The Advancements in Automatic C/Z Purlin Forming Machines

In the realm of modern construction and manufacturing, efficiency and precision are paramount. One of the key innovations that have revolutionized the industry is the automatic C/Z purlin forming machine. These advanced machines cater to the growing demand for purlins, which are vital structural components used in various building frameworks, particularly in steel construction. This article delves into the features, benefits, and applications of automatic C/Z purlin forming machines, shedding light on why they are becoming the go-to solution for manufacturers.

Understanding C/Z Purlins

Purlins are horizontal structural members that support roofing and wall systems in buildings. The designation C or Z refers to the shape of the cross-section of the purlins. C purlins are typically used in applications like portal frame buildings, where they are necessary for providing support for roofing panels. On the other hand, Z purlins overlap at the joints, making them ideal for longer spans. The choice between C or Z purlins often depends on the specific requirements of a construction project, including load-bearing capacities and structural integrity.

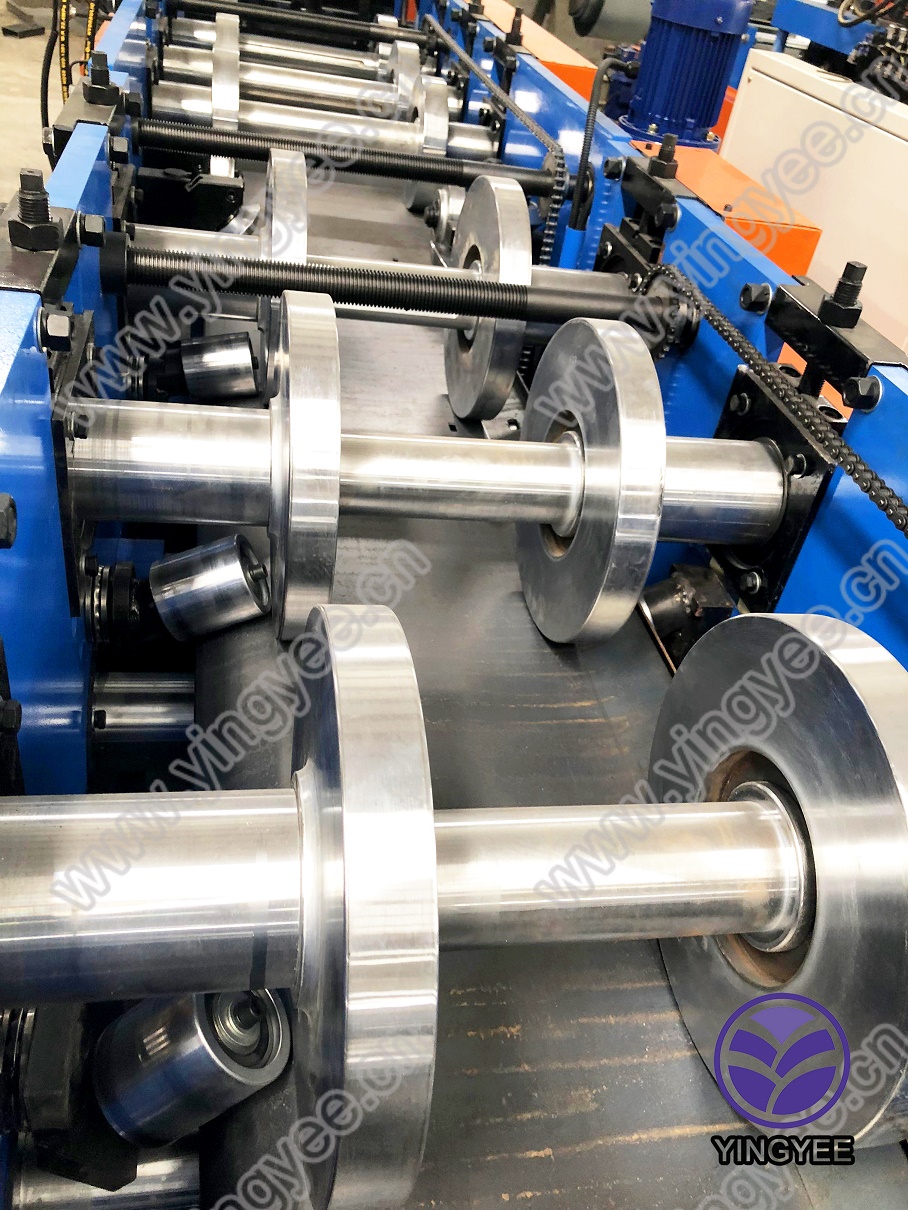

Key Features of Automatic C/Z Purlin Forming Machines

1. High Precision and Consistency One of the standout features of these machines is their ability to produce purlins with high precision. Automated processes minimize the possibility of human error, ensuring that every piece is manufactured to exact specifications.

2. Versatility Modern automatic forming machines can switch between producing C and Z purlins with minimal downtime. This flexibility allows manufacturers to meet varying client needs without significant reconfiguration of the machinery.

3. User-Friendly Operation Automatic C/Z purlin forming machines are equipped with advanced control systems, often featuring a touchscreen interface. This user-friendly design allows operators to set parameters easily, monitor production, and make necessary adjustments in real-time.

4. Efficiency With the ability to produce purlins quickly, these machines enhance overall production efficiency. High-speed operation allows manufacturers to meet tight deadlines while maintaining quality.

5. Reduced Waste Advanced technology in these machines leads to better material utilization, minimizing scrap and waste. This not only contributes to cost savings but also aligns with sustainable manufacturing practices.

Benefits of Using Automatic C/Z Purlin Forming Machines

Investing in automatic C/Z purlin forming machines offers numerous benefits for manufacturers

- Cost-Effective The efficiency and speed of these machines can significantly reduce labor costs and production times, leading to higher profitability

.- Enhanced Product Quality The precision of automated manufacturing ensures that the quality of purlins meets or exceeds industry standards, reducing the likelihood of structural issues in construction.

- Scalability With these machines, manufacturers can easily scale production up or down based on market demands, providing greater flexibility and responsiveness.

- Technical Support Most manufacturers of forming machines provide comprehensive technical support and training, which ensures that operators are well-equipped to handle the machinery efficiently.

Applications in the Industry

The versatility of automatic C/Z purlin forming machines makes them suitable for a wide range of applications

- Commercial Buildings Purlins are integral to the structural integrity of warehouses, factories, and retail spaces.

- Agricultural Structures These machines can produce purlins for barns, silos, and other agricultural buildings that require robust support.

- Residential Projects C/Z purlins can also be used in large-scale residential developments, particularly in frame construction.

- Industrial Facilities Manufacturing plants often utilize these purlins in their structures for added stability and strength.

Conclusion

The automatic C/Z purlin forming machine stands at the forefront of modern manufacturing, combining speed, versatility, and precision. As the construction industry continues to evolve, these machines are becoming essential tools for manufacturers looking to enhance productivity and meet the ever-increasing demands of their clients. By embracing this technology, businesses can not only improve their operational efficiency but also ensure that they remain competitive in a rapidly changing market.