The Versatility and Efficiency of Automatic C/Z Purlin Forming Machines

The construction industry has witnessed profound advancements with the introduction of automated technologies, enhancing productivity, reducing labor costs, and improving the quality of building materials. One such innovation is the Automatic C/Z Purlin Forming Machine, a game changer for fabricators and builders alike. This article explores the features, benefits, and applications of these sophisticated machines.

Understanding C/Z Purlins

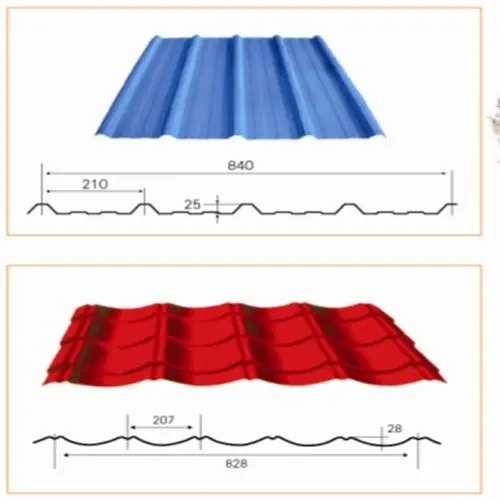

C and Z purlins are structural members primarily used in steel construction, providing essential support for roofs and walls. The nomenclature derives from their respective shapes 'C' for a C-shaped profile and 'Z' for a Z-shaped profile. These purlins are preferred due to their lightweight, high strength-to-weight ratio, and versatility, making them ideal for various applications including residential, commercial, and agricultural buildings.

What is an Automatic C/Z Purlin Forming Machine?

An Automatic C/Z Purlin Forming Machine is designed to produce C and Z-shaped purlins from a continuous coil of steel. The machine employs advanced technologies to cut, shape, and often drill or punch holes into the steel material, resulting in high-precision purlins that meet specific engineering standards. The automative features of these machines significantly streamline the manufacturing process, enhancing efficiency and reducing the likelihood of human error.

Key Features of Automatic C/Z Purlin Forming Machines

1. Customization These machines offer programmable settings, allowing users to create purlins of varying lengths, widths, and thicknesses according to project requirements.

2. High Precision Equipped with state-of-the-art technology, these machines ensure tight tolerances and consistent output, which is crucial for structural integrity.

3. Speed and Efficiency The automated processes drastically reduce the time from material input to finished product, maximizing production rates.

4. User-Friendly Controls Most modern machines come with intuitive interfaces, enabling operators to easily set parameters and monitor the production process.

5. Durability and Maintenance Built with high-quality materials, these machines are designed to withstand intensive use with minimal maintenance requirements.

Benefits of Using Automatic C/Z Purlin Forming Machines

2. Adaptability The ability to switch between C and Z profiles makes these machines versatile for suppliers catering to varied market demands.

3. Enhanced Production Capacity With the speed and automation features, manufacturers can increase their output, efficiently meeting the needs of large projects.

4. Improved Product Quality Consistent and high-quality production leads to fewer defects, enhancing the overall durability of the purlins.

5. Support for Modern Construction Techniques As the industry moves toward prefabrication and modular construction, these machines are pivotal in producing required materials efficiently.

Applications of Automatic C/Z Purlin Forming Machines

Automatic C/Z Purlin Forming Machines find application across numerous sectors

- Commercial Buildings Purlins provide essential support for roofing systems, significantly contributing to commercial construction.

- Industrial Structures In warehouses and factories, C/Z purlins are used extensively due to their strong yet lightweight properties.

- Agricultural Facilities They are vital in the construction of barns and storage facilities, where durability and cost-effectiveness are paramount.

- Residential Projects With the growing trend of metal buildings in residential areas, these purlins are increasingly utilized for framing.

Conclusion

The Automatic C/Z Purlin Forming Machine represents a substantial advancement in construction technology. Its ability to produce high-quality, customized purlins efficiently positions it as an essential tool for builders and fabricators in today's fast-paced construction environment. As the industry continues to evolve, investment in such machinery will only enhance operational efficiency, quality, and ultimately, project success. Whether in commercial, industrial, agricultural, or residential applications, the contribution of these machines is undeniable, paving the way for innovative building practices.