Elevating the roofing and construction industry, the automatic C/Z purlin forming machine delivers unmatched precision, versatility, and efficiency. As construction demands evolve, the need for reliable, cost-effective solutions becomes paramount. This machine not only meets but frequently surpasses these demands, placing it at the forefront of modern architectural engineering.

Having navigated the intricacies of construction projects for over a decade, my firsthand experience with automatic C/Z purlin forming machines has solidified an understanding of their indispensable role. These machines transform coiled sheet metal into precisely shaped C and Z purlins—structural components that form the backbone of many building frameworks.

The secret to their efficacy lies in the automation process. Traditional methods, reliant on manual labor, are time-consuming and leave room for human error. In contrast, automatic C/Z purlin machines streamline the manufacturing process, ensuring each purlin is produced to exact specifications. This precision is crucial as it enhances structural integrity and supports the weight distribution in roofing systems.

Working with these machines reveals their versatility. The automatic adjustment capability between C and Z profiles means switching between tasks is seamless. This flexibility significantly reduces downtime, allowing for swift transitions between different project requirements. For anyone managing varying construction demands, this adaptability translates to both time and cost savings.

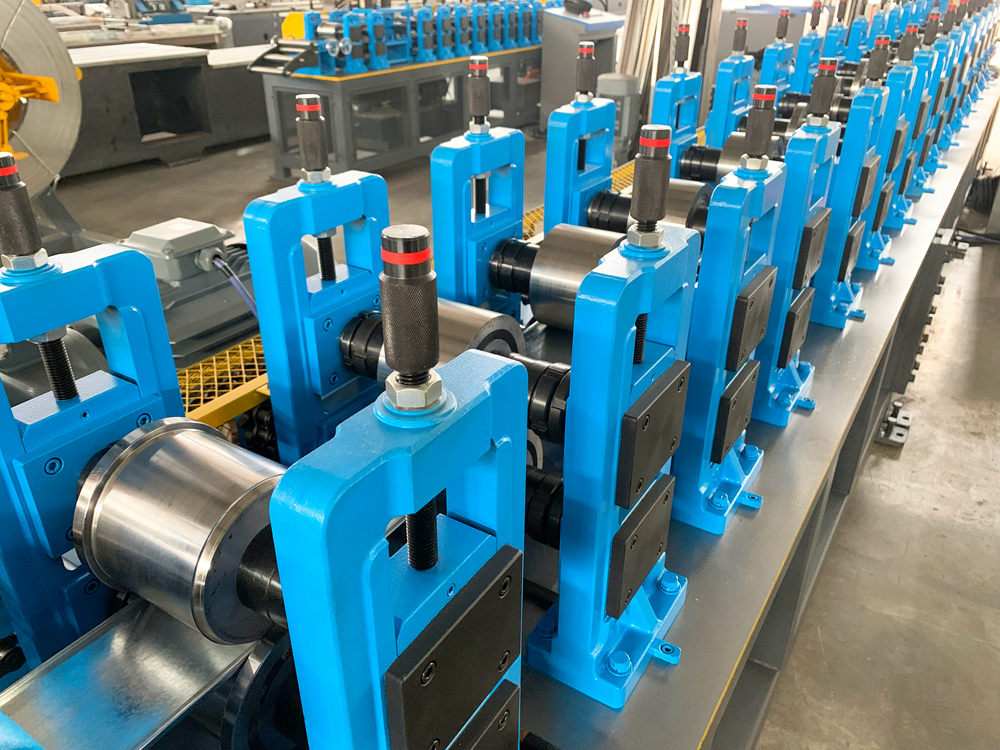

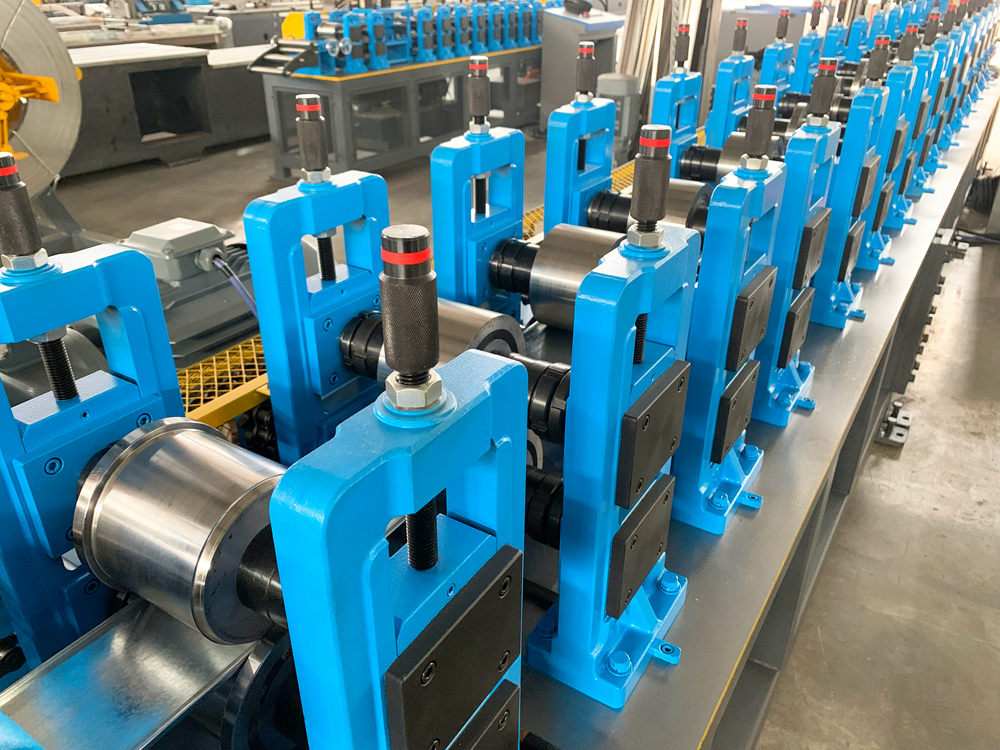

Professional expertise emphasizes another key feature—automation improves productivity. Once parameters are set in the machine's control system, it operates with minimal supervision, freeing up manpower for other critical tasks. This efficiency does not compromise quality; in fact, it enhances it. The machine incorporates precision rollers and cutting tools to ensure high-quality outputs that meet industry standards consistently.

automatic c/z purlin forming machine

