The Advancements of Automatic C/Z Purlin Roll Forming Machines

In the realm of modern construction and structural engineering, the demand for reliable and efficient materials is ever-increasing. One of the key components in the construction of frameworks for buildings, warehouses, and industrial facilities is the use of purlins. Among the various technologies available to produce these essential components, the Automatic C/Z Purlin Roll Forming Machine has emerged as a revolutionary tool for manufacturers and builders alike.

Understanding Purlins

Purlins, which are horizontal beams used to support a roof or wall in a building, come in various shapes and sizes, with C and Z being the most common configurations. The choice between C and Z purlins often depends on the specific structural requirements of a project. While C purlins are typically used for lighter loads, Z purlins provide additional strength and are favored in applications where heavier loads are expected.

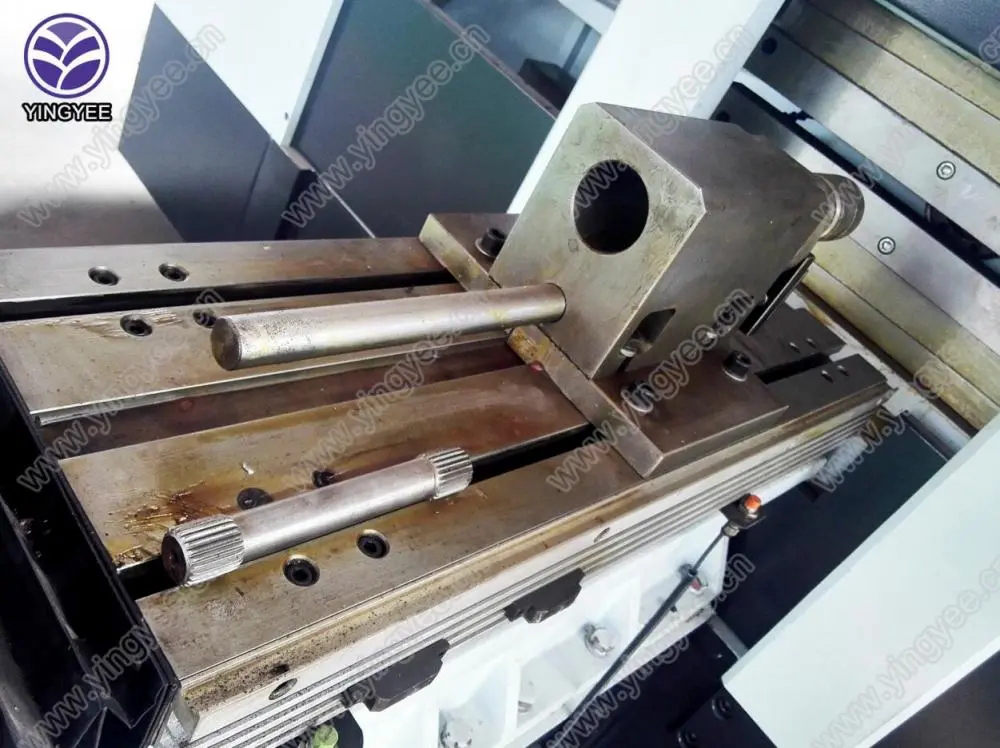

The Role of Roll Forming

Roll forming is a continuous bending process wherein a long strip of metal is gradually shaped into the desired cross-section by passing it through a series of rollers. This method not only allows for the efficient production of purlins but also ensures precision and uniformity in the final product. Automatic C/Z purlin roll forming machines take this process a step further by integrating automation and advanced controls, thus enhancing production efficiency and reducing labor costs.

Features of Automatic C/Z Purlin Roll Forming Machines

1. High Efficiency One of the defining features of automatic machines is their ability to produce purlins at a rapid pace. With advanced technology, these machines can operate at high speeds, substantially increasing output without sacrificing quality.

2. Precision Engineering Automatic roll forming machines are designed with precision in mind. Using computer numerical control (CNC) technology, they can achieve accurate dimensions and uniform thickness, ensuring that each purlin meets stringent engineering standards.

3. Material Versatility These machines are capable of working with a variety of materials, including galvanized steel, aluminum, and other metals, allowing manufacturers to cater to different project specifications.

4. Customization Modern roll forming machines can be easily adjusted to create purlins of various dimensions and configurations, making them highly versatile. This flexibility can help construction firms meet unique project requirements without the need for additional equipment.

5. Reduced Waste The automated nature of these machines minimizes material wastage, as they optimize the use of raw materials. This efficiency not only reduces costs but also contributes to a more sustainable production process.

6. User-Friendly Operation Many automatic roll forming machines feature intuitive interfaces that simplify the operation process. This allows workers to quickly adapt and operate the equipment, reducing the training time required and enhancing productivity.

Conclusion

The Automatic C/Z Purlin Roll Forming Machine represents a significant advancement in the manufacturing of structural components. By combining efficiency, precision, and versatility, these machines are revolutionizing the way purlins are produced and utilized in construction. As the demand for faster and more reliable building materials continues to grow, the adoption of such advanced machinery will likely increase, paving the way for a more efficient and sustainable construction industry.

Investing in an Automatic C/Z Purlin Roll Forming Machine is not just a step towards modernizing production; it is an investment in quality, efficiency, and the future of construction. With these machines, manufacturers can meet the evolving demands of the industry while ensuring the structural integrity and performance of their products.