing industries, the demand for efficient and precise machinery has become increasingly significant. One such innovation that has revolutionized manufacturing processes is the automatic downspout steel square and round pipe machine. This piece of equipment plays a crucial role in crafting essential components used in roofing systems, drainage solutions, and various construction applications.

Understanding the Basics

Before diving deeper into the technology behind these machines, it’s important to understand what downspouts are. Downspouts are vertical pipes that direct rainwater from the roof of a building down to the ground or into a drainage system. They help in preventing water from accumulating around the foundation of a structure, which could lead to significant damage over time. The need for effective downspouts has led to the evolution of specialized machinery that can create high-quality pipes with varying dimensions and specifications.

Features of Automatic Downspout Steel Pipe Machines

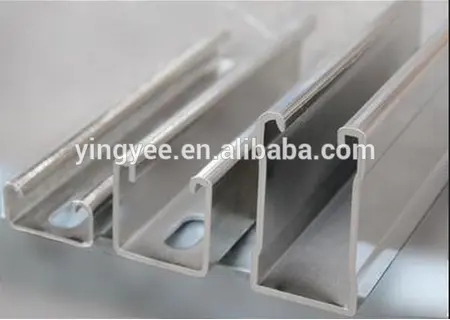

Automatic downspout machines are designed to produce both square and round pipes efficiently. These machines typically feature advanced technology that allows for the automation of cutting, shaping, welding, and finishing processes. Key features of these machines include

1. Precision Engineering One of the standout attributes of automatic downspout machines is their capacity for precision. Using computer numerical control (CNC) technology, these machines ensure that each pipe produced meets exact specifications, minimizing waste and enhancing quality.

2. Versatility Modern machines are capable of producing various sizes and shapes of downspouts. Whether square or round, these machines can seamlessly switch between formats, catering to diverse project requirements without the need for extensive adjustments.

3. Speed and Efficiency With high production rates, automatic downspout machines can produce hundreds of pipes in a short amount of time. This efficiency not only accelerates construction timelines but also reduces labor costs, making it a valuable investment for manufacturers.

4. Durability Built with robust materials and designed to withstand the rigors of industrial use, these machines are engineered for longevity. Regular maintenance ensures continued high performance and minimizes downtime in manufacturing processes.

5. Easy Operation Equipped with user-friendly interfaces, these machines simplify the operations, allowing even those with minimal technical knowledge to operate them with ease. This is particularly beneficial in training new employees, as they can quickly learn to use the machines safely and effectively.

The Manufacturing Process

The manufacturing process begins with the feeding of raw steel coils into the machine. The machine then employs a series of rollers to shape the steel into the desired pipe formation. Once shaped, the edges are often welded together to create a strong and seamless finish. After the base structure is complete, various features such as flanges and brackets can be added as required by the project specifications.

Finishing processes, such as galvanization or painting, may also be applied to enhance the durability and appearance of the pipes, providing additional resistance to corrosion and environmental elements.

The Benefits of Automation

The shift towards automation in downspout production has numerous benefits. First and foremost, it significantly reduces the chances of human error, leading to an increase in the overall quality of the products being manufactured. Furthermore, automation helps in maintaining consistency across production runs—an essential factor for meeting customer expectations in various construction projects.

Additionally, the reduction in manual labor not only cuts costs but also allows human resources to focus on more complex tasks that require critical thinking and problem-solving skills. This transition from manual labor to automation is indicative of broader trends in the manufacturing sector, where efficiency and quality control are key to staying competitive.

Conclusion

The automatic downspout steel square and round pipe machine is a prime example of how technological advancements have transformed traditional manufacturing practices. By enhancing precision, efficiency, and versatility, these machines have become indispensable tools in the production of essential components for modern construction. As technology continues to evolve, we can expect further innovations in machinery that will not only improve production processes but also contribute to sustainability in construction practices, ultimately benefiting both manufacturers and consumers alike.