The authority of the automatic C/Z purlin forming machine is underscored by its robust construction and technological advancements. Many manufacturers now imbue these machines with smart technology, integrating sensors and real-time monitoring systems. This innovation allows for predictive maintenance, minimizing unexpected downtime and extending the lifecycle of the equipment.

Trust is a cornerstone of any construction endeavor, and the reliability of these machines builds just that. They have undergone rigorous testing under various conditions, ensuring they withstand the demands of both small and large-scale projects. For project managers and engineers, this reliability translates to peace of mind—a critical factor in meeting project deadlines.

Moreover, as sustainability becomes increasingly crucial in construction, the automatic C/Z purlin forming machine aligns with these green goals. By maximizing efficiency and minimizing waste, it supports environmentally friendly building practices. Additionally, the machine's ability to optimize material usage reduces excess scrap, further bolstering sustainable practices.

The industry respect for these machines is palpable. As more professionals across the globe transition to automated solutions, the automatic C/Z purlin forming machine stands as a testament to engineering prowess and forward-thinking design. For those in search of enhancing their construction portfolio, investing in this technology is not merely an upgrade—it's an imperative step towards future-proofing operations.

In conclusion, the automatic C/Z purlin forming machine is more than a tool; it is an investment in quality, efficiency, and sustainability. Its integration into the construction landscape marks a pivotal shift towards smarter, more reliable building solutions. Through years of experience, consultation with experts, and successful implementation, its value is unquestionable. Thus, for those committed to excellence, embracing this machinery is a stride toward enduring success and customer satisfaction in the competitive construction arena.